A wide range of new machines are now coming to market for the crushing and screening segment. These offer better throughput as well as improved product quality. Meeting sustainability targets is also crucial for future operations, with manufacturers now looking more often to electric solutions for their equipment for example. In addition, issues such as mobility and maximising uptime through the use of smart telematics systems remain of high importance for the segment.

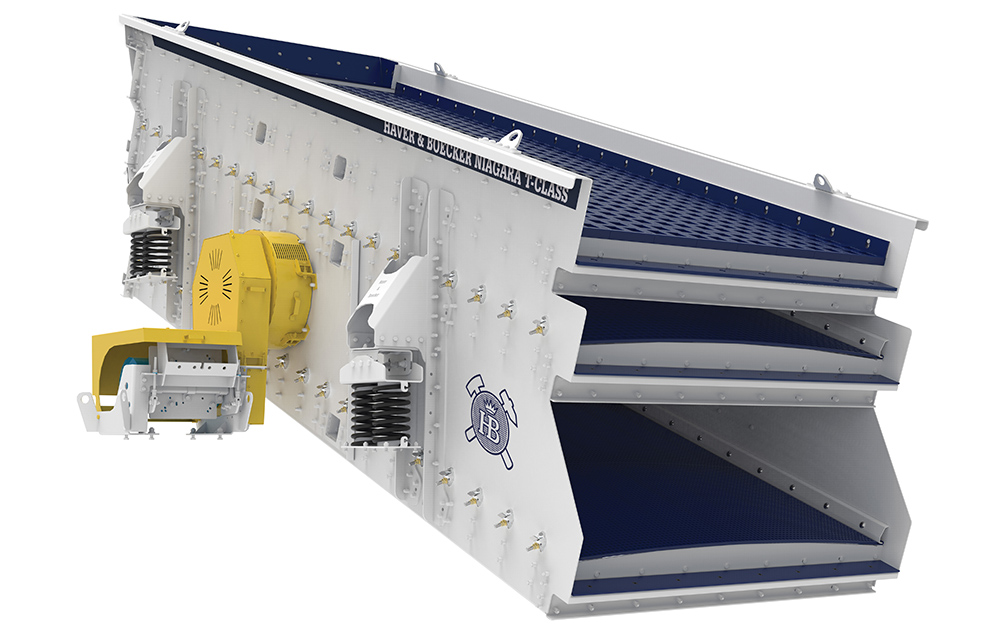

Haver & Boecker Niagara says that its next-generation Niagara T-Class vibrating screen retains the benefits of the concentric technology while improving screening uptime and performance with new features. The T-Class provides producers with a cost-effective, maintenance-friendly solution to process a wide range of materials.

The T-Class deck frame is now primarily lockbolted rather than welded to provide optimum strength, reliability and safety. Lockbolts are proven to be more effective than welding in the demanding, load-bearing, high-vibration operation of a vibrating screen to ensure the machine’s structural integrity.

The new design allows producers to upgrade their vibrating screen with the new Drop Guard system, further minimising maintenance. The innovative liners provide 100% cross beam protection, both reducing wear and extending the life of the vibrating screen. The system simply drops over the cross beam with no adhesive or tools required, making installation quick and easy.

Additionally, Haver & Boecker Niagara redesigned the flat deck frames of the new T-Class vibrating screen for simplified maintenance. The pin & anchor deck frame is adaptable to virtually any pin-style modular screen media. It features polyurethane anchors that are easy to replace and prevent premature wear on the deck frame. Additionally, the open design of the modular deck prevents material build-up on the bar rails. The cap & slide deck frame is adaptable to virtually any groove style modular screen media and features full rail protection.

The T-Class can also be manufactured for side-tensioned or bottom deck end-tensioned screen media. Each new side-tensioned machine comes with Haver & Boecker Niagara’s signature Ty-Rail quick-tensioning system, which halves screen change-out times.

One of the key products that Keestrack is launching is the completely redesigned Keestrack I4e tracked mobile reversible impact crusher with an advanced diesel-electric drive.

