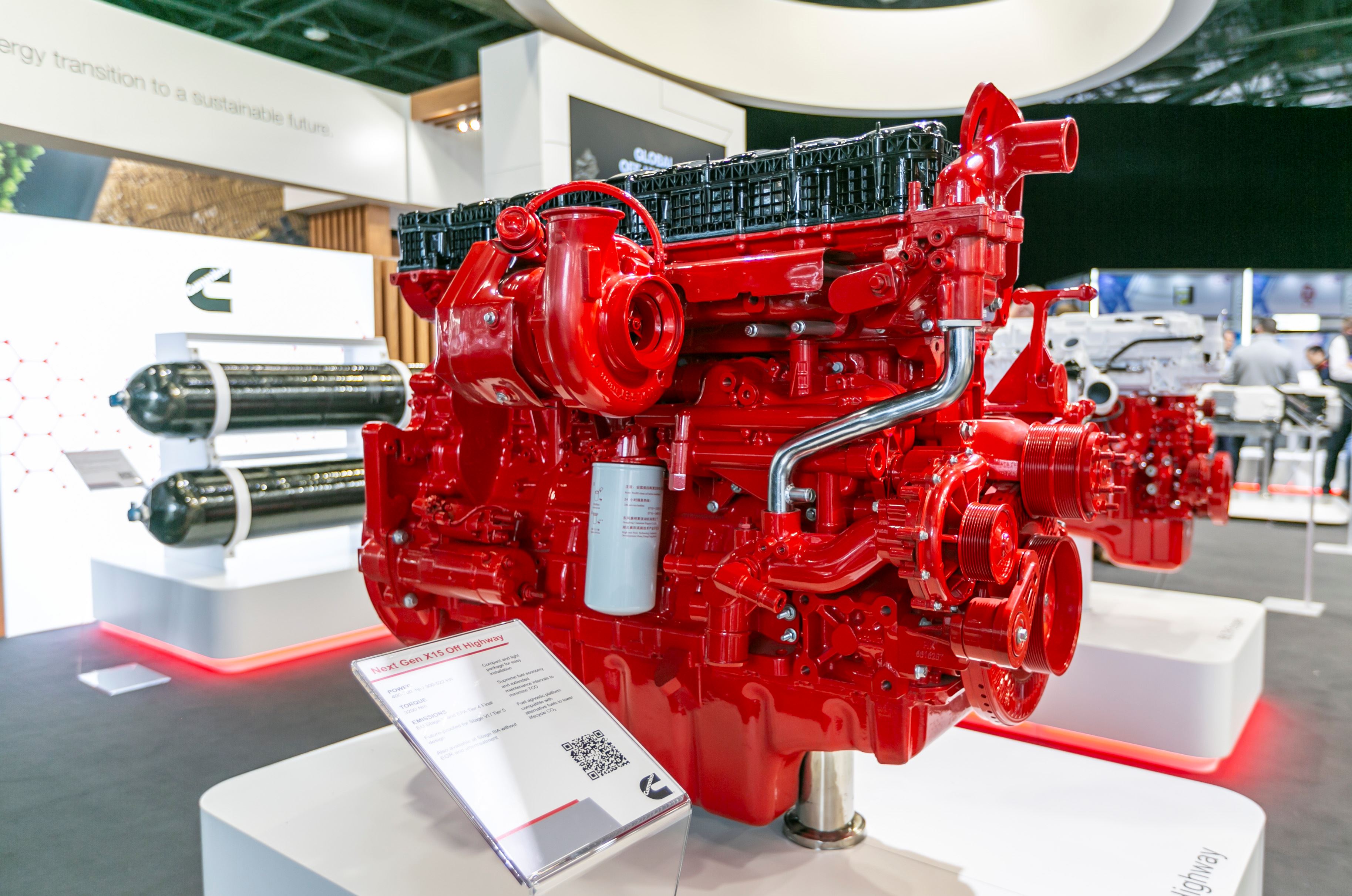

Cummins is expanding its range of fuel-agnostic engines further with the introduction of its new X15 unit. The firm says that this advanced 15litre engine offers reliability and lower operating costs as well as reduced emissions and improved fuel efficiency.

