The market for milling machines is highly competitive and there is an array of firms offering equipment to the global market. German company Wirtgen is the worldwide market leader and has an enormous range of models available, but other companies too are keen to grow market share, with Caterpillar and Roadtec strong in North America and BOMAG, Dynapac and Caterpillar are also pushing hard to build share in Europe for instance. Other companies too are keen to grow their shares of global sales and several of

Wirtgen’s novel W200Hi milling machine features a moveable drum that allows it to plane surfaces alongside kerb edges or highway barriers

Milling machines play a key role in road maintenance tasks and new developments are pushing the envelope in terms of technology. Mike Woof writes

The market for milling machines is highly competitive and there is an array of firms offering equipment to the global market. German company2395 Wirtgen is the worldwide market leader and has an enormous range of models available, but other companies too are keen to grow market share, with 178 Caterpillar and 1252 Roadtec strong in North America and 172 Bomag, 206 Dynapac and Caterpillar are also pushing hard to build share in Europe for instance. Other companies too are keen to grow their shares of global sales and several of the major Chinese manufacturers now offer milling equipment, although these have yet to be seen in any numbers in export markets.

Part of the2779 Fayat Group, Bomag is best known for its compaction line-up but is now broadening its range of milling machines. The firm has developed market share in Europe with its compact milling machines and is looking to replicate this in North America, where it is introducing its rear rotor design BM -35 series. This second generation milling technology is available in three basic variants, the BM 1000 -35, 1200 -35, and 1300 -35. According to Bomag, this new range offers better operator comfort, precision controls and an innovative cutter system.

While developing these machines, Bomag says that it worked closely with some key customers. One target was to minimise downtime so as to increase productivity and maximise cost-effectiveness. A high priority was to increase cutting tool life, while minimising the time needed for tool replacement. With this in mind, Bomag developed a novel BMS 15 interchangeable holder with a single bolt for holder retention and which needs low tightening torque.

The low front face position is said to increase efficiency and milling power while allowing full tooth rotation. Tempered steel is said to increase service life compared with conventional cutting systems. Other important changes include ease of operation and the -35 models have better control layouts as well as a vibration-isolated platform.

161 Atlas Copco’s Dynapac business is keen to reassert its presence in the milling machine market, with its improved designs. The PL350 and PL500 models are compact units for small jobs while the PL1000 is for larger maintenance work and all three share features such as vibration-insulated platforms. The PL1000 has had the most upgrades of the three and is now powered by a low emission 201 Deutz diesel rated at 150kW. This 14.1tonne machine features a 1m-wide cutting width and 300mm cutting depth, with large tanks for fuel and water so as to minimise the need for refilling during a working shift. Peter Lauwers, president of the firm said, “The PL1000 has been beefed up and it has a higher performance. The machine is easier to manoeuvre due to the front axle design.

Top of the range is the 33.5tonne PL2000 and Lauwers said, “The PL2000 we had built earlier, but this new version has a Tier 4 engine.”

A key feature of the PL2000 is its two stage conveyor, which can be swung 45° to either side for truck loading or windrowing. The machine features 162 teeth on its drum and can make a milling cut 2.1m wide by 320mm deep. Of note for the Dynapac brand too is the fact that the firm is now working with a sister company in the Atlas Copco Group that produces drillbits, to develop milling cutters. Given the similar cutting principles within drilling and milling, the company hopes to offer its own long life cutting tools for the planers in the future.

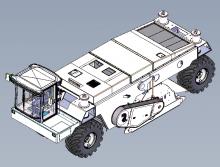

Wirtgen is understandably keen to retain its dominant position and is offering some very sophisticated milling technology aimed at the top end of the market. The firm’s innovative W 200 Hi model is a large machine featuring a hydraulically driven milling drum system. The milling assembly can be moved by 400mm either to the right or left, increasing versatility.

The moveable drum allows contractors to use a large milling machine in small urban traffic operations and on highway sites alongside flowing traffic. The drum assembly means that this large planer can carry out tasks that would normally have to be carried out by a much smaller milling machine. The drum assembly can move to the side while the machine is in operation, so that it can be used to work flush with kerbs or concrete barriers. The machine offers a cutting width of 2.1m and a working depth down to 300mm, while its edge protector can also be raised by 420mm allowing it to work flush with the edge.

Power for the W 200 Hi comes from a 433kW diesel, while the machine features the firm’s sensor-controlled LEVEL PRO automatic level control. This parallel to surface control ensures accurate working depth while the intelligent speed control of the track motors gives optimum traction. Meanwhile it also features a vacuum cutting system to minimise dust emissions as well as the latest low emissions exhaust technology. Other features include good all-round visibility and CCTV equipment for safety.

