Real time information on asphalt density and uniformity can boost construction quality - *Roger Roberts, GSSI. Properly compacted asphalt is a major factor in the lifespan of a road, as inadequately compacted asphalt deteriorates at a more rapid rate than properly compacted material. With the billions spent on road construction and repairs each year, it has become a matter of urgency to find new technologies that can ensure the integrity of asphalt on newly paved roads. New radio wave technology is now avai

Effective compaction can help ensure that mat quality is optimised

Real time information on asphalt density and uniformity can boost construction quality - *Roger Roberts, 8095 GSSI

Properly compacted asphalt is a major factor in the lifespan of a road, as inadequately compacted asphalt deteriorates at a more rapid rate than properly compacted material. With the billions spent on road construction and repairs each year, it has become a matter of urgency to find new technologies that can ensure the integrity of asphalt on newly paved roads. New radio wave technology is now available to non-destructively determine asphalt density during application.

The air void content within asphalt varies based on the amount of compaction during asphalt emplacement and variations in the asphalt mix composition. Asphalt with too many air voids (often considered to be more than 8%) deteriorates at a more rapid rate. Too few air voids (less than 3%) results from over-compacted asphalt, which is also undesirable.

In either case, the asphalt is subject to early failure and the road’s lifetime is less than asphalt that contains the optimal air void content.

Construction engineers are looking for that sweet spot where the compaction of the asphalt when it is laid down is optimal. They typically assess asphalt by measuring density variations, which can be used to calculate the air void content.

To ensure optimal compaction, asphalt should be kept at a specific temperature range as it is being laid. If the paving machine and transfer vehicles do not do a good job keeping the material uniformly hot, there can be cold patch areas. When the roller is used on areas outside the optimal temperature range, it cannot properly compact the material. For example, such cold patches may occur if the asphalt paver is refilled from end-dump trucks, which cool the asphalt more near the metal sides and end of the truck than in the middle. Some poorly-paved roads have regularly spaced defects associated with end-dump truck refills.

It may not be possible to notice these areas at first, but they are likely to become obvious later. In fact, there are many roads where it is possible to observe a cold patch every several hundred metres that is starting to deteriorate – turning into a ravelled section in the road. If the work crew does not catch the problem during paving, the road may need to be repaved far sooner than if the material was properly applied.

Another compaction issue occurs when the established rolling pattern is not properly followed. The rolling pattern refers to the number of times, speed, and lap pattern rollers should employ when rolling new asphalt to achieve the optimum compaction. If the paving crew misses a section and does not compact the material with the proper number of rolls, they can create areas where compaction is faulty.

Discovering and correcting any rolling pattern issues during the first few days of a paving job benefits both the owner and contractor, since contract specifications may include requirements on how asphalt is laid down in terms of acceptable void content. Contracts may also include a bonus for getting to the specific asphalt void content range – or a penalty if the crew goes outside the specified void content range.

There are several available methods that can be used to measure asphalt density variations, which are then used to calculate void content variation. One non-destructive testing (NDT) method is the nuclear density gauge, which consists of a radiation source that emits a cloud of particles and a sensor that counts the received particles that are scattered back by the test material. By calculating the percentage of particles that return to the sensor, the gauge can be calibrated to measure the density and inner structure of the test material.

While quite accurate, the nuclear gauge has several disadvantages. The gauge is placed on asphalt and measurements are taken over a specific period of time, usually a few minutes or less. The method requires contact, with the device required to remain stationary at the measurement point. Due to the length of time required for the measurement, nuclear gauge measurements are taken sparsely. Collection of only these spot measurements does not adequately capture all the asphalt’s variability.

Also, because it uses radioactive material, the nuclear gauge requires user training and secure storage. There are also special transportation requirements. Relicensing, maintenance, and recalibration fees can cost about US$2000/year.

Similar to a nuclear gauge, the non-nuclear density gauge measures electrical impedance; a calibration procedure is then performed to correlate it to density. Like the nuclear density gauge, the method is quite limited, because it samples only very small portions of the asphalt.

