New products, including additives, are coming onto the market to help reduce the cost of producing bitumen. Patrick smith reports. According to Eng. Paolo Visconti of Iterchimica, environmental issues and the health and safety of operators of manufacturing plants and workers laying bituminous mixes have raised long debates on the possible harmfulness of fumes which are emitted when heating these mixes at the temperatures (160-180°C) required for their production. "If, on the one hand, the effects on operato

A WmA track test involving iterchimica's iterlow-t multi-function liquid additive being carried out lima, Peru, by the emulsiones & Asfaltos compan

New products, including additives, are coming onto the market to help reduce the cost of producing bitumen. Patrick smith reports

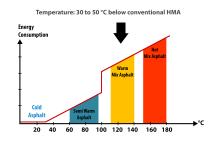

According to Eng. Paolo Visconti of"If, on the one hand, the effects on operators' health are still undergoing clinical studies, on the other hand, the environmental impact of the emissions of harmful substances to the atmosphere is very clear to everyone," says Visconti, who points to "the new era of WMA" (warm mix asphalt), and special additives including Iterlow-T.

He says that high processing temperatures have so far been an indispensable requirement for the mix to achieve the best characteristics, which are only obtained by drying the aggregate, to remove humidity and bond the bitumen to the entire surface of the aggregate.

"These conditions were required in order to assure the workability and compactability of the mix. The need to reduce atmospheric emissions (such as CO2, NOX, VOC and fine dusts); the limited availability of fossil fuels and the requirements of the Kyoto protocol have all forced our industry to turn to environmentally sound production systems with a corresponding reduction of the energy required for production," says Visconti.

"Due to the inability to vary the service temperature of bitumen, which is partly because of the temperature of the binder coming out of the distillation column in the refinery and partly because it is the minimum temperature required to guarantee viscosity and fluidity, we focus on reducing production temperatures by lowering aggregate temperature, which is 94-95% of the total mass of bituminous mix." He says that in order to achieve this goal, a large number of studies have been carried out with the aid of the most advanced technologies and assisted by field tests performed by the biggest companies in the industry.

"These studies focused on the production process and on the change of the physiochemical properties of the components of the bituminous mix.

"Under present conditions, these technologies provide the possibility to produce mixes at temperatures that are close to 125-135°C and allow them to be compacted at 90-100°C, as a function of the different techniques." The most relevant characteristics of the systems which are currently in use, and for which significant references already exist, are the use of two bitumens with different penetration values, one of which is mixed with additives after a foaming process (foam bitumen); zeolites which, by dehydrating at fixed temperatures, promote the bitumen foaming process, and the addition to the bitumen of paraffin waxes featuring a long molecular chain and a high crystallisation point, which operate by changing the physical characteristics of the bitumen." Visconti claims that WMA offers reduced emissions to atmosphere; reduced production costs (burner fuel savings range from 25 to 40%); extended paving season into colder weather, while still obtaining field densities; longer haul distances, while still having workability to spread and compact; the ability to incorporate higher RAP (reclaimed asphalt pavement) content; delayed AC ageing; decreased traffic opening time period, and easier manual operations due to increased workability.

He says that Iterlow-T is a multi-function liquid additive technology developed by Itechimica that can be added to the binder at the storage tank or directly into the AC line using an inexpensive metering pump."Dosage ranges from 0.2% up to 0.5% on the weight of the AC, which is approximately 110-300 grams/tonne of WMA."It does not change the chemical or physical characteristics of the binder, and interacts with the binder structure.

Its chemical action instantly affects the physical characteristics of the mix, allowing it to be produced at 130°C and, therefore, to be spread and compacted at temperatures of around 100°C." According to Visconti, over 80 field tests have been done since 2002 in Europe, and over 600,000tonnes are in place in Europe, Canada and the United States since 2008.

"Such testing activity involved wearing courses, binder layers and base layers.Similar tests have been carried out with the addition of RAP into the mix, in rates that are very close to 25%.

"A direct consequence of reduced temperatures has been the significant decrease and control of fuel consumption and atmospheric emissions. Even hourly output has benefited significantly," says Visconti.

"Moreover, Iterlow-T can be used in HMA to improve the mix performance in severe weather conditions. Though not acting on bitumen viscosity, the surface-active action of Iterlow-T allows the internal friction of the aggregate mixture to be reduced, thus improving its workability and the movement of aggregate during compaction, even at normal service temperatures. Iterlow-T WMA solution does not require changes to the plant, resulting in minimal installation costs."

Busy crossing resurfaced

Resurfacing the heavily trafficked western tunnel of the M25 motorway's Dartford crossing, near London, UK, involved use in the replacement asphalt of a high-tech bitumen binder.This required a 'departure' (permission to deviate from conventional approved practice) from the UK's

Client Connect Plus (it acts on behalf of the Highways Agency and is a consortium of

Altogether 14 surfacing shifts were planned, with a nominal target of 100m of surfacing being carried out on each shift at the 1,400m-long tunnel. Resurfacing was required because of deterioration of the western tunnel's existing 11-year-old surfacing. The tunnel, and in particular its nearside lane, take the vast majority of heavy goods vehicles (HGVs) travelling north.

Jackson Civil Engineering was awarded the main contract with Bardon Contracting responsible for surfacing.

The deck to Dartford's western tunnel is made up of 3.5m-long precast concrete panels, which rest on elastomeric bearings, and whatever asphalt was laid, it had to be one with good flexural characteristics, resistant to fatigue.

It also had to display high resistance to deformation, to combat the effect of the HGVs, and to remain workable at relatively cool temperatures.

These differing requirements called for "an exceptional asphalt binder" and the experts involved, including the technical staff and laboratories of

Both are bound with Endura Z2.

Work started in September 2010 and finished in January 2011, with each shift run as a military operation. At 8pm, personnel, machines and materials literally poured through the portals. Contingency plans and back-up equipment were in place to ensure nothing went wrong (it didn't) and motorists were never alerted to the crossing's highly discreet resurfacing works.

Compact lab

Meanwhile, French companyThe simplified mill, based on the company's Atomix technology, can run on 1litre of emulsion per trial, which enables testing with small quantities of bitumen.

"During one month, this new mill has been tested for several types of emulsion, especially spraying emulsion, which are mainly used for surface dressing," says Emulbitume.

"They have their own specific formulation such as low emulsifier content and high bitumen content.

Standard equipment cannot make high bitumen content emulsion but this new lab can run emulsion with content up to 70%." Different adaptations have been made to be able to manufacture emulsions with low emulsifier contents (typically between 0.15- 0.20%) and high bitumen residue (up to 70%).

"Of course, emulsions with lower bitumen content for cold mixes or tack coat can also be manufactured, giving this new mill the flexibility and ease of use necessary for a laboratory to develop new emulsion designs," says Emulbitume.

Automatic process

"In this way manufacturers can reduce labour costs and any possible mistakes in the loading and production operations," says the company.

Comap says its new automatic emulsion plant is fitted with two storage tanks (bitumen/ water) to guarantee control of the temperatures and of the mixing operations.

On inputting the emulsion formula, the computerised system allows the constant and correct flow of water through the mill, and at the end of the working cycle, the results can be printed including real dosing utilised; real working temperature; emulsion (exit) temperature; quantity produced and production per hour.

"We can also supply continuous big emulsion plants for a production up to 15tonnes/hour, and the Comap automatic emulsion plant meets the new emulsion certification 2011 UNI EN 13808: 2005," says Comap.