This month’s round-up looks at new equipment from a number of manufacturers and a new bitumen testing service in the UK from global player Intertek - Kristina Smith reports

CONTROLS GROUP has unveiled new machines from each of its specialist divisions, including a new triaxial tester from its soil mechanics arm Wykham Farrance; an E-modulus tester from its concrete testing division; and an asphalt binder analyser from PAVELAB SYSTEMS, its asphalt division.

TRITECH is the result of 50 years of developm

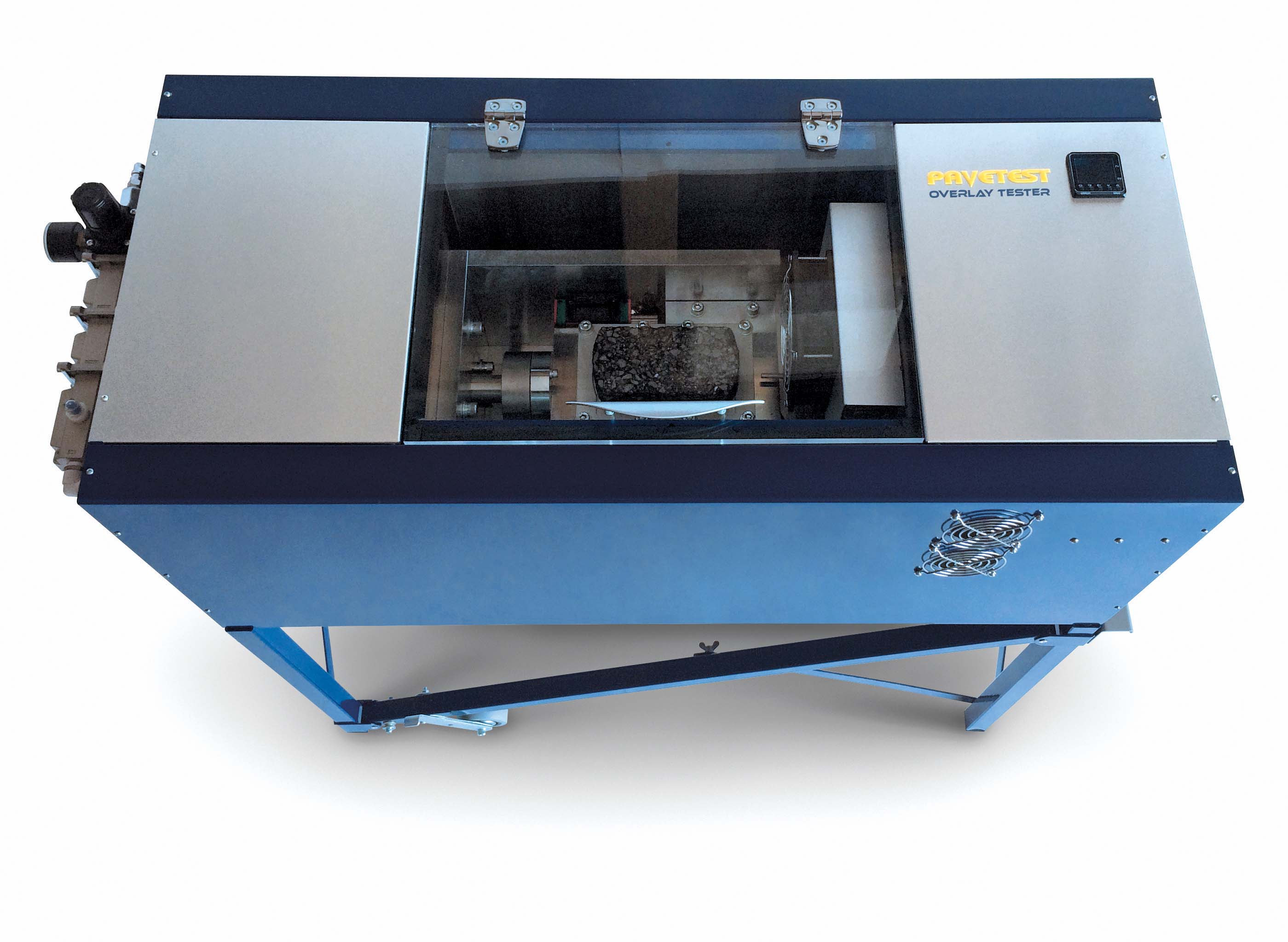

The test Pavetest unit can evaluate the susceptibility of bituminous mixtures to fatigue or reflective testing

This month’s round-up looks at new equipment from a number of manufacturers and a new bitumen testing service in the UK from global player Intertek - Kristina Smith reports

2139 CONTROLS GROUP has unveiled new machines from each of its specialist divisions, including a new triaxial tester from its soil mechanics arm Wykham Farrance; an E-modulus tester from its concrete testing division; and an asphalt binder analyser from PAVELAB SYSTEMS, its asphalt division.

