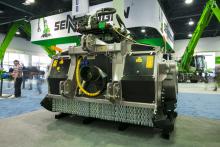

FAE’s STABI/H professional stabiliser for the construction market is the Italian company’s latest-generation model for tractors in the 300-500hp (224-373kW) range. It reaches a maximum working depth of 60cm and is designed for the most demanding projects - roads, motorways, railroads, parking lots, shopping centres, industrial plants and other major infrastructure work.

The stabiliser’s robust design, its newly designed rotor and its innovative tooth holder - developed by FAE - guarantee long working hours in all conditions with unrivalled efficiency, according to the manufacturer.

The FAE STABI/H is available in four models: the STABI/H 225 and 250 for 300-400hp (224-300kW) tractors and the STABI/H/HP (High Power) 225 and 250 for 350-500hp (260-373kW) tractors.

A STABI/H HP 250 is part of the fleet of Steppe Tief- und Strassenbau, a contractor in the German state of Bavaria. Steppe Tief specialises in road construction, excavation and earth moving and with €10 million in revenue and 45 employees. The STABI/H/HP 250 was purchased in August 2020. FGAE says that a decisive factor in selecting this product was how easily the HP model can be adapted to high-powered tractors. Steppe Tief- und Strassenbau uses a customised Fendt 1046 whose black body attracts as much attention as its hefty 460hp (343kW) powerplant.

Pulled by the Fendt tractor, the STABI/H/HP was immediately put to work on a construction site in Hermaringen, a town a few kilometres north of Ulm. “Our job was focused on ground stabilisation by compacting a huge amount of dirt for the expansion of an industrial area, an enormous job given that there were more than 17,000m² to stabilise,” explained company owner Norbert Steppe.

“The material that needed to be recycled was brought on site directly by the customer and split into several layers. On-site work was organised in four stages, each with a daily production of about 3,000-6,000m². We used a total of 400 tonnes of a product provided by building materials group Schwenk as a binding agent, tilling the ground in 50cm deep passes,” he said.

“It was a pure stabilisation job. The dirt we handled was contaminated excavation material which, after stabilisation, reached a grain size of up to 100mm. We did it all working at a speed of 0.6-0. km/h with a fuel consumption of 35-45 litres per hour.”

After finishing the job without any trouble, the STABI/H/HP 250 won the admiration of the Steppe team, who were happy with the results. “We are very satisfied with our FAE STABI which completely meets our earth moving requirements,” said Norbert.

Among the model's main features, the most notable are the variable geometry chamber with a mobile rotor - perfect for very stony soil - and the transmission built into the rotor which makes it possible to process soil with extreme precision.

FAE also recently introduced an update to its heavyweight, multitask attachment with improvements to the systems that control working depth and water injection. The MTH 225 can be used in highway applications such as soil stabilisation, milling thin top layers of road surface or crushing an entire depth of asphalt to turn it into road base. The unit is versatile as it can cope with the presence of stones, rocks and asphalt during the mixing process.