Because the nuclear and non-nuclear density gauges may collect only one value over a large area, they are unable to catch all the variations in void content that may be important to ensuring a quality paving job.

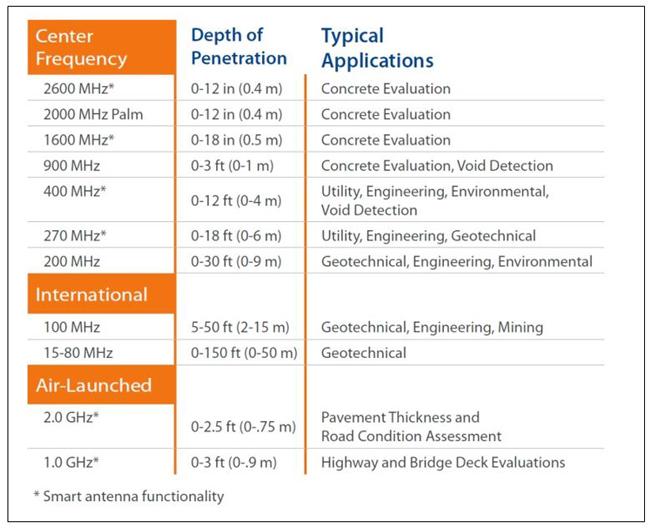

Another NDT option is the use of radio waves, which can be used to obtain real-time measurements over a large swathe of pavement in short periods of time. Radio wave reflections from the asphalt can be used to directly calculate the asphalt dielectric values, which are then correlated with the new pavement’s void content, a relative indication of density.

One other method that should be mentioned is coring, when a core is extracted from the asphalt so that its properties can be measured. Coring is used as a primary asphalt compaction evaluation method and is used as back up for measurements from other methods. Coring is done on a limited basis, so it often under-represents the true variability in asphalt void content.

The initial relationship between void content and road condition has been known for a long time. In the late 1990s, researchers at the Texas Transportation Institute (TTI) discovered the relationship between the dielectric calculated by ground penetrating radar (GPR), an application-specific use of radio waves, and void content.

Researchers later developed a working methodology for use of infrared and radio wave technologies for improving the assessment of asphalt mixture and compaction quality. They then looked for a way to commercialise it so it could be easily used by state departments of transportation.

Previously, use of the GPR technique required specialised equipment, a great deal of data interpretation, and a number of manual steps. In 2013, TTI began working with GSSI to package the device components into a streamlined and operator-friendly device that would provide real-time profiling of asphalt mixture uniformity. The work was done as part of the Federal Highway Administration’s Strategic Highway Research Program (SHRP 2).

Over the next few years, GSSI developed the technology into the PaveScan RDM, which TTI used in several pilot studies. The noncontact PaveScan technology uses a sensor that typically outputs a measurement each half-foot along the lane travelled, so a mile’s worth of data includes roughly 10,000 measurements for each sensor used.

TTI found that the new PaveScan system overcomes hardware, data processing, and staff expertise hurdles that existed in the past. According to TTI, “The utility of GPR was realised on all pilot projects, where the radar results provided quantitative assessment of density and uniformity.”

GSSI later developed a three-channel system that can be vehicle-mounted to obtain moving void content measurements in one pass, covering both wheel paths and between the wheel paths. One sensor is located in one wheel path, one in the middle and one in the other wheel path – so three measurements are output for each half-foot along the lane travelled. In this way, a mile’s worth of data includes roughly 30,000 measurements – all collected in a mere 20 minutes.

The PaveScan RDM system has a number of benefits. First of all, it is a way of ensuring asphalt integrity of newly paved roads. Now, when a contractor lays down a new road, the asphalt void content over the entire area paved is accurately calculated, so both contractors and the owner of the road are satisfied. Secondly, the system is easy to use, reducing the amount of expertise needed to a manageable level. Thirdly, it is a very rapid method, adaptable to being put on a vehicle. The safety benefits of not having someone standing in a lane next to moving traffic are huge.