TRITECH is the result of 50 years of development of triaxial testing machines by Wykham Farrance. This latest model has been designed for advanced soil testing laboratories and research laboratories that require high-quality tests and high production rates. As well as triaxial tests, TRITECH can also be used for CBR, Marshall and other general tests.

Described by CONTROLS as ‘top-of-the-range’, TRITECH machines are based on heavy-duty triaxial load frames which have been designed to eliminate vibration, which can affect the specimen under test. They can be used as part of a computer-controlled automatic testing system or as a stand-alone unit under manual control.

TRITECH is equipped with built-in data acquisition with a touchscreen display mounted on the side. The panel and display are protected from water and dust by a waterproof membrane.

A LAN connection and dedicated software allows remote control from a PC. In remote control mode the software allows the user to control the main functions. Users can also calibrate the channels with linear, polynomial and multi-coefficient calibration mode, and display the readings.

CONTROLS has designed its AUTOMAX E-Modulus, which determines Elastic Modulus and Poisson’s Ratio, with the aim of achieving more accurate results. According to CONTROLS, the accuracy of the console depends on the precise control of oil flow by a double-stage hydraulic pump.

The firm’s concrete division has also launched a new Automatic digital mortar mixer with programmable mixing cycles which conform to a variety of standards. And the recently introduced VICAMATIC-2 can then be used to automatically test the sample for setting time.

The AUTOMAX E-Modulus is compatible with small-capacity frames for testing cement and mortar specimens, and high-capacity frames for concrete blocks and cores. It can also be used for automatic compression, flexure and splitting tests on concrete and cement when connected to suitable testing frames. Tests can be set up to conform to various international standards, including DIN 1048/1, ASTM C469, BS 1881:121, ISO 6784 and UNI 6556.

From PAVELAB SYSTEMS, the PAVELAB50 is the second generation of automatic, closed-loop bitumen and binder extractors. It can be used either to determine the binder content in a sample, or to recover a bitumen sample which can then be used for tests such as penetration or softening.

The machine first separates bitumen and filler from the sample by washing with solvent and ultrasonic motion; the resulting liquid is centrifuged and the filler separated; the aggregates and filler are dried by forced air circulation and then the solvent recovered by condensation. The standard PABELAB50 can be upgraded with a method of weighing the sample at the end of each stage. The machine’s software records the weights and makes automatic calculations.

PAVELAB SYSTEMS is also launching a new fully-automatic penetrometer, PIVOT, which conforms to all the main international standards. A stepper motor lowers the needle precisely and the starting point is detected automatically. The penetration test is performed and recorded automatically, according to the parameters defined by the user.

Also new for asphalt testing is the Rolling Thin Film Oven (RTFOT) which determines the resistance to hardening of an asphalt mix under the influence of heat and air. The oven has a touchscreen colour display control panel, including timer function, visual warnings and digital air flow indicator.

These machines will be on display at688 bauma, alongside the AMPT PRO, the latest generation Asphalt Mixture Performance Tester from CONTROLS’ specialist division 3912 IPC Global, which was featured in the November/December 2015 issue of World Highways.

7592 Fairbanks says this instrument is ideal for ‘harsh, dry environments’.

The scale platform is available in two platform sizes: 356mm by 457mm (14 inch by 18 inch) with a capacity of 132kg (60lb), 220kg (100 lb) or 440kg (200 lb) and 457mm by 607mm (18inch x 24inch) with a capacity of 660kg (300lb) or 3123kg (600 lb). Features include overload stops at all four corners of the frame to prevent damage to the load cell. It also has large-diameter feet that can be adjusted by up to 50mm to compensate for irregular surfaces.

