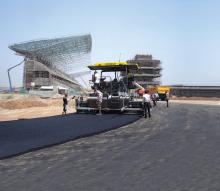

In November 2012, the new Circuit of the Americas (COTA) in Austin, Texas, hosted the first ever Formula 1 US Grand Prix on a purpose-built track. But, as Jeff Winke and Guy Woodford report, the construction of COTA was just as demanding as competing in an F1 race itself

For COTA construction contractor Austin Bridge & Road, L.P., nothing was more vital to the successful building of the 5.5km F1 track than meeting the strict criteria for its asphalt-paved surface.“The amount of stress this pavement will undergo is tremendous,” said Richard Mills, vice president of operations for the Dallas-based company. “It’s not downward stress; it’s shear stress. So, as a result, the specifications for paving are extremely stringent. These include very tight gradation requirements on the aggregate and extremely high performance requirements for the bitumen or liquid asphalt.

We also had very tight control factors relative to temperature and consistency of the material itself. It was a big challenge to accomplish all of that.”

KEY FACTS

Established in 1906, Formula 1 is the highest class of single-seater auto racing. In 2012 there were 12 racing teams, with an average team budget of US$150 million a year, whose cars raced in 20 events on purpose-built tracks or public roads in 19 countries across five continents. The annual global television audience for the F1 championship is 600 million people.

“We needed consistent practices throughout,” explained Mills. “We needed to deliver the asphalt to the pavers at the consistent temperature and without interruption. It was critical that we continuously progress the pavers, making sure the paver consistently placed a thickness that did not exceed 1/8th of an inch tolerance. That was a big challenge!

“We also completed subgrade preparation, flexbase, and asphalt for the side roads, parking lots, the pit lanes, and the service roads inside the track.”

In all, the US$33 million track paving part of the near total $400 million COTA project required 344,730tonnes of flexbase and hot mix asphalt throughout its 364hectare site. The racetrack itself required 81,630tonnes of asphalt: 45,300tonnes for the base; a 16,326tonne binder layer; and the wear layer required 19,954tonnes.

To help maintain the material’s required minimum temperature consistency of 302°F and to help ensure that a continuous flow of asphalt fed to the three high-density pavers during the track surface build, Austin Bridge & Road used two

The Roadtec Shuttle Buggy MTV is designed to “shuttle” the hot mix asphalt from the haul truck to the paver. The Shuttle Buggy features a patented anti-segregation auger that remixes materials to eliminate aggregate segregation and temperature differences.

The Shuttle Buggy MTV also supports non-stop, continuous paving, which was critical for Austin Bridge & Road’s ability to meet the pavement specifications.

“There was no wiggle room in the specs,” said Mills. “We needed the paved surface to be smoother than smooth throughout the racecourse.”

The 22.7tonne capacity of the larger Roadtec SB-2500D Shuttle Buggy, compared to the smaller units in the company’s MTV product line, was said to give Austin Bridge & Road the ability to deliver an incredibly smooth pavement.

“We took advantage of the Shuttle Buggy’s ample storage capacity to smooth out our truck cycles and prevent paving disruptions,” added Mills. “The Roadtec MTVs helped give us confidence that we knew we always had enough material there to feed the pavers.”

The Roadtec Shuttle Buggy’s truck unloading capacity is rated at 907tonnes/hour, and paver loading capacity at 544tonnes/hour.

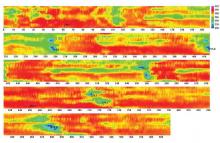

Once the mix got to the paver, the engineers’ visual and testing evaluations specifically looked for the hot mix asphalt (HMA) texture to be “homogeneous”, while maintaining appropriate temperature consistency in delivering the asphalt mix to the pavers. The expectation was for uninterrupted paving. Furthermore, the elevation of the paver screeds needed to maintain thickness tolerances that did not exceed the 3.22mm requirement.

“Typically we would lay flex base using blades and rollers but we were after tighter control,” said Mills. “We needed to control the thickness, density, consistency and smoothness, and we achieved that by using

the paver.”

