Driveline specialist Dana is developing a full connectivity suite for its transmissions, axles and other driveline components.

The Dana Spicer Smart Suite collects, manages, analyses, communicates and acts on data from the complete drivetrain, including load and condition monitoring, torque management, speed sensing and steering sensing. This provides critical alerts and allows the operator to react to operational changes, boosting productivity and safety.

“As the construction market becomes more comp

ZF’s innovative new drivelines can cut fuel consumption

World Highways looks at some of the latest drivetrain and component advances – David Arminas reports

The name of the game this year for manufacturers is improved efficiencies when it comes to new drivetrain systems and fluids.

7292 Comer Industries is developing its integrated power transmissions solutions to boost productivity and efficiency for original equipment manufacturers. The company is adding the S-46 Hydro axle to its line-up for compact wheeled loaders. The axle now benefits from a hydrostatic radial motor mounted in line with the input shaft, permitting four-wheel drive connection with reduced installation space.

Comer is also launching a complete driveline system for soil compactors, the first one being installed on a machine from162 Atlas Weyhausen. The driveline consists of an F-128 axle with PG-161 planetary drive for the rear axle and a wheel drive unit for the compaction drum.

Also new to the line-up is a PGR-3600 rotating housing drive available for both wheeled and tracked machines. The PGR-3600 series offers higher torque outputs and load capacities than previous models, with Comer claiming increased reliability.

Comer claims that the PGR-3600 drive is much lighter and less bulky than its competitors’ ranges, as specific and deepened FEM analysis were run during the design phase, followed by bench and field- test endurance validation.

Its internal design and flexible layout make the new PGR-3600 series the right choice for a wider range of mobile equipment either as wheel or track drive but also suitable as winch drive for cranes or fixed machinery. By coupling the PGRF-3603 to a Comer Industries’ differential axle, the company is able to provide a complete transmission package for soil compactors up to 15tonnes.

By introducing the new PGR-3600 and the upcoming PGR-2500 and PGR-4800 in the next months, Comer Industries says it will have accomplished the remodelling and completion of the PGR series product range, available up to 110,000Nm output torque.

2254 Dana is developing a full connectivity suite for its transmissions, axles and other driveline components.

The Dana Spicer Smart Suite collects, manages, analyses, communicates and acts on data from the complete drivetrain, including load and condition monitoring, torque management, speed sensing and steering sensing. This provides critical alerts and allows the operator to react to operational changes, boosting productivity and safety.

"As the construction market becomes more competitive, equipment manufacturers and owners are pressed to drive greater efficiencies,” said Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

“Dana is actively developing a wide selection of leading edge technologies, led by Spicer Smart Suite technology, that can transform passive drivetrain components into intelligent powerful forces for boosting performance.”

The first application of the technology is an intelligent load monitoring system (ILMS) for telehandlers. While traditional load monitoring collects measurements from a single remote-mounted or retrofit load cell on the rear axle, Spicer ILMS uses data from across the machine to prevent tip-overs more effectively, both when stationary and when the machine is mobile.

7645 Dynavis, a major additive product from 4009 Evonik, helps fine-tune engines, pumps, drive systems and hydraulics.

“A simple change of hydraulic fluid can help save fuel, even –and particularly– in used construction machines,” said Rolf Fianke, technology aftermarket support manager at Evonik.

In Italy, Nuova Ghizzoni, an Italian pipeline contractor, switched its entire fleet of hydraulic excavators to a fluid formulated with Dynavis technology supplied by a Dynavis licensee. The switch was a move away from conventional single-grade and multi-grade oils.

Evonik says it has also teamed up with several global partners, including the French mineral oil multinational Total, Indian energy giant Indian Oil Corporation, American lubricant specialists such as Schaeffer Oil and Hermann Bantleon, a German producer of lubricants. Common to all these lubricant marketers is goal of more market share in the high-end hydraulic fluids sector.

The Dynavis brand doesn’t represent a hydraulic fluid, but rather a technology, and a complete package of formulation support and global services, using an additive that improves the viscosity index of hydraulic fluids. Evonik claims that fuel savings of up to 10% are achievable, with up to 30% under extreme loads.

7296 Mitas is launching its first ever tyre for rigid dump trucks – the ERD-45 18.00R33. The tyre’s tread pattern is designed for hard surface conditions and is said to have excellent traction. ERD-45 has a sidewall protection and it is also highly resistant to cuts. Three further s ERD-45 tyres – the 21.00R33, 21.00R35 and 24.00R35 – will be unveiled by Mitas during 2017-18. The new ERD-45 tread pattern in Mitas’ Earthmover tyres portfolio will take its place alongside the ERD-20, ERD-30 and ERD-40 tyre tread patterns.

