Modern concrete production plants are using technology to offer more sophisticated mix recipes as Patrick Smith reports. The growing trend towards ever more sophisticated concrete recipes calls for fully developed mixing technology. Companies are responding to the challenges with equipment that offers new levels of sophistication including computer controls and units that can deliver a huge variety of mix recipes.

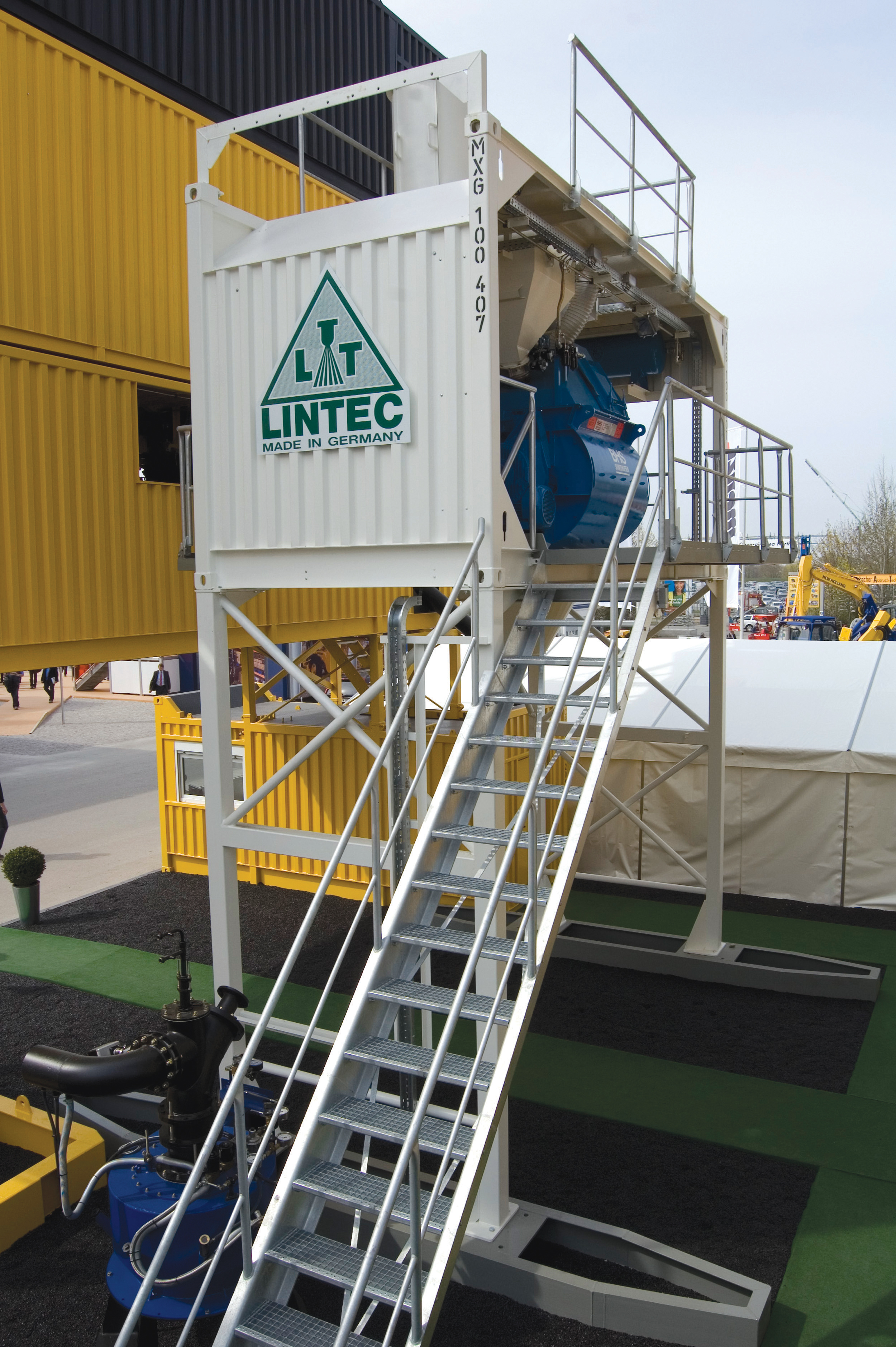

Lintec's new CC 1500 B concrete mixing plant launched at Bauma

Modern concrete production plants are using technology to offer more sophisticated mix recipes as Patrick Smith reports

The growing trend towards ever more sophisticated concrete recipes calls for fully developed mixing technology. Companies are responding to the challenges with equipment that offers new levels of sophistication including computer controls and units that can deliver a huge variety of mix recipes.For example,

Amman says that its special combination enables all plant components to be fine-tuned and it guarantees concrete mixes that fulfill the most stringent demands on quality.

"The newly-developed mixer camera from Ammann provides an insight into the otherwise concealed mixing process. The camera is installed in a ball and swivels out of the mixing chamber during filling and cleaning to protect the lens against damage and contamination. The mixing and discharging processes can be monitored on-screen. The field of view can easily be adjusted within a wide range," says Ammann.

Its Amix twin-shaft paddle mixer is suitable for every mixing task and meets mix quality requirements even for liquid SCC (self-compacting concrete), while has developed a consistency measurement method to document meaningful results that is "not based exclusively on the commonplace drive motor load pick-up measurement method." Ammann is also working on a semi-mobile plant with a large-volume Amix mixer to meet the demand for a high-output plant that can be relocated at low cost, and the new mixing/weighing level is said to be suitable for tower plants, horizontal plants and for conversions to existing plants.

