Looking to the future, the company is working on a diverse array of technologies for hydrogen and fuel cell technology, which will play a key role in the decarbonisation of plant and equipment.

To make mass-market hydrogen powertrains a reality, Cummins is focusing its efforts on the application of hydrogen in engines and fuel cells, the production of green hydrogen (produced by renewable energy), as well as the management and transportation of the fuel.

Cummins has several ongoing projects related to these development areas, with over 2,000 fuel cell installations in various on- and off-highway applications. These include commercial truck operations in Norway with ASKO, a major grocery wholesaler in the region, and Alstom’s Coradia iLint – the world's first hydrogen-powered train in commercial operation throughout Europe.

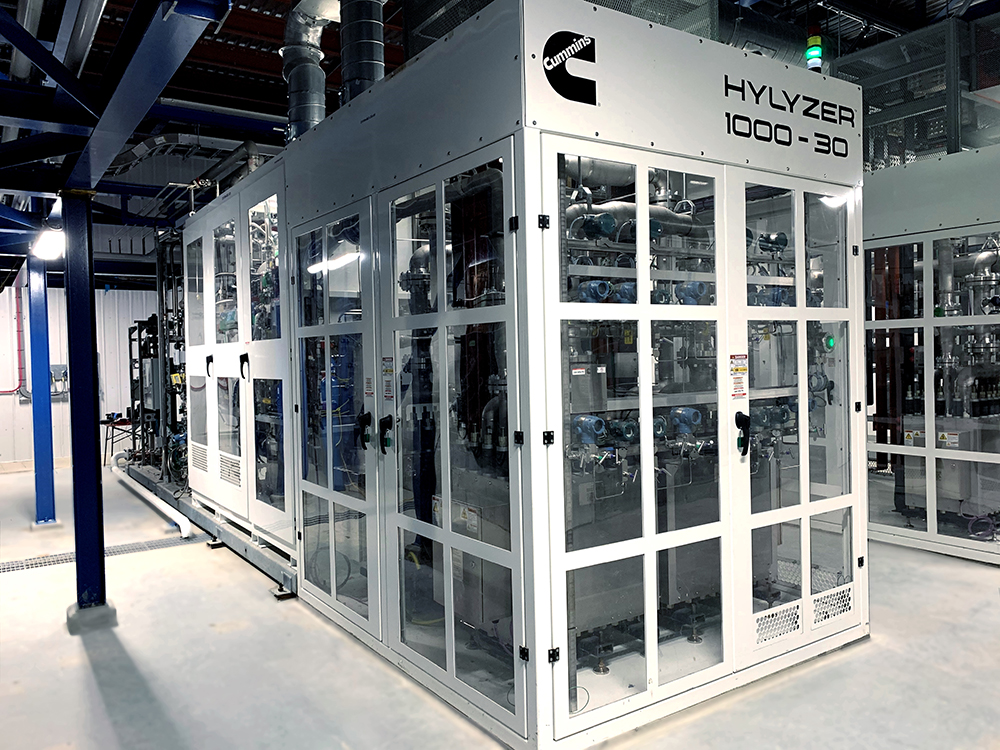

Recent developments from Cummins include its announcement that alongside Air Liquide, the partners completed construction and commissioning of the world’s largest proton exchange membrane (PEM) electrolyser, which is used to generate hydrogen. The PEM is powered by renewable energy and is producing up to 8.2tonnes/day of low-carbon hydrogen in Bécancour, Québec.

In 2021, Cummins announced a partnership with Iberdrola, to build one of the world’s largest electrolyser plants in Castilla-La Mancha, Spain for green hydrogen production. A joint venture with NPROXX also means Cummins is building capability in high-pressure hydrogen storage for stationary and mobile applications.

Jeremy Harsin, Cummins Off-Highway Business Director said, “Looking forward, we see battery electric and hydrogen as complementary technology, part of a suite of zero-emission powertrains, as there is no one-size-fits-all-universal solution for all vehicles, plant and equipment.

“Full-electric is more suited to compact equipment, such as mini-excavators, particularly those used in rental. Hydrogen makes sense for larger equipment such as excavators and road planers, as their high energy demands would require unpractically and uneconomically large batteries. The long recharging times and charging infrastructure required by such equipment is also a deterrent. For heavier duty cycles, hydrogen engines or fuel cells would offer more flexibility and higher machine utilisation. They are well suited for heavy loads and long work shifts with quick refuelling and no CO2 emissions,” explained Harsin.

