A recent HMRC clampdown on UK trommel fines is said to have led to sky-high demand for Dig A Crusher’s Max X Tract Density Separator. Despite being part of the Dig A Crusher product line for the past few years, last year saw only 11 models delivered to customers. Although their use was pioneered by forward-thinking recycling companies keen to extract every ounce of value from their waste streams, the vast majority of firms were content with paying the £2.50 Landfill Tax imposed on the trommel waste fines th

A recent HMRC clampdown on UK trommel fines is said to have led to sky-high demand for Dig A Crusher’s Max X Tract Density Separator.

Despite being part of theHowever, within 24 hours of the launch of the HMRC fine clampdown on Friday, May 18, Dig A Crusher managing director Sean Heron received three confirmed orders for the Density Separators, marking the start of the machine’s popularity.

“On 18 May, HM Revenue & Customs issued a brief that said that waste fines that had previously been covered by the lower £2.50/tonne Landfill Tax rate would be charged at the full £64/tonne rate with immediate effect. This left waste management, demolition and recycling companies staring down the barrel of a huge hike in their waste disposal costs,” Heron says. “Overnight, we went from offering a very good, low-volume, niche machine to having the low-cost solution to a 2,500% disposal rate increase.”

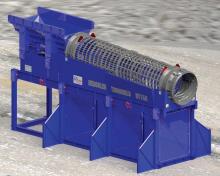

The Max X Tract Density Separator is designed to segregate stone, lights, wood ferrous and non ferrous materials from -100mm materials, enhancing materials resource efficiency and minimising the levels of material sent to landfill. Weighing just nine tonnes and fully self-contained, the compact yet durable machine is said to be easily incorporated into existing waste handling and extraction streams, allowing users to extract potentially valuable recyclable materials to generate additional revenue and minimise waste disposal by up to 90%. It is capable of processing up to 150tonnes/hour.