Thanks to the RIC, or Reversible Impact Crusher, this machine is very flexible in the secondary and tertiary crushing of rock and recycling building materials, for example, asphalt. The specific design of the reversible horizontal impact crusher with a large variable crushing chamber, powerful rotor and electronically monitored hydraulic gap adjustment allows feed sizes of up to 250mm and ensures consistently high-quality end products of up to 0-2mm in closed circuit.

Secondary and tertiary crushing can be now combined in one highly mobile solution, according to Keestrack. This makes the I4e an alternative to mobile cone crushers or vertical impact crushers and offers production capacities from 100-250tonnes/hour.

According to Keestrack, the system means lower wear, better quality of the end products (grain shape) and significant energy savings in typical applications such as sand production.

As with other Keestrack large crushers, the drive unit, with its 447kW diesel engine and 300kVa generator, is designed as a removable drop-off module. Electric drives for the crusher, with 160kW of power, feeders and conveyor belts as well as the system hydraulics, enable particularly cost-efficient and emission-free plug-in network operation.

Meanwhile, Keestrack says that its e-drive equipment can run plugged-in to the grid or can be run by the onboard diesel/genset or by any other generator. The crushers, screens and stackers can all be connected to each other, resulting in bigger savings.

To facilitate this, Keestrack says that its latest M5 tracked engine unit uses a Cummins X12 EU Stage V engine and alternator. It delivers 383kW, 450kVA to drive all electric equipment at 197g/kWh.

The tracked engine – the perfect backup for the ZERO drive machines where there is no source of electricity onsite – is part of Keestrack’s lengthy engine/genset portfolio. A few years ago, Keestrack introduced the first drop-off module, a diesel engine with integrated genset, which can power several e-driven machines. It is placed a few metres from the machine in a less dusty environment and allows easier access for service and maintenance, unlike units that are built into a machine’s chassis.

One step further is the introduction of the tracked engine/generator units. These supply connected Keestrack crushers, screeners and stackers directly with electricity in case there is no plug-in available from the grid.

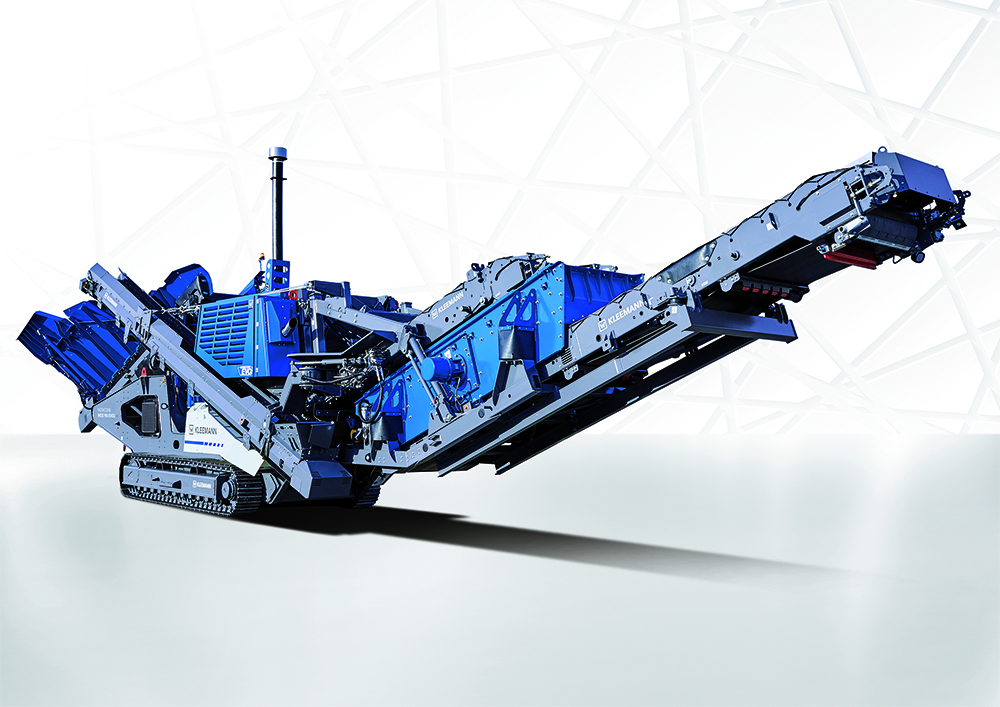

From Kleemann comes the new MOBIREX MR 130(i) PRO impact crusher, which offers versatility, productivity and mobility. This new addition to the firm’s PRO line can be used as a primary and secondary crusher and is said to offer a combination of high output, a quality product and sustainability.

