A key highway stretch is being constructed at present in Southern Italy. The new road is the final section of the Ionian Highway, which will form part of the Trans-European Transport Network (TEN-T) as the E90. The Mega Lot 3 of the Ionian Highway is for a new section of the SS-106, from the junction with highway SS-534 (km 365+150) in Sibari to Roseto Capo Spulico (km 400+000) in Italy’s Calabria region. The work is expected to last seven years.

The project is important as it will help develop economic activity in Calabria, one of the more depressed areas in Italy. In addition, the project is one of the largest highway works underway in Italy at present.

This 38km stretch of the highway is being constructed by the Webuild Group, formerly known as Salini Impregilo. The project was commissioned by Italy’s state road agency, Azienda Nazionale Autonoma delle Strade (ANAS), with the work due for completion in 2026. The SS-106 is being designed with two lanes in either direction and this section will feature a number of tunnels, viaducts and bridges.

The total project value for ANAS is some of €1.33 billion, although this figure includes additional costs such as administration and the various legal aspects, and Webuild’s contract is worth €980 million.

Maurizio La Terza (operations manager, Domestic Operations at Webuild) explained that the section is important for Italy, because it will complete the Adriatic-Ionian-Tyrrhenian corridor. This new highway will provide an improved connection between the A2 Autostrade Mediterraneo on Italy’s west coast and the A14 Highway on the east coast, which is known as the Adriatica.

The whole of the SS-106 highway runs 491km between Regio Calabria, Calabria at the very southern tip of Italy and Taranto in Puglia and it also crosses the region of Basilicata in the middle of the two regions. This latest stretch of the highway runs along the coast of the Gulf of Taranto, following a new route away from the existing road along most of its length, although part of the existing alignment will also be used. The SS-106 is called the Jonica in Italian, meaning Ionian in English.

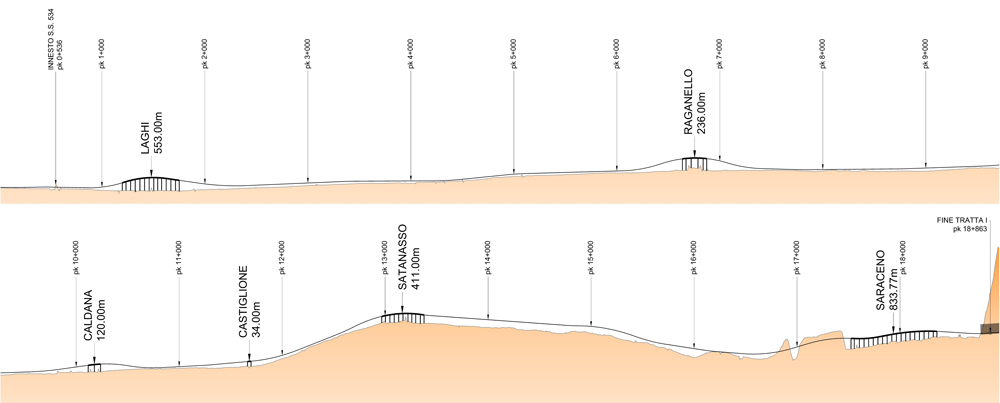

The project team (Sirjo – chairman Pietro Gianvecchio and CEO and Designer Salvatore Lieto) building this last section of the route faces a number of challenges, adding to the complexity of the work. The topography features fairly flat terrain at the southern end of the 38km route, with marine terraces and plateaux, interspersed with rivers more prevalent in the northern end. According to Lieto, the southern half of the highway crosses this flat terrain while the northern half runs along the coast and a plateau with valleys.

While the geology itself is not complex in itself, the stretch requires the construction of three tunnels that measure a total of 5km and have to be driven underground. There is also a need to build a further 11 tunnels using the cut-and-cover technique and that will measure 6km in total. As well, the project requires 15 bridges and viaducts to be built, measuring a total of 6km. The largest of the viaducts are the Avena and the Stellitano, which are benefiting from landmark designs intended to complement the surrounding area.

The historic importance of the region has presented some challenges, with the road builders having to take extra care not to damage any sites of archaeological importance. The Gulf of Taranto is the location of many important historic sites dating back to the dawn of European civilisation, including the Ancient Greek cities of Sybaris and Thurii. The famous Archaeological Park of Sybaris lies just a short distance from the route and it is likely that there are many undiscovered finds also in the area. In addition, the route passes close to the historic castle of Roseto and one of the tunnels will be constructed at this point.

