Italian tyre supplier Marangoni says it is seeing demand for retreaded tyres for use with off-highway haulers in particular. Marangoni’s headquarters is located at Rovereto in north-east Italy and the extensive facilities on site include the biggest tyre retreading factory in Europe.

The company says that it is experiencing strong demand for retreaded tyres as these are 40-50% cheaper than new premium brand tyres. Using four different compounds and the same process as making new tyres to make their retreads,

In total, Marangoni offers 280 different retread tyre products subdivided into 61 sizes and 42 patterns. These include retreads up to a rim of 1.295m for rigid dump trucks with a load capacity of over 100tonnes, and to a rim up to 1.143m for wheeled loaders.

The company is also keen to stress that the reduction of tyre cost/hour has become an increasingly crucial factor for all firms working in quarries and construction. Ecology is said by Marangoni to rank alongside innovation and technology as key to its work.

Retreading tyres rather than discarding them and buying new ones, according to the firm, reduces the quantity of scrap tyres in the environment. This helps lower CO2 emissions up to 30% and also energy consumption; and the process also reduces the use of raw materials.

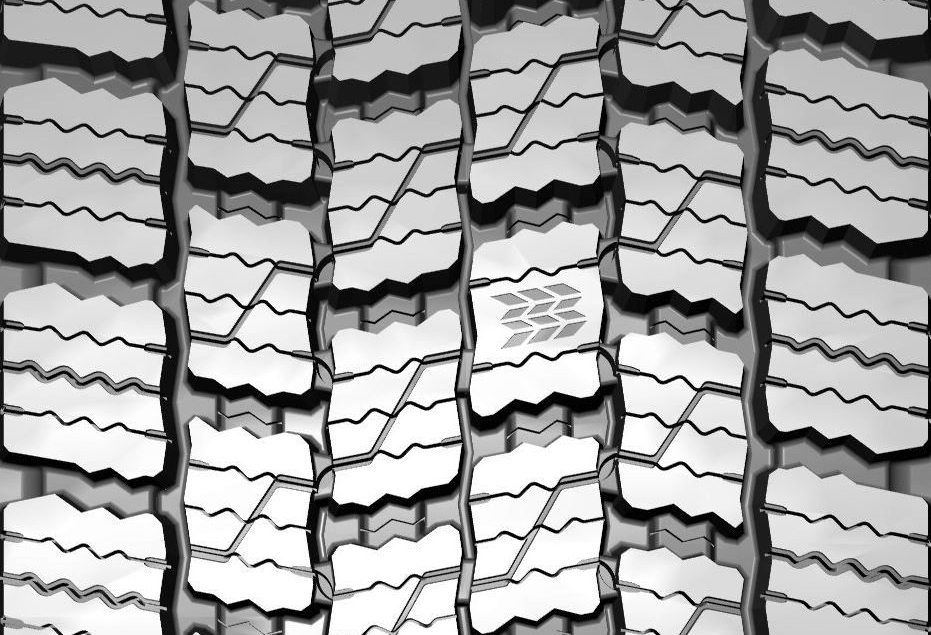

The firm recently introduced its new winter range of Blackline Ringtreads with the presentation of the WS101 pattern. This new-generation product meets the demands of extremely competitive and selective markets, thanks to its ability to combine traction and mileage, above all on roads covered by ice or compact snow.

The square tread profile provides a wide footprint that maximises grip, allowing the tread to adapt to continuous changes in both road and weather conditions. In addition, this tread is the first to bear the Marangoni logo directly on the pattern. The profile is made using a specially developed compound that ensures better rebound at low temperatures and reduced rolling resistance, as well as longer tread rubber life in extremely stressful conditions.