The machine features an all-electric drive concept with the option of an external power supply, offering low energy consumption/tonne of final product. The optional large double-deck secondary screening unit allows the production of two classified final grain sizes.

The MR 130(i) PRO is highly versatile and can be used in a wide application range in natural stone and recycling. With its heavy rotor and powerful electric 250kW drive, the crushing unit is said to deliver a high and stable throughput. A continuous crusher load is guaranteed by the Continuous Feed System (CFS).

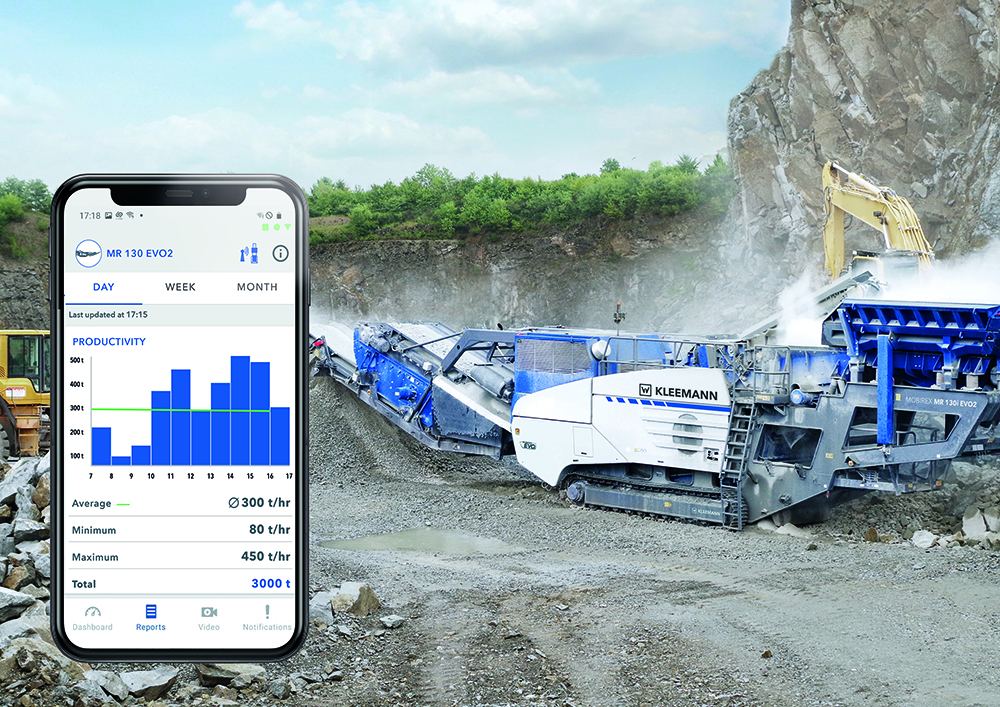

In addition, Kleemann is introducing a new operating concept called SPECTIVE that offers a range of additional functions for users. This sophisticated tool incorporates a touchscreen and radio remote controls and supports work site digitalisation. All relevant process information and reporting can be displayed on the user’s smartphone without having to leave the feeding device. SPECTIVE CONNECT also presents new features, which will make work for the operator easier according to the firm. One of the key features is a new configuration tool that helps the operator select the correct machine settings for each application.

Rubble Master has been powering its mobile processing plants with electricity for decades. Using this expertise, the company says it is continuously setting standards with the energy efficiency and cost-effectiveness of its machines. That is why with the tagline, Meet the future, Rubble Master says it is displaying technology that "is still a dream of the future for others".

With the claimed revolutionary new development of the showcased RM H50X hybrid screen and the RM J110X jaw crusher, customers are said to be saving even more fuel costs. In addition, the RM XSMART software solution and other new digital innovations demonstrate how operators and machines can network intelligently to get even higher output. As a result, mobile RM crushers and screens can be combined in a versatile, flexible and efficient way.