The work on the project is being split into three sections. The first section measures around 18.5km and is 2-8km far away from sea, while the second measures around 15km and is 1-2km from the sea. The last section is less than 1km from the shore.

The materials being used for the civil structure of the project have been selected carefully to match the conditions, with protection for the steel used close to the sea, for example. Exposed components are being painted as required and special S460 grade steel is also being used where needed, while sulphate resistant cement is being used in the bored piles.

Two main viaduct types are being used to carry the road over the various valleys and rivers along the alignments. Some of the viaducts are designed with a triple steel girder deck that is 2.4m thick. On top of this sits the road platform with a reinforced concrete slab that is 0.3m thick, featuring both of the carriageways. Support is provided by reinforced piers with a maximum height of around 11m, while the maximum span is generally around 45m (although one span is 66m). The viaduct decks are 25.2m wide, apart from two that are wider because they are near interchanges. The longest of these viaduct types measures 830m.

The other viaduct type features a twin steel girder, orthotropic deck. The road platform is mounted directly above the top steel plate. The steel is prepared using shotblasting, with the primer then applied followed by the binder layer and wearing course. These viaducts sit on piers featuring a maximum height of 40m, with spans of 86-100m (although one span is 120m). The overall deck thickness ranges from 3.6-4.5m, while the decks are also 25.2m wide. The longest of these viaducts is 650m.

However, there is also one special viaduct that has been designed to meet both architectural and aesthetic requirements. This features a twin rigid frame bridge with orthotropic deck and inclined steel legs. It has a maximum height of 65m and a maximum span of 200m, while it measures 660m in length.

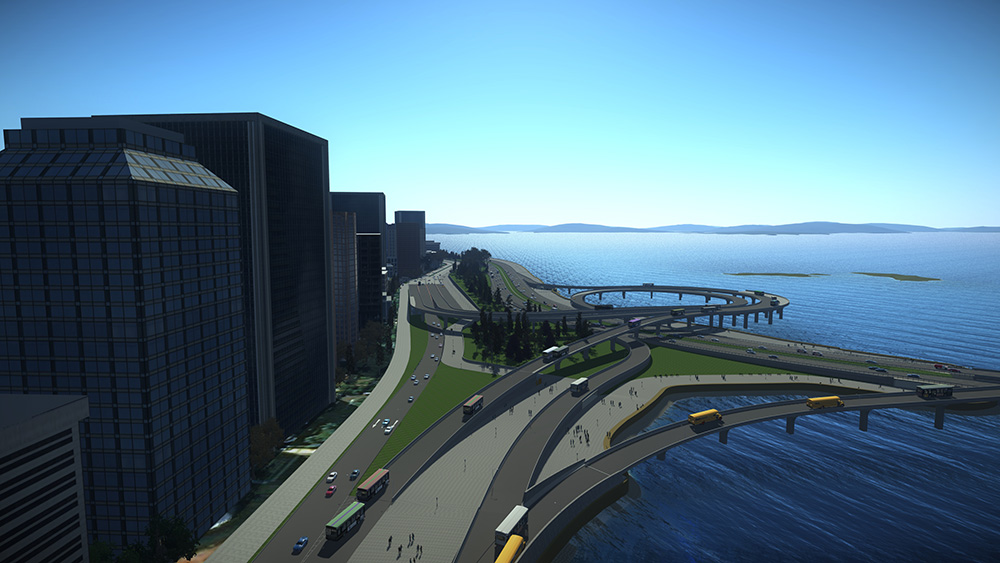

![ The builders have been careful to minimise the visual impact of the viaducts and tunnelsThe builders have been careful to minimise the visual impact of the viaducts and tunnels [Click and drag to move] ](/sites/wh/files/inline-images/Figura%20A.jpg)

For the more mountainous areas, tunnel sections are being used. The underground tunnel stretches are being driven by mechanical face work and using excavators equipped with hydraulic tools such as breakers and rippers. These sections will then be shotcreted, meshed and lined to provide the necessary support. The use of excavators using attachments to drive the tunnels was considered most suitable for the conditions. The underground sections are too short for a TBM to be considered either practical or cost effective, while drill and blast methods would also have been unsuitable both for the geology and due to the presence of historic buildings in the vicinity of the alignment (such as the Roseto Castle). The presence of firedamp (flammable gases) presents a complication for the underground tunnelling work, so necessary precautions are being taken to monitor gas levels, maximise ventilation and minimise risk. The machines used are being configured specially to ensure that they are safe, despite the presence of gas in the strata.

