One of the first Wirtgen W 200 Hi cold milling machines off the assembly line is now being used for road recyling work in southern Europe. The versatility of the machine due to its novel 400mm offset drum capability has proven extremely useful for the contractor in Italy. Tuscany–based Endi Asfalti is now using the large and highly productive W 200 Hi for a wide range of milling jobs that would previously have been carried out using a combination of large and small milling machines. The proven W 200 milling

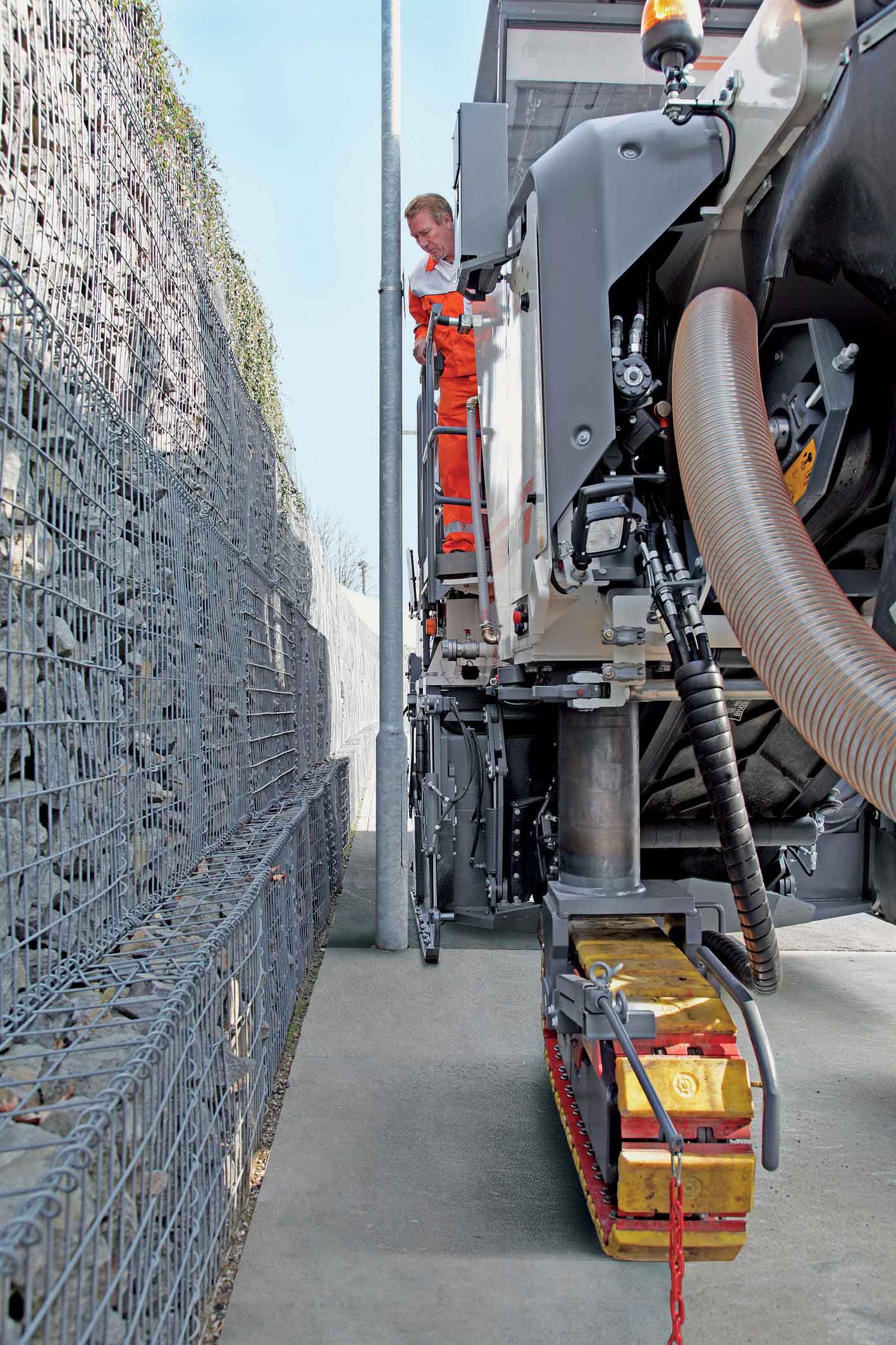

The machine’s ability to work close to walls has been important for the Italian contractor

One of the first 2395 Wirtgen W 200 Hi cold milling machines off the assembly line is now being used for road recyling work in southern Europe

The versatility of the machine due to its novel 400mm offset drum capability has proven extremely useful for the contractor in Italy. Tuscany–based Endi Asfalti is now using the large and highly productive W 200 Hi for a wide range of milling jobs that would previously have been carried out using a combination of large and small milling machines. The proven W 200 milling machine was developed further to become the W 200 Hi, with key features being the hydraulically driven drum with its novel offset system. The offset allows the drum to be displaced 400mm to the right or left. For the Italian contractor, the feature is very useful for handling milling jobs on the often narrow and twisting roads in the area and which in urban areas in particular, also feature walls and buildings in close proximity.

Despite an extensive public transport system, more than 120,000 vehicles/day use the inner-city roads in Modena. This leads to considerable wear on the 850km of roads in the city. As a result, Modena’s Department of Public Works and Maintenance has a strong focus on ensuring the roads are in good condition. In the eastern part of the city, 40mm of the surface course had to be removed over a total stretch of around 2km.

