Innovations in drilling and blasting and crushing and screening are bringing major economies of scale to aggregate production operations. Drilling and blasting is an area where new technology is offering major saving to quarrying companies. This is another important factor in the quarrying process, as inefficient drilling and blasting can have major financial repercussions.

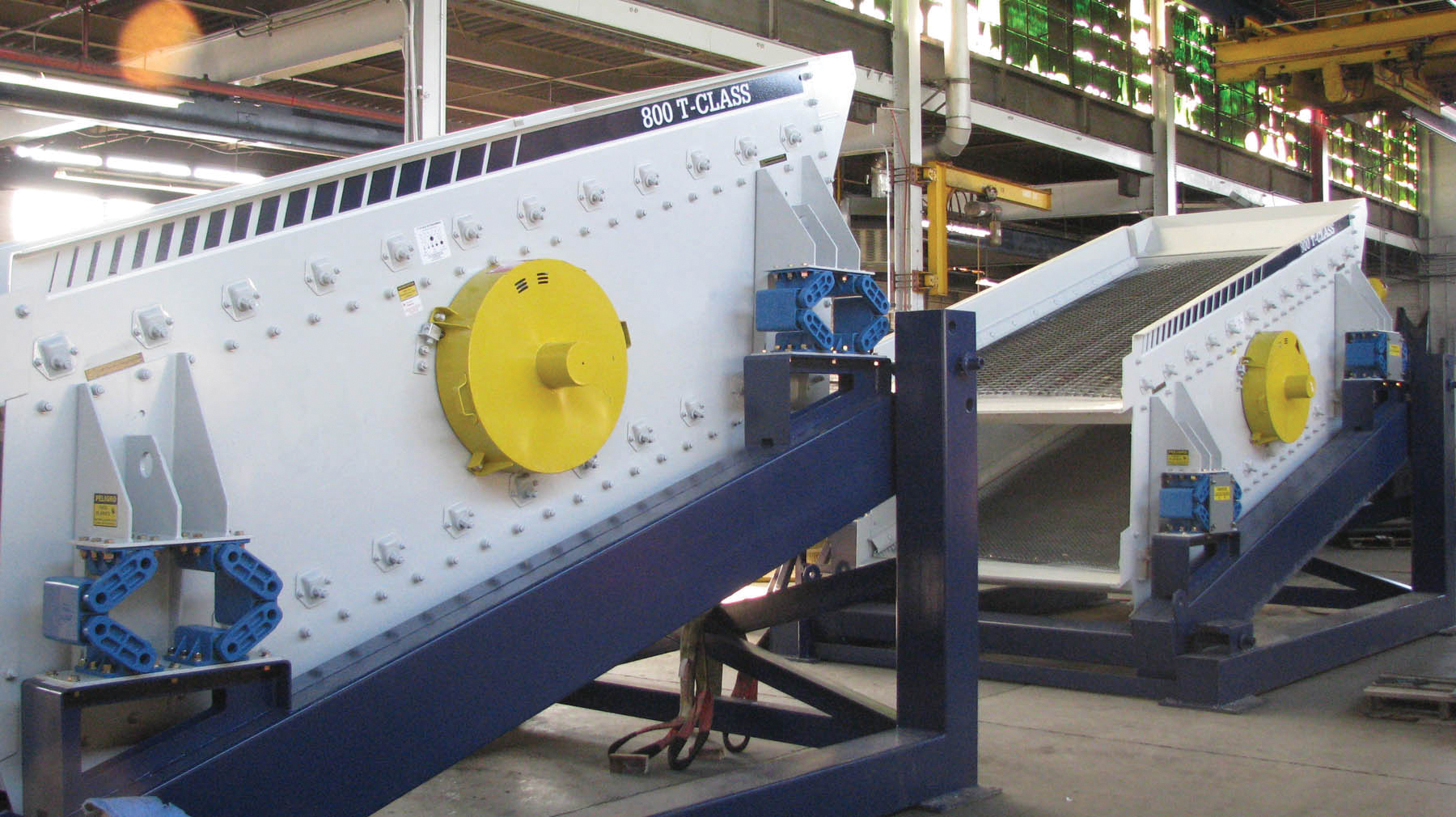

WS Tyler offers an array of proven screening solutions, with the range being strengthened due to the deal with Major Wire Industries

Efficient throughput is a key to effective quarrying operations - Mike Woof reports

Innovations in drilling and blasting and crushing and screening are bringing major economies of scale to aggregate production operations.Drilling and blasting is an area where new technology is offering major saving to quarrying companies. This is another important factor in the quarrying process, as inefficient drilling and blasting can have major financial repercussions. Inefficient blasting can leave an uneven quarry floor that results in wear and tear on loading machines, increased wastage through excessive fines generation and also increased need for costly secondary breaking. Straighter blastholes are crucial and

According to the firm the GT60 drilling tool and tube system is designed to optimise the transfer of impact power from drill rigs such as Sandvik’s DP1100 and DP1500. However the system is also compatible with the typical piston size and power of other drills with similar performance. The new thread design and tailored drill steel dimensions are matched to transform impact power into efficient rock-breaking. This also helps boost service life for the entire drilling system.

