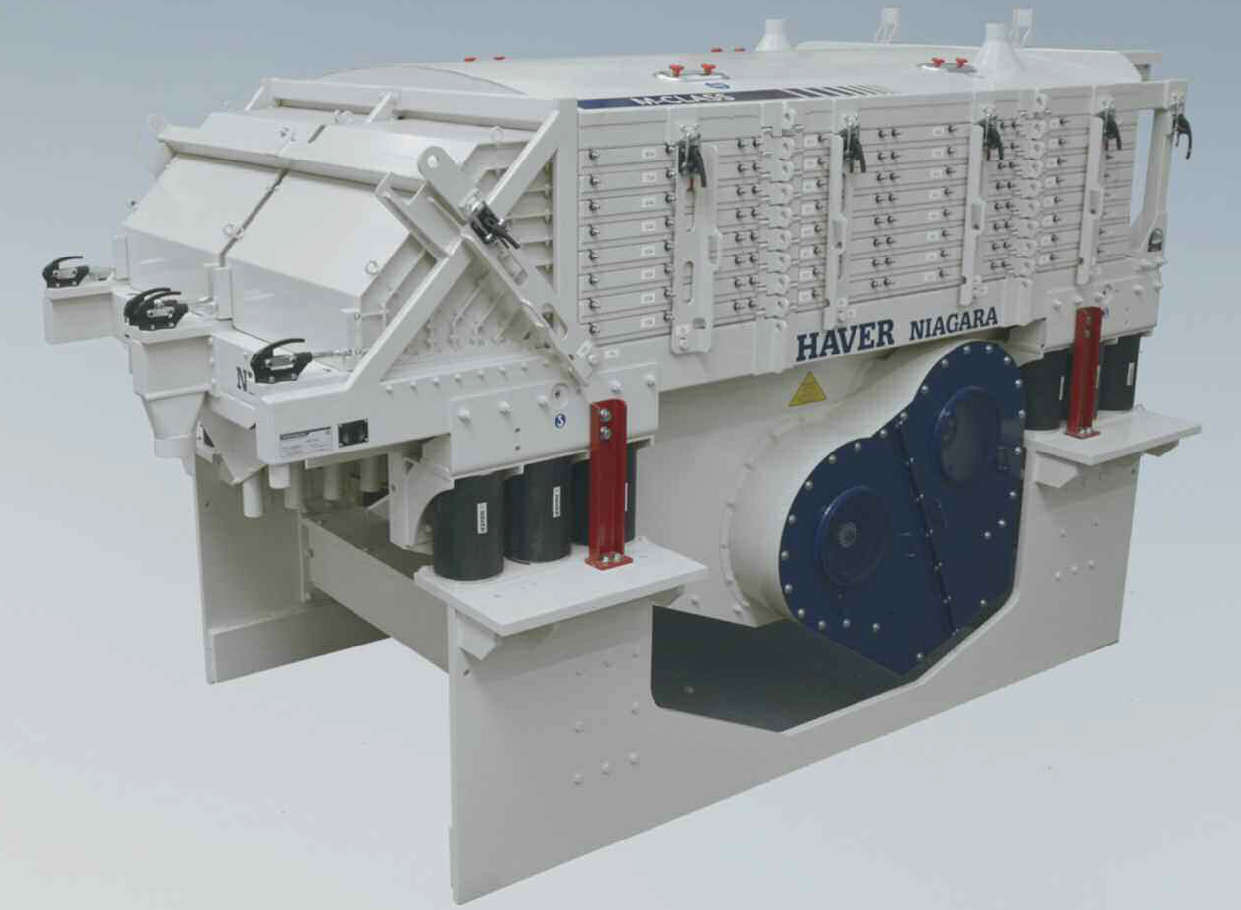

Haver & Boecker has further developed its Niagara M-Class to optimise the different features of its predecessor models and add an even more high-performance multiple-deck screening machine to its product line.

“The Niagara M-Class is the optimum solution when it comes to fine and ultra-fine particle ranges and when multiple cut sizes are needed and cut size precision is increasingly essential,” says the company.

The application range of linear vibrating screens is broad, and the system is used for cl

The Haver & Boecker Niagara M-Class 2000x2800 8D

“The Niagara M-Class is the optimum solution when it comes to fine and ultra-fine particle ranges and when multiple cut sizes are needed and cut size precision is increasingly essential,” says the company.

The application range of linear vibrating screens is broad, and the system is used for classifying industrial minerals, foodstuffs, chemical products, ores and metals.

Depending on the design, the multiple-deck screening machine has a vast screen surface (58m² of screening surface), while at the same time is characterised by its space-saving feature, says Haver & Boecker.

“In modular design the individual screen frames are horizontally stacked above each other and serve to act as the frame of the machine. The ability to later adapt the machine, for example in order to increase material throughput, is yet another advantage of its modular design,” says the company.

“The machine’s further development ensures even more exact screening results and prevents screen cloth clogging. The number range has therefore been extended from 2G to 4.5G. Depending on the task at hand, the frequency and the amplitude are adjusted accordingly.”

The Niagara M-Class is offered in two sizes, and in addition to its cut size, the machine also includes the classification of up to 11 different product fractions with only one point of transfer for each fraction.

All videos