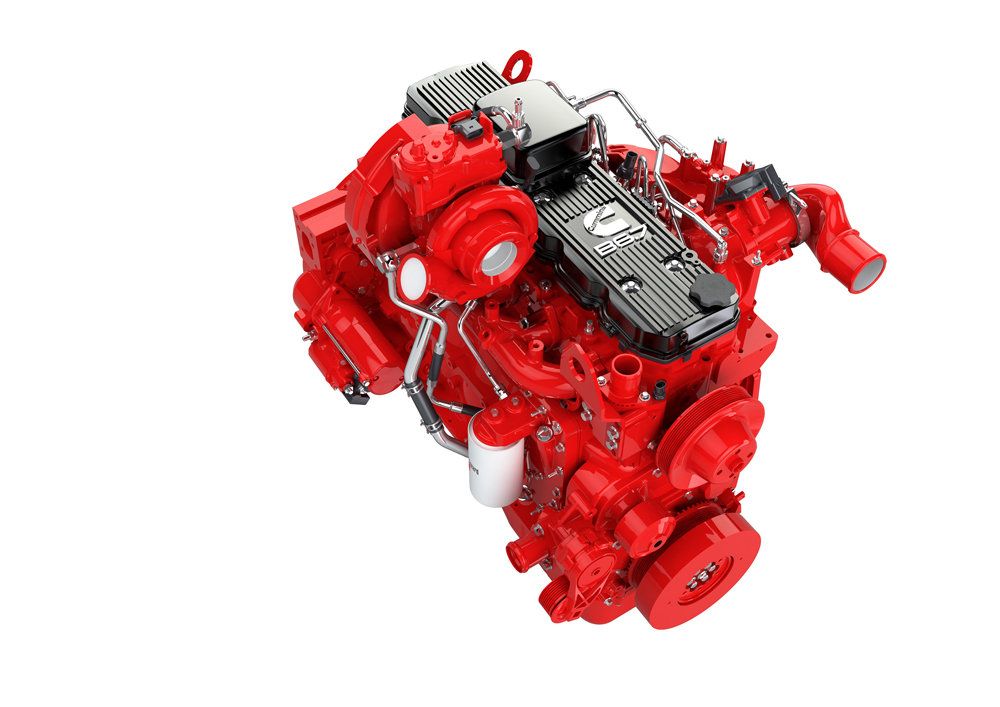

The firm is best known for its diesels but is investing heavily in developing new power sources for mobile machines, including both electric and hydrogen technologies.

Hydrogen is seen as a particularly important future fuel. It can be used in fuel cell stacks to generate electricity for both fixed and mobile machinery, with the only emissions being water vapour.

Cummins president Tom Linebarger said that to meet the challenge of tackling climate change, there must be a transition to renewable power. “We must limit carbon emissions. We believe hydrogen will play a part in that transition. Hydrogen is green and it can be produced without carbon emissions.”

He said that, at present, the majority of the world’s 70 million tonnes/year of hydrogen production (around 98%) is ‘grey’, requiring the use of methane and resulting in CO2 emissions. Meanwhile, around 1% of hydrogen production is ‘blue’, with CO2 being sequestered using former underground mine facilities as storage for example. Just 1% of hydrogen at present is truly green, using electrolysis.

However, Linebarger believes that development of facilities generating sustainable electricity can provide the capacity needed to allow hydrogen production. This will be costly, coming with an estimated price tag of US$350 billion for the electricity required to produce hydrogen using green electrolysis technology. And Linebarger said, “We expect green hydrogen to replace grey hydrogen.”

Some industries will switch to using hydrogen as fuel earlier than others and Linebarger said that he believes the steel production industry, a major user of energy, will be one of the first. Looking ahead, Linebarger said, “The cost of green hydrogen will reduce.” And he claimed, “Cummins will lead in low carbon technologies, just as we do in diesel today.”

