Norway’s road transport network is undergoing a radical transformation, which seems to be happening without widespread international recognition. There are two massive changes underway, which are separate but at the same time are also connected. Firstly, Norway is seeing an increase in the number of EVs on its road network, which may come as a surprise to some given the country’s status as a major oil producer. Secondly, the Norwegian Government has committed to replacing coastal ferry routes with either tunnels or bridges.

Both of these are factors in Norway’s long-term aim for a more sustainable transport future, with less energy being expended and fewer carbon emissions. There are considerable technical as well as geographic challenges however.

Norway’s long coastline is extremely scenic, its often rugged fjords rightly famed for their beauty. But road transport has long been a challenge for Norway, a country that also has a long history as a seafaring nation, dating back at least 1,000 years. For anyone driving along Norway’s coastal areas, ferries have provided vital transport connections across fjords and to outlying islands.

The policy on replacing the ferry links has seen many bridges being constructed, including a number of novel designs such as wooden bridges and floating bridges. Similarly, the country has invested in the construction of tunnels, including the longest underwater road tunnel ever built.

The country opened its first subsea tunnel to traffic in 1982, the Vardø Tunnel, while the Lærdal Tunnel has become the world’s longest road tunnel, at 24.5km. This links Lærdal and Aurland in Sogn og Fjordane, to the north of Bergen and forms part of the important E16 European Route.

Meanwhile, tunnel connections have also been constructed in Norway’s cities, providing road connections in urban areas. These have helped take the bulk of traffic away from populated areas, boosting safety for pedestrians for example.

From a technical perspective, Norway has many advantages when it comes to tunnelling as it is geologically stable and features competent rock in many areas. Tunnels driven by drilling and blasting or TBMs can be bolted, shotcreted and lined using comparatively straightforward methods in many instances, unlike other countries where factors such as earthquakes or poor rock conditions may have to be considered. While Norway is extending its road tunnel network significantly, the fact that most projects are being carried out in good conditions does present a mitigating factor for the overall construction costs.

Linking an island chain

The country’s latest, highly ambitious, bridge and tunnel project is for the construction of the Nordøyvegen, The North Island Road. This is intended to link the northern islands of Haram Municipality and Sandøy Municipality to the mainland in Møre og Romsdal county.

The aim of the project is to replace the ferries that currently connect the islands with a series of tunnels and bridges. The plan will see new fixed links crossing four fjords, while a number of existing roads on the islands will also benefit from key improvements, allowing them to meet the latest safety standards.

The work is costing an estimated €492.3 million (NKr 5 billion), allowing the 3,000 or so inhabitants on the islands to travel to the mainland without having to rely on a ferry service. This will speed journeys to and from the islands for the residents and is also expected to deliver a much-needed boost to tourism for the highly scenic islands.

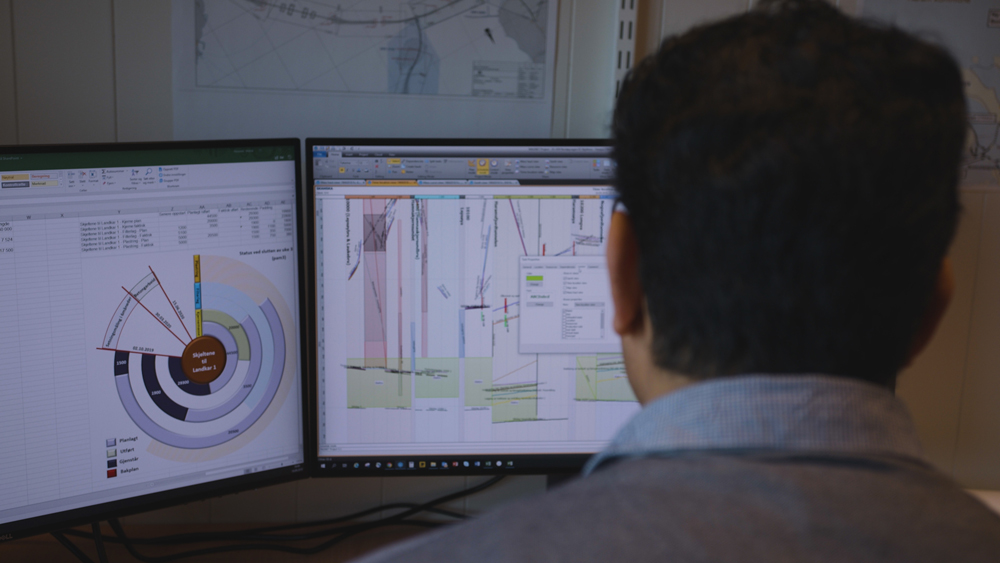

Building this new transport link has presented major challenges however, so the contractor appointed for the work in the third quarter of 2018, Skanska, has taken care to employ some of the latest technology. Even while preparing its bid for the work, the company made considerable use of the sophisticated MAGNET software package from Topcon Positioning to better analyse the scale of the works required.

The vast scope of the project, and the numerous engineering challenges it presented, required Skanska to carry out extensive planning well in advance. By using the software package, Skanska was able to deliver a comparatively accurate forecast of its construction needs and project costs, helping to optimise its tender and also assisted in winning the bidding process. The contract for the project was awarded to Skanska by the Norwegian Public Roads Administration (NPRA).

Planning is crucial to the operation, which will provide links from the mainland to the chain of seven islands; Lepsøya, Hestøya, Haramsøya, Skuløya, Fjørtofta, Harøya and Finnøya. There are two existing bridges that will form part of the new road connection, but the project will add three new bridges as well as a new causeway, providing a total of 8km of new road. In addition, there are three long undersea tunnel stretches being bored, which measure nearly 13km in total.