Previously, the prototype PaveScan unit developed by GSSI was used in the evaluations done as part of the SHRP 2 project. This year, GSSI delivered a production 3-channel unit to TTI, which is being used to further its research. Additional production units have been purchased with SHRP 2 funding by the Minnesota Department of Transportation, the Maine Department of Transportation, and the Nebraska Department of Transportation. By June 2016, there will be four units in the field, working to ensure that tax dollars allocated for road construction are being used wisely.

*Roger Roberts works at GSSI References

Non-Nuclear Methods for HMA Density Measurements, MBTC 2075 Final Report, Williams, Stacey, G., 2008. Pre-Implementation of Infrared and Ground- Penetrating Radar Technologies for Improving Asphalt Mixture Quality, Strategic Highway Research Program, Transportation Research Board of the National Academies, Stephen Sebesta and Tom Scullion, Texas A&M Transportation Institute, The Texas A&M University System, College Station, Texas, © 2014 National Academy of Sciences. All rights reserved.

Properly compacted asphalt is a major factor in the lifespan of a road, as inadequately compacted asphalt deteriorates at a more rapid rate than properly compacted material. With the billions spent on road construction and repairs each year, it has become a matter of urgency to find new technologies that can ensure the integrity of asphalt on newly paved roads. New radio wave technology is now available to non-destructively determine asphalt density during application.

The air void content within asphalt varies based on the amount of compaction during asphalt emplacement and variations in the asphalt mix composition. Asphalt with too many air voids (often considered to be more than 8%) deteriorates at a more rapid rate. Too few air voids (less than 3%) results from over-compacted asphalt, which is also undesirable.

In either case, the asphalt is subject to early failure and the road’s lifetime is less than asphalt that contains the optimal air void content.

Construction engineers are looking for that sweet spot where the compaction of the asphalt when it is laid down is optimal. They typically assess asphalt by measuring density variations, which can be used to calculate the air void content.

To ensure optimal compaction, asphalt should be kept at a specific temperature range as it is being laid. If the paving machine and transfer vehicles do not do a good job keeping the material uniformly hot, there can be cold patch areas. When the roller is used on areas outside the optimal temperature range, it cannot properly compact the material. For example, such cold patches may occur if the asphalt paver is refilled from end-dump trucks, which cool the asphalt more near the metal sides and end of the truck than in the middle. Some poorly-paved roads have regularly spaced defects associated with end-dump truck refills.

It may not be possible to notice these areas at first, but they are likely to become obvious later. In fact, there are many roads where it is possible to observe a cold patch every several hundred metres that is starting to deteriorate – turning into a ravelled section in the road. If the work crew does not catch the problem during paving, the road may need to be repaved far sooner than if the material was properly applied.

Another compaction issue occurs when the established rolling pattern is not properly followed. The rolling pattern refers to the number of times, speed, and lap pattern rollers should employ when rolling new asphalt to achieve the optimum compaction. If the paving crew misses a section and does not compact the material with the proper number of rolls, they can create areas where compaction is faulty.

Discovering and correcting any rolling pattern issues during the first few days of a paving job benefits both the owner and contractor, since contract specifications may include requirements on how asphalt is laid down in terms of acceptable void content. Contracts may also include a bonus for getting to the specific asphalt void content range – or a penalty if the crew goes outside the specified void content range.

There are several available methods that can be used to measure asphalt density variations, which are then used to calculate void content variation. One non-destructive testing (NDT) method is the nuclear density gauge, which consists of a radiation source that emits a cloud of particles and a sensor that counts the received particles that are scattered back by the test material. By calculating the percentage of particles that return to the sensor, the gauge can be calibrated to measure the density and inner structure of the test material.

While quite accurate, the nuclear gauge has several disadvantages. The gauge is placed on asphalt and measurements are taken over a specific period of time, usually a few minutes or less. The method requires contact, with the device required to remain stationary at the measurement point. Due to the length of time required for the measurement, nuclear gauge measurements are taken sparsely. Collection of only these spot measurements does not adequately capture all the asphalt’s variability.

Also, because it uses radioactive material, the nuclear gauge requires user training and secure storage. There are also special transportation requirements. Relicensing, maintenance, and recalibration fees can cost about US$2000/year.

