INO, a world-class centre of expertise in industrial applications for optics and photonics, offers its laser rut easurement system (LRMS), a transverse profiling device that detects and characterises pavement rutting. The organisation says LRMS can acquire full 4m width profiles of a highway lane at normal traffic speeds (up to 100km/hr), using two laser profilers that digitise transverse sections of the pavement.

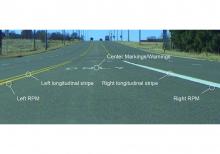

The organisation says LRMS can acquire full 4m width profiles of a highway lane at normal traffic speeds (up to 100km/hr), using two laser profilers that digitise transverse sections of the pavement.

Custom optics and high-power pulsed laser line projectors allow the system to operate in full daylight or in night-time conditions, and in order to keep a constant longitudinal sampling, the vehicle's odometer can be continually monitored.

Road transverse profile data can be collected and processed in real-time on board the vehicle. Rut extraction algorithms have been developed to automatically measure rut depth and width.