The new Uniface design features an innovative, patented face design, that combines the former flat face and drop centre. Compared with traditional designs this new Uniface offers better rock drilling, more efficient flushing and improved distribution of energy in order to penetrate the rock. Combined with the GT60 tube system, this reduces unscheduled stoppages, boosts productivity and cuts bit costs. The GT60 tube system also ensures better hole straightness, high penetration rates and long service life. Sandvik Uniface bits with ballistic buttons are now available from 51-115mm to suit Sandvik extension rods R32, T35, T38, T45, T51 and GT60.

Meanwhile an array of new technologies are coming to market, to smooth flow through crushing and screening operations, as well as reducing downtime. Sophisticated machine and process management systems are also ensuring throughput is more steady, while products are more consistent, delivering major returns on investment for quarry companies.

Part of the

All study, design and management phases have been followed by Raffaele Piludu, technical manager of the Calcestruzzi crushing plants for central and southern Italy. After looking at various alternatives, Piludu opted for the package from Ma-estro as this best matched the parameters of the operation. The supplier presented a complete package, supplying a real-time management program along with automated plant control.

The plant comprises a line for primary washing and selection of natural sands and another line for crushing, washing and selection of gravels with production of crushed sand. The system manages both production lines, which it displays on two monitors and all of the graphics have been customised to make the system intuitive.

Using the Ma-estro quarry control system, the entire plant can be run with a relatively small number of staff, an objective intended to save money for the producer as well as increase safety on site. Using the system has cut the number of personnel required at the facility as all material controls and dosing can be managed automatically.

The quarry control package is said to be a versatile system that allows fast electronic communications between the various modules made available, especially on this plant. The quarry production control package is able to manage processing times and energy consumption, including routine and extraordinary maintenance and quality control. The package also optimises production by automating the plant start/stop sequences and checking all working machines.

The hardware installed in this package includes weighing systems for production control, monitoring of electrical power used, sonar type level sensors and a hydrocyclone pressure control. It also includes control of current flow for all machines, rotation sensors on all belts, jamming sensors, washing water level sensors and control via and inverter for all feeders.

The quarry control pro system is the software that automates the production process. The system detects the load of the machines present on the plant and determines the material that the plant must produce to reach maximum efficiency. This technology has been calibrated for the plant as these can vary widely depending on an array of parameters.

As well as the automatic regulation of the aggregates flow rate, the system monitors belts and possible jamming points, which could lead to plant downtime and contamination of the material produced. In terms of efficiency, the system boosts performance for a wide array of material, adapting itself to all situations in real time, both in the presence of coarse and sandy material. This allows the plant always to be calibrated specifically on the basis of the material type. Operating parameters are protected by password and can all be modified by the plant administrator.

Business changes are coming too to the crushing and screening sector. German firm Haver & Boecker, owner of Ontario-based

W.S. Tyler has acquired a 40% share of Major Wire Industries and will purchase the remaining 60% in 2016 under the terms of the deal. W.S. Tyler management has asked Major Wire to manage its Salisbury woven wire facility with the intent to serve Major Wire’s extensive dealer network throughout the US and in Latin America. All remaining operations for both companies within North America and globally will continue to operate independently. W.S. Tyler and Major Wire dealers and representatives throughout the world will also continue serving their respective customers and prospects as they do today.

“Our alliance with Major Wire will be an opportunity for two family-owned manufacturers to employ their combined strengths and expertise to the benefit of the North American and global markets,” commented Walter Haver, joint owner of Haver & Boecker. “It is clearly a win-win for all personnel, sales channels, vendors and most of all, the customers we serve.”

Jean Leblond, president and owner of Major Wire Industries explained that he has found a partner that shares the same values, desire to invest in the future and focuses on the customer first.

Since being purchased by Haver & Boecker in 1997, W.S. Tyler has introduced a new wave of innovation in screening technology. Major Wire is a leading manufacturer of innovative screen media, including Flex-Mat 3 Tensioned and Modular and OptimumWire Woven Wire.

The smallest of the

Ready pumps handle flows up to 7litres/second, heads to 14m and have power ratings range from 0.5-0.82kW. Weighing only 12kg and 14.5kg respectively, Ready 4 and 8 are designed for dewatering of construction sites, flood cleaning operations and similar applications. They can handle abrasive and corrosive liquids and particle sizes up to 5mm. The Ready 8S is a solids-handling pump designed for contaminated water and water containing sand, gravel and debris with particle sizes up to 38mm.