Construction commenced in 2019 and has been planned for completion in the second quarter of 2022. The use of the software has been crucial as it allowed Skanska to plan its works more accurately than would otherwise have been possible. This planning has all been carried out in a digital format, helping to make the construction process more efficient. Using this digital model has allowed the engineering team to analyse the alignment and design effectively, addressing the issue of clash detection, which helped to reduce costs from the commencement of construction.

Data from the design model is transferred seamlessly to the separate construction operations in advance, allowing more efficient working. This ensures that the correct alignment is adhered to and optimises the tunnel excavation process, a significant cost saving. Drilling and blasting has been used to drive the tunnels, with conventional tunnelling jumbos being utilised for the work. Recovered data from the tunnelling operation meanwhile provides precise updates to the project models, showing what work has been carried out and when this was done.

Skanska is employing an unusual method in that the firm is using the rock it removes during the tunnel driving operation and then utilises this material in the construction of the bridges. This ensures minimum waste from the operation while also reducing the overall carbon profile of the project, as far less material needs to be trucked in from quarry operations elsewhere in the country. In addition, this minimises waste while removing the need for excavated rock to be disposed of elsewhere. However, it does complicate the construction operation as scheduling material flow from one side of the operation to the other, from the tunnel face to the bridge building operation, has become more crucial.

Lepsøya Island and Hestøya Island lie at the southern end of the chain, linked to the mainland by the Lepsøy Bridge, Lauvøy Bridge, and Hamnaskjersund Bridge respectively. As the sea is not deep at this point, the three bridges are integrated into a causeway structure, which is being built using the material recovered from the tunnelling operation. This stretch of the link has also been designed with a roundabout lying offshore.

Between Hestøya Island and Haramsøya Island is the Haramsfjord Tunnel measuring 3.5km, which has been providing a supply of blasted rock to build the causeway. One of the two existing bridges links Haramsøya Island to Skuløya Island and is being integrated into the new road connection. Meanwhile, a new 5.73km tunnel is connecting Skuløya Island with Fjørtofta Island; and a 3.68km tunnel, the Fjørtoftfjord Tunnel, runs under the sea between Fjørtofta Island and Harøya Island. Excavated rock from these two tunnels is also being used for construction elsewhere in the project. Lastly, the second of the existing bridges then connects Harøya Island with Finnøya Island.

The integration of the tunnel face excavation, rock transport and causeway construction operations has been vital to ensure that enough material is available when required. This has been managed using the digital tools in the software, which has allowed Skanska an overview of its respective operations in real time. Production of the rock from the tunnel faces has had to be balanced continuously against the demand for rock for use in the causeway.

Delays in material supplies from one side of the operation to the other would result in the timeline of the entire project being lengthened, with the unfavourable outcome of considerable increases in overall construction costs.

The use of the software has meant that Skanska can plan its separate operations in advance, oversee them continuously and at the same time, integrate the working of each different section. The ability to optimise material haulage and flow has been crucial, with the technology providing a real time view of the entire operation. The system has allowed the construction team to work around hold-ups in any particular area, so as to deliver a more constant workflow overall.

The software has allowed Skanska to determine accurately how much rock has been required for the causeway construction. At the same time, the engineering team has also been able to predict how much rock each tunnel section will realistically deliver for the construction work. Using the software means that the quantities of excavated rock are monitored in real time. In addition, the engineers have been able to make sure that the construction operation receives the correct quantities of materials in the right place and at the right time for building work to continue. The software also shows what rock was placed where during the causeway construction operation, further adding to the project model.

Given the length of the project, this ability to track excavation, haulage and construction operations simultaneously has been vital. Skanska has been assisted with the software use by Digital Construction Works, a business established jointly between Topcon Positioning and Bentley Systems.

An EV future

Norway has been a major oil producer for many decades. Yet Norway is amongst the leaders in Europe, and also worldwide, of the widespread introduction of EVs for personal use. The country’s EV population is fast-growing as drivers replace their older internal combustion engined cars. The country had aimed to have 50,000 EVs on the road by 2017, but this was achieved two years early in the second quarter of 2015. By mid-2020, there were over 300,000 EVs on Norway’s roads, accounting for 15% of the country’s private car fleet and there are no signs that the switchover to electric cars is faltering.

While direct purchase incentives for buyers of EVs are being reduced in Norway, there are still other incentives such as lower taxes and easier parking in urban areas. This has not come without controversy, with the fact that EVs having been allowed to use bus lanes in major cities attracting increasing criticism. Users of EVs also do not have to pay for their cars to use ferries, which has attracted criticism from ferry operators as the number of EVs has increased. Each vehicle occupant still has to pay for ferry use however.

It is of note that the concentration of EVs in Norway is strongest in the largest cities, capital Oslo and the second city of Bergen. In more rural areas drivers still rely on conventional diesel or petrol cars, where charging facilities are fewer and far between.

With Norway’s EV population still growing, there is a major link with future tunnelling projects also. As EVs have zero emissions, tunnels built in coming years will have lesser requirements for ventilation. At present, extensive ventilation technology is required to remove vehicle exhaust fumes that are hazardous to health, particularly diesel particulate matter. But with more EVs on Norway’s roads, this need for ventilation will be reduced significantly. And given that proper tunnel ventilation can be costly, this will in part mitigate the spending required for future road tunnel links.