In the US, considerable experience has been gained with thin white-topping (TWT), with the technique now being used in other countries as well. In the US hundreds of km of TWT is being paved every year, much of it across the mid-western states.

A variation of white-topping is being used in Oregon to replace badly rutted asphalt truck lanes on primarily long uphill grades with durable, continuously reinforced concrete pavement (CRCP). Oregon has carried out several of these concrete inlay projects over the

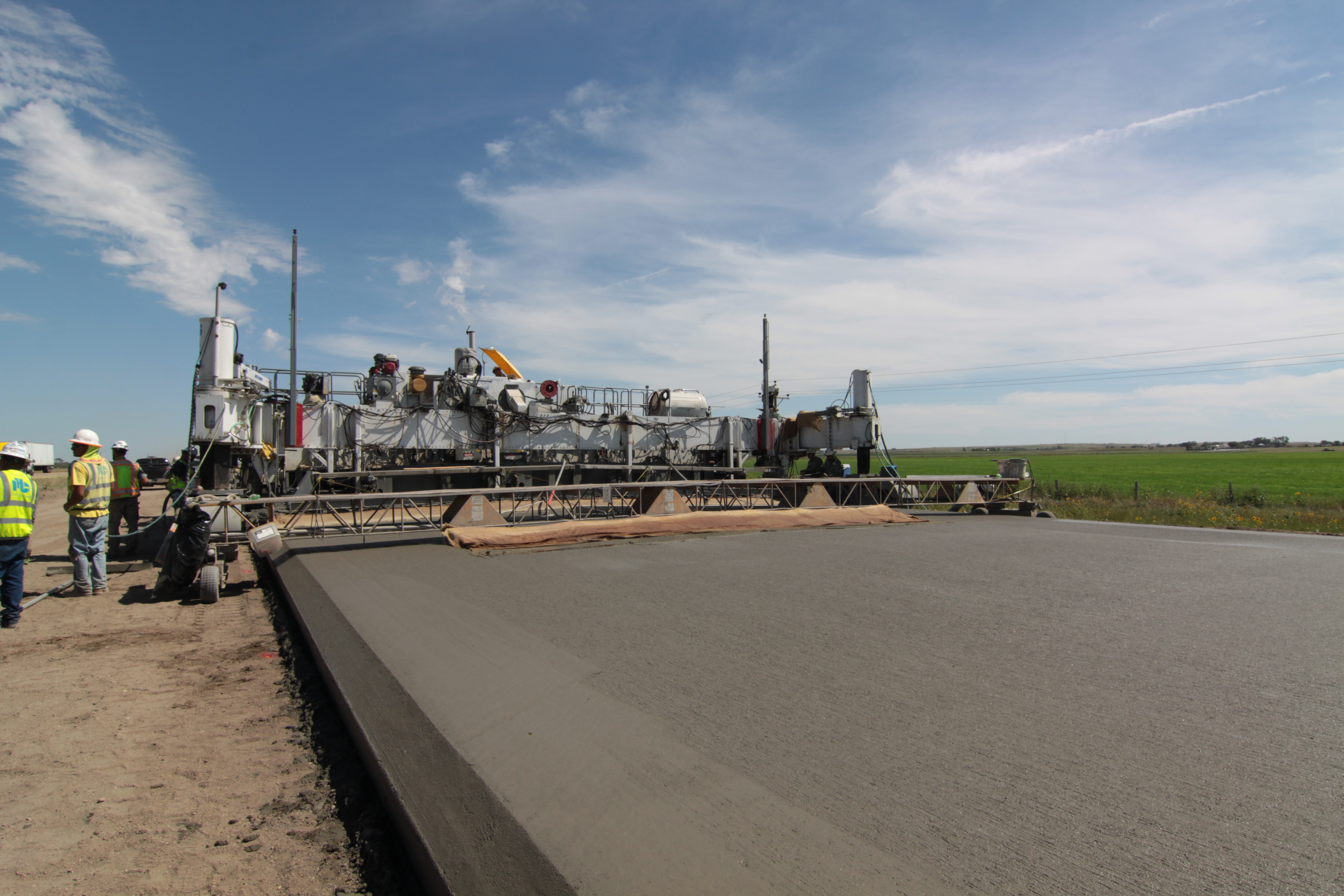

Thin concrete overlays are often used to provide new surfaces on lanes used by heavy trucks

In the US, considerable experience has been gained with thin white-topping (TWT), with the technique now being used in other countries as well. In the US hundreds of km of TWT is being paved every year, much of it across the mid-western states.

A variation of white-topping is being used in Oregon to replace badly rutted asphalt truck lanes on primarily long uphill grades with durable, continuously reinforced concrete pavement (CRCP). Oregon has carried out several of these concrete inlay projects over the last several years. The Concrete Placing Company (CPC) of Boise, Idaho has successfully completed three of these inlay projects in the last three paving seasons. One project in 2014 on I-84 near La Grande, Oregon, and two recently completed projects located on I-84 near Durkee, Oregon and I-5 near Curtin, Oregon.

For these inlay projects in Oregon, the width of the badly rutted truck (slow) lanes are milled out to a nominal 203mm. The asphalt shoulders and passing lanes are left intact providing they are in good condition, and if they are deteriorated they are patched and repaired. The total concrete pavement thickness is 279mm, with a nominal 76mm of new concrete pavement above the existing asphalt surface.