The engine is part of the Cummins HELM platform and offers customers the option to choose the fuel that best suits their needs. The common base can have cylinder heads and fuel systems specifically tailored for a single fuel- advanced diesel, natural gas or hydrogen.

The X15 for Off Highway offers ratings up to 522kW and a peak torque of 3200Nm, meeting Stage V emissions and stricter requirements to come. The X15 engine offers fuel consumption as low as 180g/kWh, reducing TCO and lifetime CO2 emissions. It has extended maintenance intervals up to 1,000 hours, reducing service costs and downtime.

Meanwhile, Deutz is also introducing an engine that will run on hydrogen as well as electric power retrofit options for off-highway machines. These form part of the firm’s programme aimed at reducing carbon emissions.

The programme represents a substantial investment in research and development for Deutz. “We are investing €100 million until the end of next year,” says Bert van Hasselt, head of sales and service for Deutz’s BU Green division.

Deutz units for China

The new hydrogen engine being tested is the TCG7.8H2 unit, a 7.8litre engine that will deliver 228kW. The first production units will be manufactured in the third quarter of this year and be aimed initially at genset or rail applications, with an order for 100 units being supplied to China. However, once the units have been proven in these applications further duties will be available, including installations into construction machines.

According to van Hasselt, the continuing high price of hydrogen as a fuel means that the unit sales will remain low until a better hydrogen supply infrastructure - and more reasonable fuel prices - become available.

In the meantime, Deutz believes its electrification retrofit package will be of interest for customers with equipment that is comparatively new. These can be tailored to a wide range of equipment applications. “We can retrofit equipment with diesel engines with an electric system. It’s part of the transition into the new world,” said van Hasselt.

To further expand the electrification range, Deutz is offering its onsite PowerTree package that provided electric power onsite with ratings from 30kW/h up to 2MW/h.

However, Deutz still believes there is demand for conventional diesels and is introducing the TCD2.9, a 2.9litre engine which meets Stage 5/Tier 4 Final emissions requirements. It has been developed jointly with John Deere. Coming later will be the TCD3.9 unit, also developed jointly with John Deere. It will enter field test mid this year and offering ratings from 75-130kW.

