Size options range from 1.2m x 2.4m and up to 2.4m x 6m, as well as 2.4m x 7.3m with a twin shaft. The standard model is inclined at 20°, but variations between 15-25° are available.

The unit’s body has non-welded side plates which eliminate cracking along the seams, according to the company. The shaft housing includes extra-wide flanges for Huck bolting through the tube housing flange, side plate and side plate stiffener. This allows maintenance crews to keep the factory seal and creates a very rigid and solid connection to resist the area’s high bending moments.

Haver & Boecker designed the side plates to extend behind the bearing housing, allowing the 425.5mm-high tensile strength bolts to sandwich the side plate, reinforcing plate, shaft housing and bearing housing together. This creates even more stiffness in the middle of the machine where it’s most required to withstand bending and twisting.

The manufacturer also forms the reinforcing plate with 90° vertical edges to give the side plate stiffness from top to bottom, tying the upper and lower decks together for additional strength. Rigid body brackets manufactured to withstand large static and dynamic loads support the body weight and carry through to the springs, ensuring smooth operation.

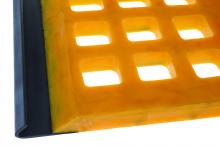

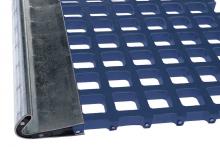

Haver & Boecker equips every cambered deck on a T-Class with its Ty-Rail quick-tensioning system, which cuts screen media change-out time by about half. Each Ty-Rail package includes two tension rails, eight angle boxes and eight bolts. To remove the tension rails, an operator loosens the bolts on each, shifts the angle box gates up and lifts the rail and bolts out as one piece.

The T-Class can be paired with any type of screen media, including Haver & Boecker’s Tyler engineered media, including the long wear life of Ty-Wire, Ty-Max and Ty-Deck.

Haver & Boecker also offers the Pulse vibration analysis programme to monitor the ongoing health of vibrating screens through real-time views, logged reports and data analysis. It’s designed by Haver specifically for vibrating screens to catch small inconsistencies before they grow into big problems that result in downtime.