The company is keen also to reduce tool change-out times for customers and its new HT22 quick-change toolholder system is said to allow more cost-effective operation. The quick-change toolholder system for point-attack cutting tools now features a robust upper part, which can be quickly replaced on the job site. This minimises downtimes and increases the service life of the milling drum. The design of the HT22 system also provides greater contact areas between the upper and lower sections. This is said to allow high cutting forces to be transferred to the lower part of the quick-change toolholder, increasing the life of the milling drum. A large shank cross-section and optimised shank geometry are said to further increase strength, providing greater resistance to deformation. In addition, the maximum longitudinal wear of the upper part of the toolholder has been doubled, while higher pre-tensioning forces due to an optimised screw position provide more reliable pre-tensioning. As a result, service intervals have been extended from 250-500 hours due to the system's more robust construction. All of the firm’s new cold milling machines are now equipped with this latest HT22 quick-change toolholder, while machines already in service earlier can be retrofitted with the system.

The market for milling machines is highly competitive and there is an array of firms offering equipment to the global market. German company

Part of the

While developing these machines, Bomag says that it worked closely with some key customers. One target was to minimise downtime so as to increase productivity and maximise cost-effectiveness. A high priority was to increase cutting tool life, while minimising the time needed for tool replacement. With this in mind, Bomag developed a novel BMS 15 interchangeable holder with a single bolt for holder retention and which needs low tightening torque.

The low front face position is said to increase efficiency and milling power while allowing full tooth rotation. Tempered steel is said to increase service life compared with conventional cutting systems. Other important changes include ease of operation and the -35 models have better control layouts as well as a vibration-isolated platform.

Top of the range is the 33.5tonne PL2000 and Lauwers said, “The PL2000 we had built earlier, but this new version has a Tier 4 engine.”

A key feature of the PL2000 is its two stage conveyor, which can be swung 45° to either side for truck loading or windrowing. The machine features 162 teeth on its drum and can make a milling cut 2.1m wide by 320mm deep. Of note for the Dynapac brand too is the fact that the firm is now working with a sister company in the Atlas Copco Group that produces drillbits, to develop milling cutters. Given the similar cutting principles within drilling and milling, the company hopes to offer its own long life cutting tools for the planers in the future.

Wirtgen is understandably keen to retain its dominant position and is offering some very sophisticated milling technology aimed at the top end of the market. The firm’s innovative W 200 Hi model is a large machine featuring a hydraulically driven milling drum system. The milling assembly can be moved by 400mm either to the right or left, increasing versatility.

The moveable drum allows contractors to use a large milling machine in small urban traffic operations and on highway sites alongside flowing traffic. The drum assembly means that this large planer can carry out tasks that would normally have to be carried out by a much smaller milling machine. The drum assembly can move to the side while the machine is in operation, so that it can be used to work flush with kerbs or concrete barriers. The machine offers a cutting width of 2.1m and a working depth down to 300mm, while its edge protector can also be raised by 420mm allowing it to work flush with the edge.

Power for the W 200 Hi comes from a 433kW diesel, while the machine features the firm’s sensor-controlled LEVEL PRO automatic level control. This parallel to surface control ensures accurate working depth while the intelligent speed control of the track motors gives optimum traction. Meanwhile it also features a vacuum cutting system to minimise dust emissions as well as the latest low emissions exhaust technology. Other features include good all-round visibility and CCTV equipment for safety.

The company is keen also to reduce tool change-out times for customers and its new HT22 quick-change toolholder system is said to allow more cost-effective operation. The quick-change toolholder system for point-attack cutting tools now features a robust upper part, which can be quickly replaced on the job site. This minimises downtimes and increases the service life of the milling drum. The design of the HT22 system also provides greater contact areas between the upper and lower sections. This is said to allow high cutting forces to be transferred to the lower part of the quick-change toolholder, increasing the life of the milling drum. A large shank cross-section and optimised shank geometry are said to further increase strength, providing greater resistance to deformation. In addition, the maximum longitudinal wear of the upper part of the toolholder has been doubled, while higher pre-tensioning forces due to an optimised screw position provide more reliable pre-tensioning. As a result, service intervals have been extended from 250-500 hours due to the system's more robust construction. All of the firm’s new cold milling machines are now equipped with this latest HT22 quick-change toolholder, while machines already in service earlier can be retrofitted with the system.