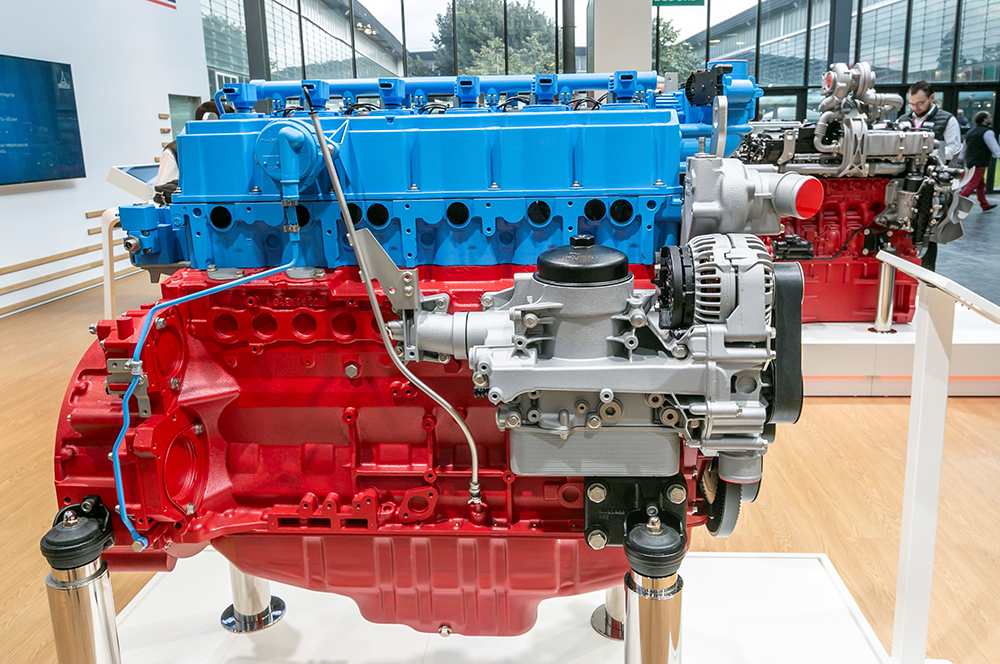

Volvo Penta is also offering a new fuel-agnostic engine with its D17 unit, which takes over from the D16 as the firm’s top-of-the-range products. Compared to the D16 model, the new D17 offers up to 5% less fuel consumption due to developments in combustion technology, such as the common-rail fuel-injection system.

Volvo Penta is investigating alternative fuels and various technologies and all Volvo Penta engines can run on hydro-treated vegetable oil (HVO). The D17, together with the rest of the Volvo Penta power generation line-up, will be developed to allow customers to transition to lower well-to-wheel emissions using renewable fuels, according to the firm.

The new cooling package has the option of a viscous fan and air-filter to suit a variety of installations and further reduce fuel consumption and noise emissions. Power density is high and the 17litre engine uses dual-stage turbochargers and heavy-duty steel pistons. It has a compact and low-weight design said to offer smooth operation with low noise and vibration and an overall easy installation, service and transport.

The D17’s sister engine, the D16, has an inline six-cylinder block and provided the starting block for the new design, ensuring the D17’s basic footprint would remain the same.

Electric option

Moog Construction is offering the novel electrification retrofit kit from subsidiary Zquip for repowering machines in the construction, rental and quarry markets. This modular system can be installed in machines such as excavators and wheeled loaders in the 5-50tonne range and from any manufacturer.

The company is also offering its modular batteries as a suitable solution for onsite power at remote locations.

Scott Scheffler, marketing director of ZQuip says that repowering existing machines provides a suitable solution for some customers. “We’re trying to make it easy for people to get into electrification in a more cost-effective way. With our solution, the batteries are swappable and fast charging. The machine hydraulics do not change at all.”

The package consists of ZQuip batteries, an electric motor, a smart controller and a thermal unit to optimise battery temperature. Customers select either 70kW/h batteries or 140kW/h batteries. These have the same footprint to ease installation and use the same base, although the 70kW/h units are shorter and weigh 700kg while the 140kW/h units are taller and weigh 1,250kg. Depending on installation and machine type, customers select the optimum number of batteries.

Fast recharging allows recharging within one hour and the system comes with standard plugs and connectors. Batteries can be exchanged in only five minutes using a forklift truck or a handling machine if more power is needed for the machine to keep on working. Rental firms can leave machines onsite and deliver freshly charged batteries if required or customers can use a charging station at the worksite. The smart controller draws power from one battery at a time and a display in the machine cab shows how much charge remains.

“You’re able to keep machines running all day either by exchanging batteries or recharging,” says Scheffler. “We’re making it easy for customers to adopt electrification.”

The system can be used in a wide array of applications and is of benefit to firms running mixed fleets of machines as it allows them to use the same modular battery technology. The power units can be exchanged between different pieces of equipment. According to the firm, the system is already accepted by equipment dealers and comes with warranties.

Meanwhile, the remote power solution allows rental firms to deliver the batteries to customers for operating site office lighting, computers, heating or air conditioning. The rental firm will be able to monitor power levels remotely and deliver freshly charged batteries when needed. Customers can choose from 70kW or 140kW batteries and these use a common base unit.

The package also includes a smart controller, thermal kit and energy management app to provide an intelligent energy module, according to the company.