The second layer placed on top of the flex base was a 7.87cm course asphalt base: a standard HMA mix, which was placed by the paver.

For the binder and final wear lifts, the engineering firm spelled out all of the proprietary custom-mix physical properties of the material, the control requirements, and the finish results required for a high-speed precision racecourse.

“We’ve never worked on a paving project before that has this level of control and specificity,” said Mills. “It makes sense that they’re expecting near perfect conditions to optimise the performance of these elite F1 drivers.

If you were to show these requirements to most paving companies, they’ll likely say the third course is near impossible to achieve, while the top, final course would be impossible.

These paving factors are very, very stringent and just meeting the specifications is an accomplishment; we’re proud to have done so.”

Mills credits Brian Arent, quality control manager for Austin Bridge & Road, for developing a plan that requires precision execution and then taking responsibility for executing it.

“There are two keys to the success of the project,” explained Mills.

“The first was the unwavering commitment to succeed on the part of our people. Everyone wanted to make sure we met these stringent specs. And the second was a very high level of collaboration among the technical people on how to execute the project, the raw materials providers on meeting the specifications, the subcontractor who performed the mixing portion, and the equipment suppliers to ensure we had the right machines, support and contingency plans should there be equipment failure.“

Supplied by Closner Equipment, San Antonio, Texas, Arent said the Roadtec SB-2500D Shuttle Buggy MTVs played a significant role in Austin Bridge & Road’s success.

“The Roadtec Shuttle Buggies were not a requirement in our specs but for us they were necessary on this project,” said Arent.

“They gave us additional mixing activity to ensure the critical material consistency we needed and they gave us additional storage that minimised the possibility the pavers would stop during the paving process. It was clear to everyone that the pavers could not pause or stop if we had hoped to achieve the smoothness we wanted and needed. Considering the end result specifications on this project, I would have felt less confident and extremely nervous about achieving the results if we did without the Roadtec Shuttle Buggies.”

The pavers selected by Austin Bridge & Road for the COTA project were the Super 2100-2 pavers with AB 600-2 TP2 high-compaction screeds from

The small HD 14 VV compact roller was used for rolling up against positive and negative curbs, and also had an edge-rolling attachment to place a bevelled edge on the lifts. The HD+ 120 VV HF rollers were kept in reserve for use on the wearing course, when the roller configuration would change. Also, a Vögele Super 800 paver with AB 200 TV screed was employed to pave some narrow run-off areas bordering the main line.

A

"Unique products from all three Wirtgen Road Technologies brands played critical roles in getting the track exactly the way it should be for its first race in November 2012," said Jim McEvoy, president, Wirtgen America. "It was the winning combination of high-performance equipment from Vögele, Hamm and Wirtgen that provided an ultra-smooth surface with just the right amount of friction essential for a safe and successful race."

Austin Bridge & Road had a minimum of three pavers and two shuttle buggies working effectively side-by-side at any one time during the COTA track-laying works, allowing the 100-year-old firm, which has been under employee ownership for 25 years, to complete their crucial part of the project within the allotted 391 days.Also assisting the firm’s project construction team throughout the works were representatives from Rodriguez Engineering; AMS; APAC-Texas; Capital Aggregates; NuStar Energy; Wirtgen; Cooper Equipment; Tilke; and Hart Consultants.

“It helped us get a real feel for the expected end result and to collaborate with the design engineer at Tilke and [asphalt expert] Dr Rainer Hart,” said Mills. “It also enabled us to witness some of their testing methods to make sure that we had the capacity for the type of tests they wanted us to do.”

Mills said the Nurburgring visit, along with a visit to Dr Hart’s laboratory and the Wirtgen Group’s facilities on the same fact-finding trip, also increased his and his team’s confidence in delivering the COTA project.