"The ergonomic and safe design grants easy access to plant components, thereby further reducing maintenance outlay. The mixing level has a discharge output of up to 160m³/hour and offers room for concrete mixers up to a batch size of 4m³," says Ammann.

"The arrangement of the scales for aggregate, cement and additive on the weighing level is functional and space-saving. This leaves enough room for manual or automated additive metering." Among the company concrete plant range are the Powermix stationary tower plant; Baumix tower plant for large construction sites; Global Concrete flexible horizontal plant and JustWhite, a semi-mobile concrete mixing plant which has an output of 70m³/hour and is equipped with Ammann's twinshaft paddle mixer Amix2_3.00B with a batch size of 1.5m³ and with the company's as1 control system. Both components also feature in much larger plants.

Containerised newcomers

Lintec produces its asphalt and concrete mixing plants in 100% ISO sea container dimensions, made up of easy transport units with all plant components already pre-installed into the containers when they leave the factory.Lintec claims its containerised mixing plants allow short erection and dismantling time; no concrete foundations are required; they are environment friendly and offer protection against rain and UV-light.

Among recent launches are two new concrete mixing plants, the CC 1500 B, the smallest in its concrete plant range which offer capacities from 60m³ to 240m³/hour, and the CC 3000 B.

Lintec's containerized CC 1500 B concrete mixing plant offers a capacity of 60m³/hour for mobile as well as stationary use and it has a twin shaft compulsory mixer with a mixer size of 1.33m³. The mineral aggregate storage unit has a volume of 90m³ with four compartments and a maximum of six binder/cement silos.

Optional equipment includes 50m³ or 80m³ cement silos; a 1MW heating container and combined additive/water tank.

The CC 3000 B is also containerised and offers a production capacity of 120m³/hour for mobile as well as stationary use and it has a 3m³ twin shaft compulsory mixer.

Mineral aggregate storage comes in an inline 20' unit and inline 40' unit with volumes of 60m³ and 120m³ respectively, and a minimum of three compartments and a maximum of six. Optional equipment is the same as that offered for the CC 1500 B.

MMX dateline

Italian company Simem is offering new super mobile plants, the MMX, which stands for Mobile Mixing eXcellence and which represents the Roman numerals for the year 2010, the year when the company officially launched the "state-of- the-art super mobile batching plants worldwide." "Two patents for industrial property referring to the moving mechanism of the mixer and chassis hood scales were acquired by"The MMX allows for any kind of on site concrete production, even for small volume projects." The aggregate module can be completely transported by one vehicle, and in the transport configuration the hopper walls and loading ramp containing walls collapse into the aggregate module for easy stowing during transport.

Due to the patented movement system for the mixer, the mixing and dosing module is transported as one unit with dimensions that allow for the use of standard equipment.The support structures of the aggregate and mixer modules are all pre-assembled, pre-wired and automated, meaning "it is extremely easy and fast to configure the modules from the transport to the working position." Simem says that the aggregate module is made with a modular concept and can therefore be made expandable by adding additional modules as a priority to expand the number of hoppers available and therefore the types of aggregates. The storage capacity of aggregates can be easily switched from the basic configuration of 80m³ to the configuration of 180m³.

Bulkheads below the aggregate module have a double function. They support the aggregate module due to the large areas of support, making it possible to use the module without the need of civil works, and act as restraints for the loading ramp for aggregate feeding.

"Access to the mixer is made easy thanks to a patented system of rails and hydraulics that moves the weighing devices: when a thorough cleaning of the mixer is necessary, it is possible to move the weighing devices from the work to the transport position, making the internal part of the mixer accessible for a more thorough cleaning or the changing of wear parts," says Simem.

The MMX 5000 plant is equipped with a twin shaft mixer that produces 3.33m³ of compacted concrete, and it is able to guarantee 130m³/hour through 40 cycles, and with a batch size of 3.33m³ the plant is optimised for a loading of 10m³ trucks.

New size category

Meanwhile,The horizontal mixing plants in the range have been operating with great success for a number of years on worldwide markets, and in 2008 alone about 150 mixing plants of this type went into operation, says the company.

Betomix mixing plants are supplied with ring-pan mixers holding between 1-3m³ or with twin-shaft mixers of between 2.25m³ and 6m³ capacities. It has introduced a new model, the Betomix 2.5 with a 2.5m³ twin-shaft mixer, which is a new size category that is Liebherr's response to the current truck mixer capacity trend.

"On European markets in particular, most truck mixers are of 32tonnes gross weight, with a load volume of 7.5m³. On Near East markets, volumes of 10m³ are by no means uncommon. The Betomix 2.5 therefore needs only three or four mixing cycles as the case may be to load these truck mixers," says Liebherr.

Betomix's modular element system and the availability of a large number of options for specific applications offers flexibility in operation, and another advantage of modular construction is that many components are mutually compatible thus cutting delivery times and speeding up assembly work.

Among the many optional extras is the collecting hopper, which can be raised or lowered to accommodate truck heights between 3.6-4m and prevents material from contaminating the plant when truck mixers are being loaded.

"Betomix mixing plant can be specified to suit operating conditions at the intended location. In exceptionally cold regions such as Russia or Scandinavia, Betomix plant is heated and insulated so that it can operate at temperatures well below freezing point. Equally, operation at more than 50°C in the Gulf region in summer presents no problems because the Betomix can be supplied as an option with a flake ice batching system. Adding ice to the intensive mixer lowers the temperature of the concrete." According to Liebherr for use by the concrete goods and precast element industries, the Betomix concept can be integrated into existing production buildings and processes "Configured as tandem or four-unit plants, outputs as high as 1,000m³ of set concrete per hour can be reached."