Meanwhile, conventional excavators and haul trucks will be used to move the material for the cut and cover tunnel stretches. Temporary retaining walls will be used as required and the tunnels will be lined and topped using pre-cast concrete elements.

The SS 106 highway is classed as a B category express road in Italian standards, with two carriageways featuring two lanes of 3.75m width each, plus a 1.75m hard shoulder and a 0.5m gap beside the barrier for the central reservation.

When running along an embankment, the roadway features a foundation layer of 250mm, with a 100mm base layer, 50mm binder layer and 50mm wearing course. When running in cuttings, the foundation layer is 200mm, with an 80mm base layer, 50mm binder layer and 50mm wearing course. For the tunnels, the foundation layer is 350mm, with a base layer of 80mm, a binder layer of 50mm and a wearing course of 50mm. On the viaducts and bridges meanwhile, the foundation is provided either by a concrete slab or an orthotropic deck. For the slab, a 60mm binder layer is used with a 50mm wearing course. For the orthotropic deck design, a waterproofing layer of 50mm is used with a 55mm binder layer and a wearing course of 30mm.

Water run off from the road will be controlled by a combination of open channels and pipes. To preserve the rivers being traversed along the route, proper water treatment is being used to prevent contamination using systems that meet the strict Italian environmental requirements.

Construction started

The laying of the foundation stone for the commencement of Mega Lot 3 of the Ionian Highway was carried out recently at Francavilla Marittima in Cosenza province. “Investment in the future of our country restarts today, here in southern Italy.

This is the moment to act, to create employment and growth thanks to great infrastructure that can transform Italy and take it towards the future,” Webuild chief executive Pietro Salini said at the ceremony held for the laying of the first stone. “And the issue today is not so much having a new infrastructure programme, with the risk of having to wait years before being able to lay the first stone, but to plan and build public works quickly, simplifying procedures and guaranteeing liquidity to businesses.

Many projects are already ready on paper and the economic resources are there to get them going immediately, from hospitals to road maintenance, from new metro lines to new railways. What is expected of us after the COVID-19 emergency is a revolution in our way of thinking, something that goes beyond just economics, something that we must address it together. In Italy, we dedicate less than 2% of public spending on infrastructure. It is a choice that has us missing the train towards a more modern country in terms of mobilty and multi-modal transport, all of which are essential for us to grow and push forward a sustainable development plan.

From high-speed railways to road networks to metro lines, Italy needs to modernise. The emergency has become an alibi for this country. We think of Genoa where we are building the new bridge in record time because everyone is rowing in the same direction. It is not because of some extraordinary procedure. Only with this spirit will we be able to make a leap towards the future. And Webuild is ready to do it. The stone being laid today is also one for our new company, because the construction site for this road is where Webuild starts to work as a single Group: bigger and stronger,” he said.

Archaeology and historic structures

Sybaris is one of Southern Italy’s most important archaeological sites but has only been excavated partially. The site includes the remains of the settlement founded in the 7th century BC, the classical city layout designed by Hyppodomus of Miletus, and the later Roman settlement.

However, the site is at risk from groundwater that covers many of the remains as well as by the flooding from the nearby the River Crati.

Sybaris was founded in 730-720 BC and became an important city of Magna Graecia. The city thrived on trade but was attacked and destroyed in 510 BC, with the survivors then leaving for the safety of Greece. The city was resettled in 444 BC by a new Athenian colony but was renamed Thurii.

The city was settled later as a Roman colony and renamed again, this time as Copiae, before taking the earlier name of Thurii once more. Benefiting from fertile land, it was occupied until the Middle Ages.

The archaeological excavations are not complete at the site and most of the ruins uncovered are from the Roman city of Copiae. However, research in the area has revealed much earlier habitation dating back to the Iron Age. Even earlier remains have been discovered dating back to the period before the Greeks arrived. All the artifacts discovered so far are kept in the nearby National Archaeological Museum.

Meanwhile, the existing coastal road also runs past the Roseto Castle, which sits overlooking the shoreline. This dates back to Norman times and was constructed on a much earlier religious building. The castle was built to defend the Ionian Coast and became heavily fortified in the 13th century when under the control of Frederick II of Swabia. The castle continued being modified and adapted until the 16th century.