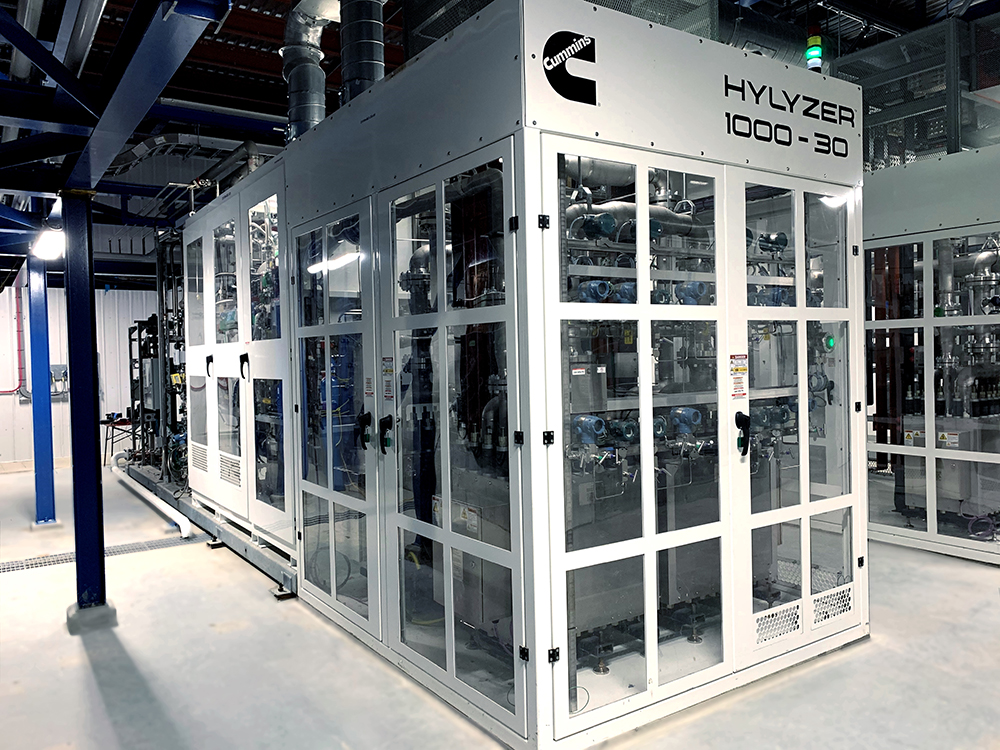

To produce the necessary hydrogen will require a major investment in electrolysers and demand for this technology will be strong. Amy Adams is vice president, fuel cells, at Cummins and said that that the firm has now broadened its operations with the acquisition of proven technologies for electrolysis. These include smaller and more compact proto exchange membrane (PEM) types for mobile installations, and larger solid oxide (SOE) types for high-volume, static production.

The firm’s PEM systems are rugged and can cope with a wide range of operating temperatures. These offer good power to weight ratios, while they can be operated in parallel for high-output applications and deliver efficiencies of up to 60% (compared with 50% for the best diesels). These characteristics suit the versatile and mobile PEM systems to installations in mobile equipment, according to Adams. The company’s SOE systems suit static installations but can deliver efficiencies as high as 80% meanwhile.

Prototype fuel cell power systems are in use on mobile equipment around the world, with trains, trucks and buses being trialled in various countries, said Adams.

Thad Ewald is vice president of corporate strategy at Cummins and said that, at present, most electrical power is not generated using sustainable means. But he added that the cost of renewable power generation is dropping rapidly, which will be crucial to the growth of hydrogen as a fuel. Similarly, distribution costs for hydrogen as a fuel will drop.

Amy Davis is vice president at Cummins, and president of New Power. She said that the firm is presently installing the world’s largest SOE electrolyser plant in Canada, which will be able to produce 300,000tonnes/year of hydrogen. Meanwhile, even larger facilities are in planning. According to Davis, most of the hydrogen currently produced around the world is directed towards the production of fertilisers.

The fuel cell technology for mobile machines is already well-proven and Davis thinks that by 2030, up to 10% of trains and 10% of buses could have already switched over to using hydrogen as fuel. She added that for trucks and off-highway machines, this transition process will take longer.

Replacing diesel with hydrogen as fuel will need a massive global increase in sustainable electricity generating capacity. Solar panels in arid areas in North Africa, the Middle East or parts of Latin America, or wind and hydroelectric stations in Europe and China could deliver the necessary capacity. Linebarger commented, “We know the adoption of sustainable power will take time.”