As the area was close to the city’s fruit and vegetable wholesale market with its heavy transport needs, the work had to be carried out quickly and with the minimum disruption to traffic. At the same time, precision was required during the milling work, as utilities located in some sections of the road meant that there were numerous manhole covers. Normally, this would have called for the use of a large milling machine to remove most of the surface course, with a small milling machine then being used to finish off along the edges and around the manhole covers. The versatility of the W 200 Hi due to the hydraulically driven milling drum with its offset capability allows for considerably smaller milling radii. The machine operator was able to use the W 200 Hi first to cut round the manhole covers lining the edge of the road on the right- and left-hand sides. The powerful and productive machine was then used to remove the long sections of roadway in a single pass.

The machine’s versatility was equally useful for carrying out a job in the medieval town centre of Prato. Located 10km north-west of Florence, the town features narrow and winding streets, while different milling depths had to be strictly adhered to in order to avoid damaging the historic stone slabs under the asphalt surface. The narrow road width of just 4-5m was another challenge and would usually have been carried out by a small milling machine.

Roughly 300m of asphalt pavement had to be removed along the Via Carbonaia, one of the roads inside the town's original walls. A milling depth of 50-120mm was needed to reprofile the superstructure for the surface and binder course and at the same time prevent damage to the subgrade. Aided by the automatic LEVEL PRO levelling system, the machine operator was able to comply with the different milling depths specified. The automatic LEVEL PRO levelling system is integrated into the machine control system and constantly compares the current milling depth with the required depth.

Due to the narrow road width, turning the machine around was impossible. But because of the drum offset, the machine was able to work up to the edge on both the right- and left-hand sides, as required. Scaffolding projecting into the road was a further hindrance in Prato, but one which the drum offset was also able to cope with. While the machine chassis and operator's platform ensured a safe distance between the operator and scaffolding, the two zero edges allowed the milling drum assembly to continue cutting through the asphalt pavement right up to the edge of the road. It is of note too that the drum offset system is also of benefit for highway working as it allows the machine to mill right up to the edge of a concrete barrier. And this is a feature the Italian contractor intends to take advantage of on further projects in the future.

The versatility of the machine due to its novel 400mm offset drum capability has proven extremely useful for the contractor in Italy. Tuscany–based Endi Asfalti is now using the large and highly productive W 200 Hi for a wide range of milling jobs that would previously have been carried out using a combination of large and small milling machines. The proven W 200 milling machine was developed further to become the W 200 Hi, with key features being the hydraulically driven drum with its novel offset system. The offset allows the drum to be displaced 400mm to the right or left. For the Italian contractor, the feature is very useful for handling milling jobs on the often narrow and twisting roads in the area and which in urban areas in particular, also feature walls and buildings in close proximity.

Despite an extensive public transport system, more than 120,000 vehicles/day use the inner-city roads in Modena. This leads to considerable wear on the 850km of roads in the city. As a result, Modena’s Department of Public Works and Maintenance has a strong focus on ensuring the roads are in good condition. In the eastern part of the city, 40mm of the surface course had to be removed over a total stretch of around 2km.

As the area was close to the city’s fruit and vegetable wholesale market with its heavy transport needs, the work had to be carried out quickly and with the minimum disruption to traffic. At the same time, precision was required during the milling work, as utilities located in some sections of the road meant that there were numerous manhole covers. Normally, this would have called for the use of a large milling machine to remove most of the surface course, with a small milling machine then being used to finish off along the edges and around the manhole covers. The versatility of the W 200 Hi due to the hydraulically driven milling drum with its offset capability allows for considerably smaller milling radii. The machine operator was able to use the W 200 Hi first to cut round the manhole covers lining the edge of the road on the right- and left-hand sides. The powerful and productive machine was then used to remove the long sections of roadway in a single pass.

The machine’s versatility was equally useful for carrying out a job in the medieval town centre of Prato. Located 10km north-west of Florence, the town features narrow and winding streets, while different milling depths had to be strictly adhered to in order to avoid damaging the historic stone slabs under the asphalt surface. The narrow road width of just 4-5m was another challenge and would usually have been carried out by a small milling machine.

Roughly 300m of asphalt pavement had to be removed along the Via Carbonaia, one of the roads inside the town's original walls. A milling depth of 50-120mm was needed to reprofile the superstructure for the surface and binder course and at the same time prevent damage to the subgrade. Aided by the automatic LEVEL PRO levelling system, the machine operator was able to comply with the different milling depths specified. The automatic LEVEL PRO levelling system is integrated into the machine control system and constantly compares the current milling depth with the required depth.

Due to the narrow road width, turning the machine around was impossible. But because of the drum offset, the machine was able to work up to the edge on both the right- and left-hand sides, as required. Scaffolding projecting into the road was a further hindrance in Prato, but one which the drum offset was also able to cope with. While the machine chassis and operator's platform ensured a safe distance between the operator and scaffolding, the two zero edges allowed the milling drum assembly to continue cutting through the asphalt pavement right up to the edge of the road. It is of note too that the drum offset system is also of benefit for highway working as it allows the machine to mill right up to the edge of a concrete barrier. And this is a feature the Italian contractor intends to take advantage of on further projects in the future.