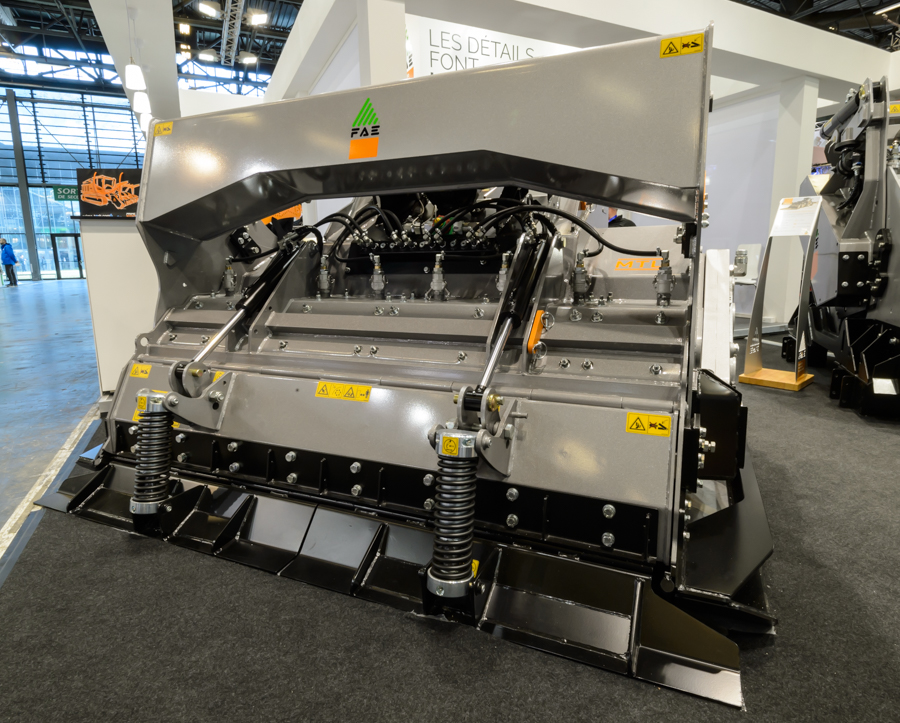

Italian firm FAE Group has developed a novel Multi-Purpose machine range for use in road recycling applications. These versatile units form part of FAE's Construction line and have been designed to be reliable and efficient even in harsh working conditions. The highly rugged items of equipment are designed to deliver fast ground stabilisation working on roads, highways and airports, as well as other major infrastructure jobs. The units can also be used to build and maintain unpaved roads

The Multi-Pu

The `for stabilising purposes

Italian firm 8067 FAE Group has developed a novel Multi-Purpose machine range for use in road recycling applications.

These versatile units form part of FAE's Construction line and have been designed to be reliable and efficient even in harsh working conditions. The highly rugged items of equipment are designed to deliver fast ground stabilisation working on roads, highways and airports, as well as other major infrastructure jobs. The units can also be used to build and maintain unpaved roads

The Multi-Purpose unit can be attached to a conventional tractor quickly and easily. The tractor's PTO powers the grinding head and this allows the tractor to be used for stone crushing and stabilising duties. The FAE units are said to be highly versatile as they can be used to grind rock and asphalt, crush stone and stabilise even in difficult working conditions.

The top-of-the-range model is the MTH, which is designed for use with tractors with power ratings of up to 300kW. The unit can be used to grind layers of rock, crush stones, grind asphalt, and stabilise soil, up to maximum working depth of 500mm.

The machine offers an operating speed of about 500-600 metres/hour, depending on the ground conditions and application. This high speed is achieved due to the MTH's variable geometry crushing chamber and its working depth capability. The innovative chamber design is said to deliver effective crushing. The rotor is designed to be adjusted hydraulically from the cab of the towing machine and this allows the volume of the crushing chamber to be increased as the working depth increases. By penetrating into the soil with only the rotor, the traction forces are said to be lower and fuel consumption is reduced. This allows for faster operating speeds which in turn saves time. The counter blade is made from HARDOX and the adjustable grille on the rear bonnet allow for a granulometry of the output material lower than 35mm.

These versatile units form part of FAE's Construction line and have been designed to be reliable and efficient even in harsh working conditions. The highly rugged items of equipment are designed to deliver fast ground stabilisation working on roads, highways and airports, as well as other major infrastructure jobs. The units can also be used to build and maintain unpaved roads

The Multi-Purpose unit can be attached to a conventional tractor quickly and easily. The tractor's PTO powers the grinding head and this allows the tractor to be used for stone crushing and stabilising duties. The FAE units are said to be highly versatile as they can be used to grind rock and asphalt, crush stone and stabilise even in difficult working conditions.

The top-of-the-range model is the MTH, which is designed for use with tractors with power ratings of up to 300kW. The unit can be used to grind layers of rock, crush stones, grind asphalt, and stabilise soil, up to maximum working depth of 500mm.

The machine offers an operating speed of about 500-600 metres/hour, depending on the ground conditions and application. This high speed is achieved due to the MTH's variable geometry crushing chamber and its working depth capability. The innovative chamber design is said to deliver effective crushing. The rotor is designed to be adjusted hydraulically from the cab of the towing machine and this allows the volume of the crushing chamber to be increased as the working depth increases. By penetrating into the soil with only the rotor, the traction forces are said to be lower and fuel consumption is reduced. This allows for faster operating speeds which in turn saves time. The counter blade is made from HARDOX and the adjustable grille on the rear bonnet allow for a granulometry of the output material lower than 35mm.