This gives a number of benefits and firstly, the contractor is not trying to match new concrete pavement surfaces to irregular, old asphalt surfaces which would adversely impact concrete smoothness. Secondly, once the new concrete surface reaches a specified strength level, traffic can travel on and off the new concrete pavement. Thirdly, if only the truck (slow) lane is being replaced with CRCP, the new asphalt overlay for the passing lane and shoulders can be brought up to a smooth, new truck lane, concrete surface. And where the passing lane is also replaced with concrete, the paver has a new, machine-placed concrete slab on which to match the companion passing lane slab.

The terrain of the 2014 La Grande project entailed steep grades up to 6%, super-elevated curves up to 10%, and limited construction space only allowing room for the total station robots on one side of the paving spread and concrete trucks on the other side. To feed concrete over the CRCP pavement, a placer/side-feeder with a retractable side-feeding skip was required to let concrete trucks and construction traffic pass. Use of an FAMC/Leica PaveSmart machine control system and GPS guidance for grade and steering reference was provided to the paving train, consisting of the G&Z PS1200, S600, and TC1500.

This saved space on either side of the paving spread. As many as eight265 Leica Geosystems units were used concurrently to guide the G&Z S600 paver along super-elevated curves. With an average 70km haul roundtrip, the average concrete production rates were 153m3/hr. Despite the challenges of this project, the smoothness achieved excellent numbers, scoring a job average PRI of 23mm/km. Tiebars were inserted while paving on the truck climbing lane of this project.

More room was available on the 2016 Durkee project because of the relatively straight road alignment between the eastbound and westbound lanes of I-84. For this project, CPC used its new G&Z MP550 Material Placer to feed the G&Z S600 paver. Curing and longitudinal tining followed with their G&Z TC1500. The challenge of this project was that the concrete plant site was located 24km away from the paving, limiting their average job production rate to 124m3/hr. Despite the challenges with the mix, the job average smoothness was an IRI of 883mm/km.

If existing road conditions permit, the Oregon Department of Transportation’s preferred method of reconstructing roadways involves concrete inlays. Oregon plans to continue this program of replacing rutted asphalt truck lanes with concrete inlays. To maintain efficiency in the flow of traffic, CPC has inlayed one lane, then returned to mill the subsequent lane next to the new overlay. This was achieved on the Anlauf- Elkhead project on I-5 in southern Oregon. The crew had placed a 7.6m and a 3.9m wide section, then returned to add a 3.6m lane. Tiebars were also drilled and epoxied into the slabs.

A variation of white-topping is being used in Oregon to replace badly rutted asphalt truck lanes on primarily long uphill grades with durable, continuously reinforced concrete pavement (CRCP). Oregon has carried out several of these concrete inlay projects over the last several years. The Concrete Placing Company (CPC) of Boise, Idaho has successfully completed three of these inlay projects in the last three paving seasons. One project in 2014 on I-84 near La Grande, Oregon, and two recently completed projects located on I-84 near Durkee, Oregon and I-5 near Curtin, Oregon.

For these inlay projects in Oregon, the width of the badly rutted truck (slow) lanes are milled out to a nominal 203mm. The asphalt shoulders and passing lanes are left intact providing they are in good condition, and if they are deteriorated they are patched and repaired. The total concrete pavement thickness is 279mm, with a nominal 76mm of new concrete pavement above the existing asphalt surface.

This gives a number of benefits and firstly, the contractor is not trying to match new concrete pavement surfaces to irregular, old asphalt surfaces which would adversely impact concrete smoothness. Secondly, once the new concrete surface reaches a specified strength level, traffic can travel on and off the new concrete pavement. Thirdly, if only the truck (slow) lane is being replaced with CRCP, the new asphalt overlay for the passing lane and shoulders can be brought up to a smooth, new truck lane, concrete surface. And where the passing lane is also replaced with concrete, the paver has a new, machine-placed concrete slab on which to match the companion passing lane slab.

The terrain of the 2014 La Grande project entailed steep grades up to 6%, super-elevated curves up to 10%, and limited construction space only allowing room for the total station robots on one side of the paving spread and concrete trucks on the other side. To feed concrete over the CRCP pavement, a placer/side-feeder with a retractable side-feeding skip was required to let concrete trucks and construction traffic pass. Use of an FAMC/Leica PaveSmart machine control system and GPS guidance for grade and steering reference was provided to the paving train, consisting of the G&Z PS1200, S600, and TC1500.

This saved space on either side of the paving spread. As many as eight

More room was available on the 2016 Durkee project because of the relatively straight road alignment between the eastbound and westbound lanes of I-84. For this project, CPC used its new G&Z MP550 Material Placer to feed the G&Z S600 paver. Curing and longitudinal tining followed with their G&Z TC1500. The challenge of this project was that the concrete plant site was located 24km away from the paving, limiting their average job production rate to 124m3/hr. Despite the challenges with the mix, the job average smoothness was an IRI of 883mm/km.

If existing road conditions permit, the Oregon Department of Transportation’s preferred method of reconstructing roadways involves concrete inlays. Oregon plans to continue this program of replacing rutted asphalt truck lanes with concrete inlays. To maintain efficiency in the flow of traffic, CPC has inlayed one lane, then returned to mill the subsequent lane next to the new overlay. This was achieved on the Anlauf- Elkhead project on I-5 in southern Oregon. The crew had placed a 7.6m and a 3.9m wide section, then returned to add a 3.6m lane. Tiebars were also drilled and epoxied into the slabs.