Similar to a nuclear gauge, the non-nuclear density gauge measures electrical impedance; a calibration procedure is then performed to correlate it to density. Like the nuclear density gauge, the method is quite limited, because it samples only very small portions of the asphalt.

Because the nuclear and non-nuclear density gauges may collect only one value over a large area, they are unable to catch all the variations in void content that may be important to ensuring a quality paving job.

Another NDT option is the use of radio waves, which can be used to obtain real-time measurements over a large swathe of pavement in short periods of time. Radio wave reflections from the asphalt can be used to directly calculate the asphalt dielectric values, which are then correlated with the new pavement’s void content, a relative indication of density.

One other method that should be mentioned is coring, when a core is extracted from the asphalt so that its properties can be measured. Coring is used as a primary asphalt compaction evaluation method and is used as back up for measurements from other methods. Coring is done on a limited basis, so it often under-represents the true variability in asphalt void content.

The initial relationship between void content and road condition has been known for a long time. In the late 1990s, researchers at the Texas Transportation Institute (TTI) discovered the relationship between the dielectric calculated by ground penetrating radar (GPR), an application-specific use of radio waves, and void content.

Researchers later developed a working methodology for use of infrared and radio wave technologies for improving the assessment of asphalt mixture and compaction quality. They then looked for a way to commercialise it so it could be easily used by state departments of transportation.

Previously, use of the GPR technique required specialised equipment, a great deal of data interpretation, and a number of manual steps. In 2013, TTI began working with GSSI to package the device components into a streamlined and operator-friendly device that would provide real-time profiling of asphalt mixture uniformity. The work was done as part of the Federal Highway Administration’s Strategic Highway Research Program (SHRP 2).

Over the next few years, GSSI developed the technology into the PaveScan RDM, which TTI used in several pilot studies. The noncontact PaveScan technology uses a sensor that typically outputs a measurement each half-foot along the lane travelled, so a mile’s worth of data includes roughly 10,000 measurements for each sensor used.

TTI found that the new PaveScan system overcomes hardware, data processing, and staff expertise hurdles that existed in the past. According to TTI, “The utility of GPR was realised on all pilot projects, where the radar results provided quantitative assessment of density and uniformity.”

GSSI later developed a three-channel system that can be vehicle-mounted to obtain moving void content measurements in one pass, covering both wheel paths and between the wheel paths. One sensor is located in one wheel path, one in the middle and one in the other wheel path – so three measurements are output for each half-foot along the lane travelled. In this way, a mile’s worth of data includes roughly 30,000 measurements – all collected in a mere 20 minutes.

The PaveScan RDM system has a number of benefits. First of all, it is a way of ensuring asphalt integrity of newly paved roads. Now, when a contractor lays down a new road, the asphalt void content over the entire area paved is accurately calculated, so both contractors and the owner of the road are satisfied. Secondly, the system is easy to use, reducing the amount of expertise needed to a manageable level. Thirdly, it is a very rapid method, adaptable to being put on a vehicle. The safety benefits of not having someone standing in a lane next to moving traffic are huge.

Previously, the prototype PaveScan unit developed by GSSI was used in the evaluations done as part of the SHRP 2 project. This year, GSSI delivered a production 3-channel unit to TTI, which is being used to further its research. Additional production units have been purchased with SHRP 2 funding by the Minnesota Department of Transportation, the Maine Department of Transportation, and the Nebraska Department of Transportation. By June 2016, there will be four units in the field, working to ensure that tax dollars allocated for road construction are being used wisely.

*Roger Roberts works at GSSI References

Non-Nuclear Methods for HMA Density Measurements, MBTC 2075 Final Report, Williams, Stacey, G., 2008. Pre-Implementation of Infrared and Ground- Penetrating Radar Technologies for Improving Asphalt Mixture Quality, Strategic Highway Research Program, Transportation Research Board of the National Academies, Stephen Sebesta and Tom Scullion, Texas A&M Transportation Institute, The Texas A&M University System, College Station, Texas, © 2014 National Academy of Sciences. All rights reserved.