Fairbanks will supply the Series 5 scales as a stand-alone scale with the base only or in a package with added pillar with a choice of several Fairbanks instruments on top of the pillar. The scales can also be supplied with a ball-top cover, to aid moving loads on and off them.

Intertek reports that it has invested significantly in bitumen testing equipment at its West Thurrock laboratory in the south-east of the UK so that it can test to BS EN 58, BS EN 13924-2, BS EN 12591 and BS EN 13808 specifications. Some of the company’s other laboratories around the UK will also be capable of carrying out tests and Intertek will also provide on-site testing.

Intertek’s West Thurrock laboratory manager Lee Burton said, “It is vital for customers to know that the bitumen they have bought does not deteriorate while stored in tanks or loaded into trucks, so we provide daily checks to ensure the conditions in the tank remain stable and that the specification of the product remains unchanged.”

The new laboratory adds to Intertek’s existing bitumen testing capability in Europe, which was previously provided by its bitumen laboratory in France which tests samples from Europe and beyond.

282 Matest company Pavestest has launched its 7955 Pavetest Overlay Tester, which aims to test the susceptibility of bituminous mixtures to fatigue or reflective testing. The US’ Texas DOT developed the Test Procedure for the Overlay Test, Tex-248-F, with a national standard, ASTM Standard WK 26816, reported to be under preparation. The Texas DOT developed the test in response to problems with cracking.

“Over the years, asphalt mixture has gradually become stiffer, in an attempt to overcome rutting and the move towards the increased use of recycled materials has increased susceptibility of these mixtures to fatigue and reflection cracking,” said Pavetest managing director Con Sinadinos. “Furthermore, the need to rehabilitate pavements using thin asphalt overlays and preserve existing pavements with routine crack sealing makes the need for a cracking test more critical than ever.”

The Pavetest Overlay Tester is a servo-pneumatic controlled testing machine which uses digital control of a high-performance servo valve to provide accurate cyclic and monotonic loading of a specimen which is a round-ended beam. The system comprises a load frame, with one fixed and one moving plate, temperature control system, Control and Data Acquisition System (CDAS) and silent air compressor. The specimen is glued to two plates and this assembly is placed in the machine for testing. This is intended to simulate the action of movement that occurs in the proximity of joints or cracks, which result in reflection cracking in overlays.

Some of the tester’s features include thermoelectric heating and cooling – rather than conventional heating elements and refrigeration units; a silent air compressor, which makes the unit stand-alone and avoids the risk of introducing moisture or contamination from an external compressed air supply; a dial gauge; and TestLab software and control and data acquisition (CDAS).

TRITECH is the result of 50 years of development of triaxial testing machines by Wykham Farrance. This latest model has been designed for advanced soil testing laboratories and research laboratories that require high-quality tests and high production rates. As well as triaxial tests, TRITECH can also be used for CBR, Marshall and other general tests.

Described by CONTROLS as ‘top-of-the-range’, TRITECH machines are based on heavy-duty triaxial load frames which have been designed to eliminate vibration, which can affect the specimen under test. They can be used as part of a computer-controlled automatic testing system or as a stand-alone unit under manual control.

TRITECH is equipped with built-in data acquisition with a touchscreen display mounted on the side. The panel and display are protected from water and dust by a waterproof membrane.

A LAN connection and dedicated software allows remote control from a PC. In remote control mode the software allows the user to control the main functions. Users can also calibrate the channels with linear, polynomial and multi-coefficient calibration mode, and display the readings.

CONTROLS has designed its AUTOMAX E-Modulus, which determines Elastic Modulus and Poisson’s Ratio, with the aim of achieving more accurate results. According to CONTROLS, the accuracy of the console depends on the precise control of oil flow by a double-stage hydraulic pump.

The firm’s concrete division has also launched a new Automatic digital mortar mixer with programmable mixing cycles which conform to a variety of standards. And the recently introduced VICAMATIC-2 can then be used to automatically test the sample for setting time.

The AUTOMAX E-Modulus is compatible with small-capacity frames for testing cement and mortar specimens, and high-capacity frames for concrete blocks and cores. It can also be used for automatic compression, flexure and splitting tests on concrete and cement when connected to suitable testing frames. Tests can be set up to conform to various international standards, including DIN 1048/1, ASTM C469, BS 1881:121, ISO 6784 and UNI 6556.