Even before steadily rising fuel prices, the electrification of Rubble Master machines was said by the company to be a "key economic as well as ecological argument".

As part of the RM NEXT philosophy, the RM Group says it is consistently supporting electrification and offers all its crushers and screens as hybrid versions as a matter of principle. These machines can also be operated fully electrically. A special focus is on combining machines to form crushing and screening trains so they can be operated together. This means, for example, that the crusher can also power the screen. That is how customers can save time and money because they only need to refuel and service one engine.

Rubble Master hybrid machines are said by the manufacturer to consume up to 25% less fuel than diesel-direct systems. If a crusher equipped with a hybrid drive system also powers an electric screen - a standard set-up with RM - even greater savings are said to be achievable. With this technology, the savings are said to be much higher than with conventional diesel-hydraulic systems. Another advantage, in addition to lower operating costs, is that the machines can be used in emissions-sensitive areas.

Digital solutions and networked machines increase efficiency in addition to electrification, and Rubble Master is focusing intensively on digitalisation to give customers a full overview of their machines while operating even more efficiently. Using the RM XSMART app, machine operators can network with their machines either using an app on their mobile devices or by using the browser app. Fleet management, condition monitoring, end-to-end reporting and troubleshooting support make everyday life much easier and, at the same time, increase productivity. Rubble Master, however, says it goes one step further by networking the machines with each other. In a networked crushing and screening train, the machines can communicate with each other to adjust their output to optimise the utilisation of the upstream and downstream units or react to an event such as one of the machines in the train switching off. This means that machines are not overloaded, nor do they run idle. Rubble Master says autonomous crushing and screening is the next logical step the group will be presenting soon.

Sandvik Mobile Crushers and Screens claims that its QA452 model is the latest evolution of the Sandvik QA Series products and triple-deck Doublescreen technology. It claims that its Doublescreen technology can outperform conventional screens by up to 30%.

The firm says it has engineered an innovative three-deck tracked mobile plant with independent screen angle adjustment and hydraulic screen separation, patent-pending. It features two triple-deck inline screen boxes with equal size screen decks, each providing 9m3 of screening area.

Screen improvements include an 11% longer bottom screen deck to extract more fines. Featuring independent screen angle adjustment, the primary screen can be independently adjusted from the secondary screen, allowing operators to optimise throughput, screening efficiency, and product gradations.

The primary screen performs as a fines extractor, whilst the secondary screen performs as a grader; two processes on one plant, offering versatility, efficient separation, accurate grading and high throughput.

Sandvik offer the hybrid ‘e’ drive with electric plug-in which allows a user to choose the most economical and efficient energy source.

The QA452 provides a lower environmental impact due to reduced fuel consumption and the latest onboard powerpack offers reduced operating noise and emissions. In addition, the hydraulic system has been enhanced to reduce energy wastage and its hydraulic oil change intervals have been extended from 2000-4000 hours, meaning up to 50% less hydraulic oil is consumed over 10,000 hours of machine usage (subject to oil sampling).

The primary screen can also be hydraulically separated to gain better access for maintenance and screen media changes.

The addition of a new oversize cross conveyor means greater oversize material extraction. This cross conveyor can be reversed, to allow the plant to function like a two-deck screen with oversize and mid overs discharged together.

Each screen deck features end-tension screen media using Sandvik’s novel mesh tensioning system. This means faster screen mesh tensioning and removal and helps boost uptime. The new range of Sandvik WX rubber media combines the high accuracy of wire screens, but with the durability of rubber, providing up to 10x longer wear life and up to 50% faster installation time compared to wire mesh, according to the firm. Having equal size panels also means the screen media is interchangeable between decks.

The QA452 comes with Sandvik’s My Fleet telemetry system and seven-year data subscription as standard. This gives 24/7 fleet management, geo-fencing and remote support.

As safety is a high priority for the firm, several features have been included as standard to improve operator and onsite protection: dust suppression spray bars, onboard water pump, safety pull cords and lighting mast are now fitted.