Of Dr Hart’s laboratory, Mills said: “It was a very well thought out layout, very meticulous. It was refreshing to just be able to hear from Dr Hart and understand how he looks at things. It inspired me to send some of my folks out there and bring back ideas. In our two main testing laboratories we now have a higher emphasis on keeping things organised, and in the meticulousness of our testing."

COTA golden future

Of the initial impact and long-term benefits of the new Circuit of the Americas (COTA), the track’s vice president Julie Loignon said: “The 2012 Formula 1 United States Grand Prix was a huge success and an incredible first event as it marked the return of F1 to the United States.

“COTA is expected to have a significant economic impact on the region through job creation and tourism related to our year-round programming. We look forward to hosting a variety of world-class motorsports series, concerts and major events at our track for years to come.”

On the visit to the Wirtgen Group’s facilities and their overall relationship with Austin Bridge & Road in the COTA project, which saw Austin Bridge & Road staff working on Vögele pavers and Hamm rollers, Mills added: “Building that relationship was extremely important. They allocated resources to ensure that the equipment component of the project was a major contributing factor to overall success. They thoroughly educated us on the use of the equipment and had key people on the ground throughout construction.”

Mills said a trip by some of the Austin Bridge & Road team to Moscow, Russia, in summer 2012 to see the Moscow Raceway and talk to the track’s construction engineers, Tilke, and the track’s management also proved invaluable.

“It allowed our people to see that kind of [motor sport racetrack] paving in person and how it works. It showed that instead of having a supervisor for each crew you can have a supervisor for each [construction] activity, such as a supervisor for rolling activity. It was also interesting to see they could break the track up to form more than eight different configurations.”

Mills believes that the success of the first F1 race at COTA in November 2012, and the plaudits Austin Bridge & Road and its construction partners received for the quality of the circuit, has created great business opportunities for the Texas firm.

“It was really rewarding to be part of this project. At the time of that [F1] race, we had close to two years invested in this. The track was given the highest quality classification by the FIA (Federation Internationale de l'Automobile), and we learned a tremendous amount of quality construction techniques.

“Any type of performance-based venue where people come to watch superstars, everything needs to be of the highest level of quality. We’ve shown that we have the capacity to achieve that level of quality.”

Trimble GCS900 for COTA

Austin Bridge & Road survey department manager Matt Hollensworth said that during the COTA project the firm had become the first in the world to use the

He said the use of the Trimble GCS900 Grade Control System, in particular, was crucial to the COTA project being completed successfully. “We used it to do the flex base and all the asphalt paving. There was no set up for string lines,” said Hollensworth. “Looking back, we would not have been able to pave the track in the timeframe we were given without it.”

Hollensworth said that prior to Austin Bridge & Road’s use of the Trimble GCS900 Grade Control System on the COTA project, no 3D grade control system had ever been used in the U.S. state of Texas for highway asphalt works. COTA is also the first Formula 1 track to ever use 3D asphalt paving technology.

“We have a couple of our pavers equipped with the GCS900 in use on two highways jobs, one in Dallas County and another in the Fort Worth area. They are getting fantastic results,“ added Hollensworth.

During the COTA project, Austin Bridge & Road also used the GCS900 on a Wirtgen W210 milling machine to do smart repairs when there was a design change to the project.

Tilke’s COTA dream

Christian Epp,

Epp said choosing the perfect site for the COTA track was down to cost and “location, location, location." He explained: “You need to ask questions like - has the site good topography? Are there close amenities, such as an airport? Once we chose the piece of land, we began to look at the masterplan.”

After compiling the masterplan and sourcing local civil engineers, architects and soil specialists, the small project planning team including Epp chose Austin Commercial as the main contractor, and Austin Bridge & Road for the crucial circuit paving works.

“We visited Austin Bridge & Road and explained what we wanted. We went to Germany [Nurburgring] and Moscow [Raceway] and put them in contact with companies with specific machines, as well as Dr Rainer Hart who we hire to work with us on these types of assignments. He developed the asphalt mix and specification for COTA.

“Dr Hart looked at the building techniques and machines used by Austin and advised them about the special requirements for racing and doing some things in a different way.