From PAVELAB SYSTEMS, the PAVELAB50 is the second generation of automatic, closed-loop bitumen and binder extractors. It can be used either to determine the binder content in a sample, or to recover a bitumen sample which can then be used for tests such as penetration or softening.

The machine first separates bitumen and filler from the sample by washing with solvent and ultrasonic motion; the resulting liquid is centrifuged and the filler separated; the aggregates and filler are dried by forced air circulation and then the solvent recovered by condensation. The standard PABELAB50 can be upgraded with a method of weighing the sample at the end of each stage. The machine’s software records the weights and makes automatic calculations.

PAVELAB SYSTEMS is also launching a new fully-automatic penetrometer, PIVOT, which conforms to all the main international standards. A stepper motor lowers the needle precisely and the starting point is detected automatically. The penetration test is performed and recorded automatically, according to the parameters defined by the user.

Also new for asphalt testing is the Rolling Thin Film Oven (RTFOT) which determines the resistance to hardening of an asphalt mix under the influence of heat and air. The oven has a touchscreen colour display control panel, including timer function, visual warnings and digital air flow indicator.

These machines will be on display at

Fairbanks Scales

Kansas City company Fairbank Scales has launched its Series 5 bench scales, designed to withstand the rigours of heavy-duty testing. With a scale base made from mild steel and tubular cast aluminium and a stainless steel cover to protect the load cell and increase the equipment’s durability,The scale platform is available in two platform sizes: 356mm by 457mm (14 inch by 18 inch) with a capacity of 132kg (60lb), 220kg (100 lb) or 440kg (200 lb) and 457mm by 607mm (18inch x 24inch) with a capacity of 660kg (300lb) or 3123kg (600 lb). Features include overload stops at all four corners of the frame to prevent damage to the load cell. It also has large-diameter feet that can be adjusted by up to 50mm to compensate for irregular surfaces.

Fairbanks will supply the Series 5 scales as a stand-alone scale with the base only or in a package with added pillar with a choice of several Fairbanks instruments on top of the pillar. The scales can also be supplied with a ball-top cover, to aid moving loads on and off them.

Intertek

Global testing, inspection and certification company Intertek has launched a new bitumen testing service in the UK which it says will offer ‘round-the-clock’ services to its clients. The move has been driven by the UK Government’s plans to invest in the road network, ‘the biggest investment in road infrastructure since the 1970s’, says Intertek.Intertek reports that it has invested significantly in bitumen testing equipment at its West Thurrock laboratory in the south-east of the UK so that it can test to BS EN 58, BS EN 13924-2, BS EN 12591 and BS EN 13808 specifications. Some of the company’s other laboratories around the UK will also be capable of carrying out tests and Intertek will also provide on-site testing.

Intertek’s West Thurrock laboratory manager Lee Burton said, “It is vital for customers to know that the bitumen they have bought does not deteriorate while stored in tanks or loaded into trucks, so we provide daily checks to ensure the conditions in the tank remain stable and that the specification of the product remains unchanged.”

The new laboratory adds to Intertek’s existing bitumen testing capability in Europe, which was previously provided by its bitumen laboratory in France which tests samples from Europe and beyond.

Pavetest

“Over the years, asphalt mixture has gradually become stiffer, in an attempt to overcome rutting and the move towards the increased use of recycled materials has increased susceptibility of these mixtures to fatigue and reflection cracking,” said Pavetest managing director Con Sinadinos. “Furthermore, the need to rehabilitate pavements using thin asphalt overlays and preserve existing pavements with routine crack sealing makes the need for a cracking test more critical than ever.”

The Pavetest Overlay Tester is a servo-pneumatic controlled testing machine which uses digital control of a high-performance servo valve to provide accurate cyclic and monotonic loading of a specimen which is a round-ended beam. The system comprises a load frame, with one fixed and one moving plate, temperature control system, Control and Data Acquisition System (CDAS) and silent air compressor. The specimen is glued to two plates and this assembly is placed in the machine for testing. This is intended to simulate the action of movement that occurs in the proximity of joints or cracks, which result in reflection cracking in overlays.

Some of the tester’s features include thermoelectric heating and cooling – rather than conventional heating elements and refrigeration units; a silent air compressor, which makes the unit stand-alone and avoids the risk of introducing moisture or contamination from an external compressed air supply; a dial gauge; and TestLab software and control and data acquisition (CDAS).