7214 Oerlikon, Fairfield and Oerlikon Graziano are keen to demonstrate a range of high-tech driveline solutions to OEMs.

Oerlikon Fairfield in particular is working on a range of modular hybrid technologies, with motors integrated into the gearbox that could be used to drive compact tracked loaders and other small machinery. Oerlikon Graziano is focussing on shifting solutions, with new hydraulic powershift clutch modules on offer to deliver improved driver comfort and reduced component wear.

In both cases the company is keen to deliver complete driveline solutions for OEMs, offering everything up to the back of the engine. This includes a new family of torque hubs and wheel drives with integrated hydraulic motors. Oerlikon currently has two dedicated hybrid drivelines in test with manufacturers.

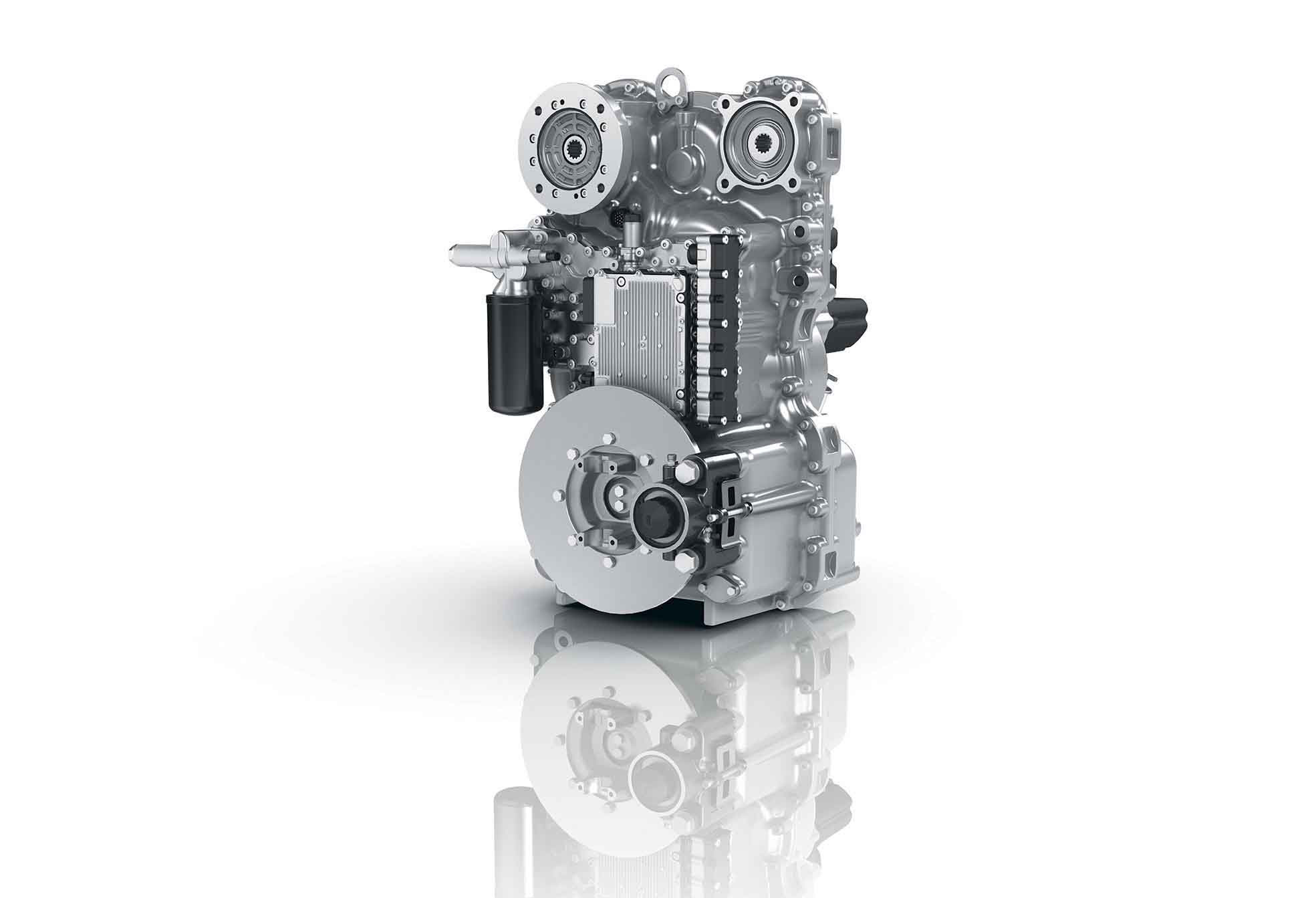

2304 ZF will focus on efficiency and reducing fuel consumption at this year’s bauma construction equipment exhibition in Munich, Gemany, this month.