“The integration of and interaction between hydrogen fuel cells or engines, batteries, powertrain, and fuel storage will be critical to their success. Understanding and adapting the overall powertrain system will be crucial to achieve it. To prepare for this we have recently announced the opening of our Hydrogen Fuel Cell Powertrain Integration Center in California, USA.”

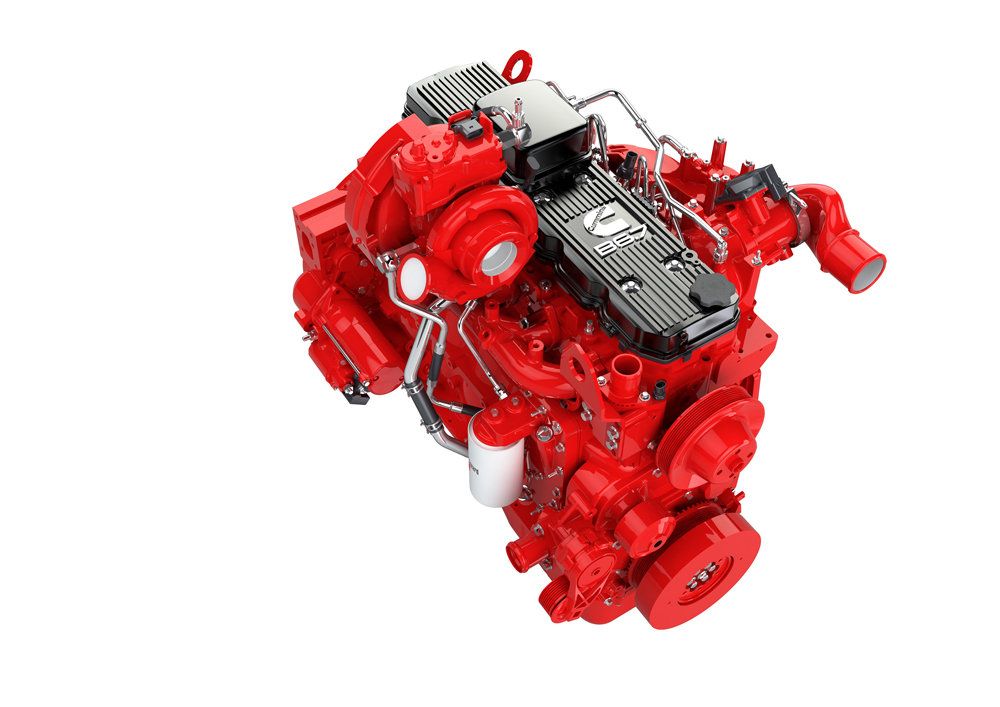

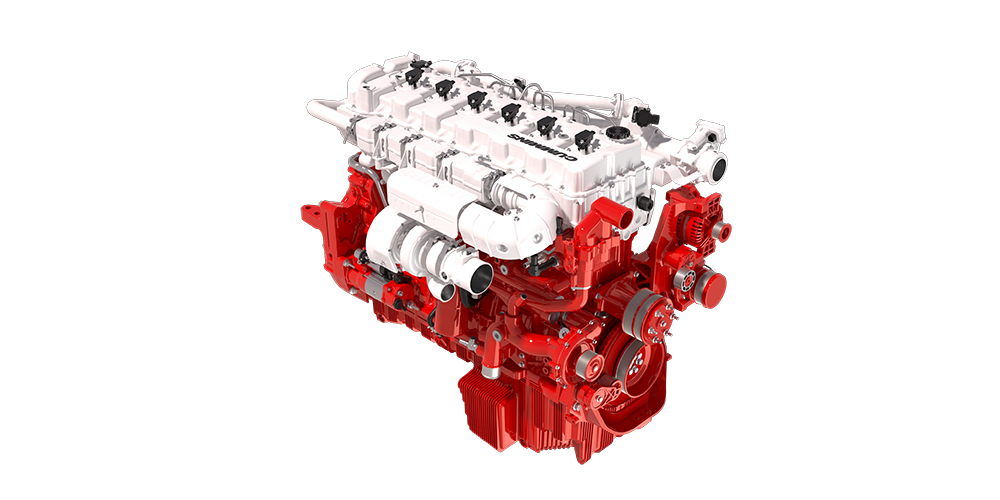

“We are also developing engines capable of running on hydrogen. Following an award from the UK Government we are working on 15litre and 6.7litre platforms which will provide a sustainable solution that is more aligned with current machine designs, reducing complexity for OEMs,” said Harsin.