The transmission and driveline component manufacturer will present its Ergopower efficiency package that combines the cPower continuously variable transmission with the ZF Hybrid module that should be commercially available in the future. cPower is a hydromechanical variable transmission that combines hydrostatic drive pumps with a mechanical powershift gearbox.

Available for use in a range of machines, including wheeled loaders, telehandlers, graders and wheeled excavators, ZF claims that HVT can save up to 25% in fuel costs. The firm’s hybrid system will be able to be used with all forms of ZF transmission and could be incorporated in the transmission or separately in the machine for additional fuel consumption benefits.

The name of the game this year for manufacturers is improved efficiencies when it comes to new drivetrain systems and fluids.

Comer is also launching a complete driveline system for soil compactors, the first one being installed on a machine from

Also new to the line-up is a PGR-3600 rotating housing drive available for both wheeled and tracked machines. The PGR-3600 series offers higher torque outputs and load capacities than previous models, with Comer claiming increased reliability.

Comer claims that the PGR-3600 drive is much lighter and less bulky than its competitors’ ranges, as specific and deepened FEM analysis were run during the design phase, followed by bench and field- test endurance validation.

Its internal design and flexible layout make the new PGR-3600 series the right choice for a wider range of mobile equipment either as wheel or track drive but also suitable as winch drive for cranes or fixed machinery. By coupling the PGRF-3603 to a Comer Industries’ differential axle, the company is able to provide a complete transmission package for soil compactors up to 15tonnes.

By introducing the new PGR-3600 and the upcoming PGR-2500 and PGR-4800 in the next months, Comer Industries says it will have accomplished the remodelling and completion of the PGR series product range, available up to 110,000Nm output torque.

Dana’s smart controls

Driveline specialistThe Dana Spicer Smart Suite collects, manages, analyses, communicates and acts on data from the complete drivetrain, including load and condition monitoring, torque management, speed sensing and steering sensing. This provides critical alerts and allows the operator to react to operational changes, boosting productivity and safety.

"As the construction market becomes more competitive, equipment manufacturers and owners are pressed to drive greater efficiencies,” said Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

“Dana is actively developing a wide selection of leading edge technologies, led by Spicer Smart Suite technology, that can transform passive drivetrain components into intelligent powerful forces for boosting performance.”

The first application of the technology is an intelligent load monitoring system (ILMS) for telehandlers. While traditional load monitoring collects measurements from a single remote-mounted or retrofit load cell on the rear axle, Spicer ILMS uses data from across the machine to prevent tip-overs more effectively, both when stationary and when the machine is mobile.

Dynavis helps save fuel

“A simple change of hydraulic fluid can help save fuel, even –and particularly– in used construction machines,” said Rolf Fianke, technology aftermarket support manager at Evonik.

In Italy, Nuova Ghizzoni, an Italian pipeline contractor, switched its entire fleet of hydraulic excavators to a fluid formulated with Dynavis technology supplied by a Dynavis licensee. The switch was a move away from conventional single-grade and multi-grade oils.

Evonik says it has also teamed up with several global partners, including the French mineral oil multinational Total, Indian energy giant Indian Oil Corporation, American lubricant specialists such as Schaeffer Oil and Hermann Bantleon, a German producer of lubricants. Common to all these lubricant marketers is goal of more market share in the high-end hydraulic fluids sector.

The Dynavis brand doesn’t represent a hydraulic fluid, but rather a technology, and a complete package of formulation support and global services, using an additive that improves the viscosity index of hydraulic fluids. Evonik claims that fuel savings of up to 10% are achievable, with up to 30% under extreme loads.

Mitas truck tyre

Oerlikon’s high-tech systems

Oerlikon Fairfield in particular is working on a range of modular hybrid technologies, with motors integrated into the gearbox that could be used to drive compact tracked loaders and other small machinery. Oerlikon Graziano is focussing on shifting solutions, with new hydraulic powershift clutch modules on offer to deliver improved driver comfort and reduced component wear.

In both cases the company is keen to deliver complete driveline solutions for OEMs, offering everything up to the back of the engine. This includes a new family of torque hubs and wheel drives with integrated hydraulic motors. Oerlikon currently has two dedicated hybrid drivelines in test with manufacturers.

ZF’s innovative transmission

The transmission and driveline component manufacturer will present its Ergopower efficiency package that combines the cPower continuously variable transmission with the ZF Hybrid module that should be commercially available in the future. cPower is a hydromechanical variable transmission that combines hydrostatic drive pumps with a mechanical powershift gearbox.

Available for use in a range of machines, including wheeled loaders, telehandlers, graders and wheeled excavators, ZF claims that HVT can save up to 25% in fuel costs. The firm’s hybrid system will be able to be used with all forms of ZF transmission and could be incorporated in the transmission or separately in the machine for additional fuel consumption benefits.