Early detection of pavement defects and the causes of deterioration is essential for effective maintenance planning, writes Dr Alena Uus*

There is a need for optimisation and development of UK highway survey methods that would provide comprehensive information on the surface and subsurface pavement condition and operate at traffic speed, which eliminates the requirement for lane closures.

Performance of non-destructive testing (NDT) methods commonly employed in pavement condition surveys can be potent

An NDT system integrating GRP, IRT and air-coupled ultrasound sensors was developed under the EU FP7 RPB HealTec research project

Early detection of pavement defects and the causes of deterioration is essential for effective maintenance planning, writes Dr Alena Uus*

There is a need for optimisation and development of UK highway survey methods that would provide comprehensive information on the surface and subsurface pavement condition and operate at traffic speed, which eliminates the requirement for lane closures.

Performance of non-destructive testing (NDT) methods commonly employed in pavement condition surveys can be potentially improved by the sensor fusion. Combination of multiple NDT sensors increases the amount of useful information provided to the surveyors. The advantage of this approach was already proven in the cases of integration of ground penetrating radar (GPR) with falling weight deflectometer (FWD) as well as HD (high definition) video cameras with laser profilometers in traditional survey systems1.

Recently, a series of research projects2,3,4 were carried out for comparative analysis of the effectiveness of various NDT techniques in detection of subsurface defects in pavement, bridge deck and tunnel linings including: GPR, ultrasound, infrared thermography (IRT), FWD, impact echo, etc.

Based on different physical phenomena, all these techniques have their own advantages and limitations regarding resolution, maximum penetration depth, noise-to-signal ratio, optimal speed, sensitivity to environmental conditions and other factors affecting interpretation of sensor data. Thus, integration of several of these methods can improve the validity of measurements from individual sensors. This will directly improve the accuracy of pavement condition assessment.

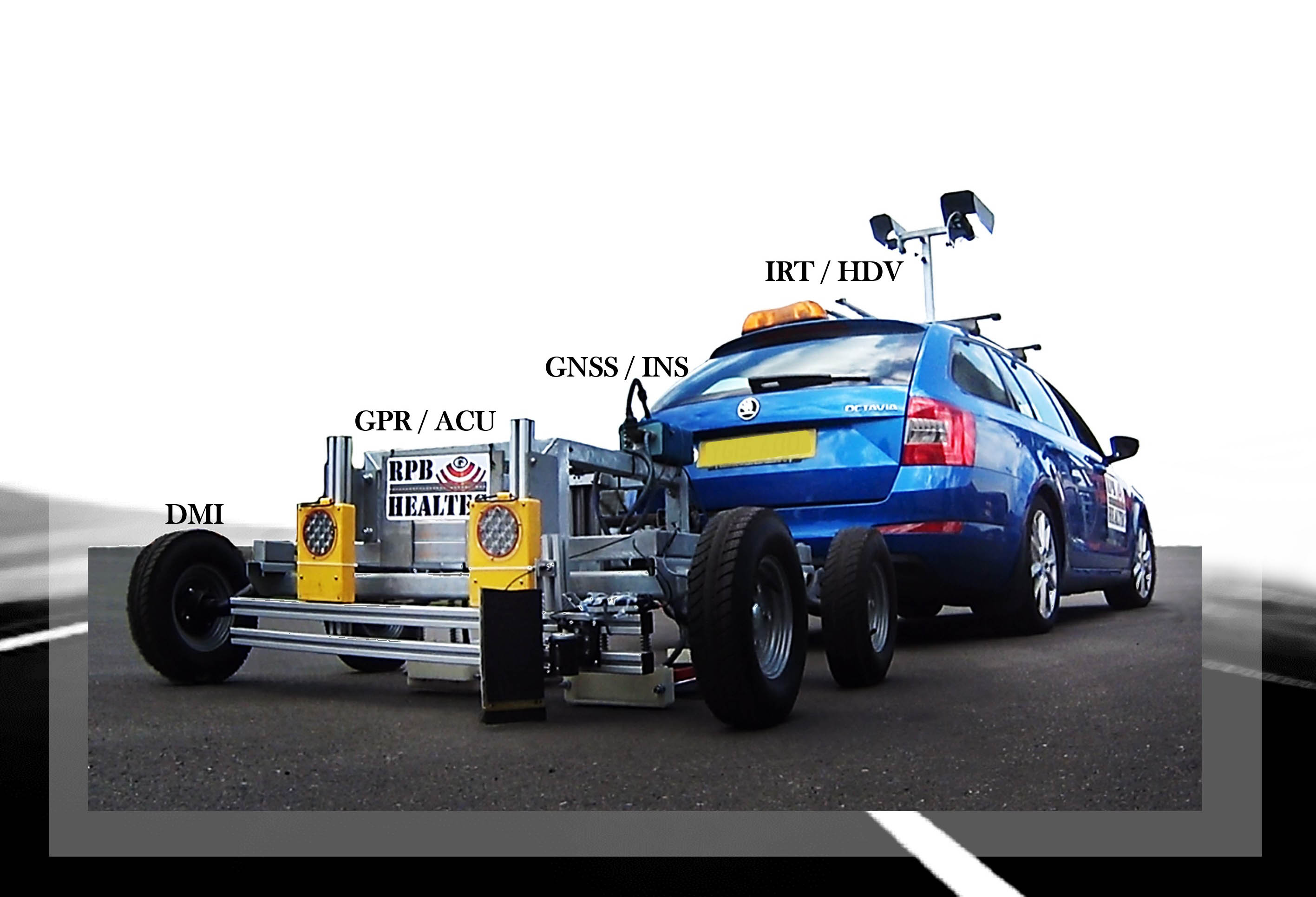

An NDT system based on integration of GRP, IRT and air-coupled ultrasound (ACU) sensors was developed under the EU FP7 %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal RPB HealTec Visit Blog page false http://blogs.city.ac.uk/fp7-rpbhealtec/ false false %> research project5. This set of NDT technologies maximises the coverage of pavement structural condition including detection of surface and subsurface defects, structural and material changes and deterioration regions. The system is specifically designed for traffic speed (40-60kph) highway surveys.

While GPR has been widely employed in pavement and highway infrastructure surveys for many years1,2,3,4 and constitutes the basis for the proposed integrated solution, the application of thermography and ultrasound in pavement inspection has considerable novelty2.

Specifically, IRT is primarily used in bridge deck inspection3,4 or segregation measurements in new HMA layers during construction. This is related to the fact that, in the case of pavement surveys, the procedure for distinguishing features of various subsurface defect types in thermal patterns is not direct and is highly sensitive to environmental and operational conditions.

Classical ultrasound NDT systems are also mainly used in bridge deck and tunnel surveys3,4, since they are limited to inspection of local areas due to the surface coupling requirement. This limitation, however, is removed in the case of novel air-coupled ultrasound sensors.

In the RPB HealTec system, the high-resolution and high sampling rate uncooled IRT camera is employed for inspection of the structural condition of the top asphalt layers. This includes detection of surface defects and shallow subsurface delaminations as well as deviations in the asphalt material properties (e.g., density, trapped moisture) and changes in structure. The multichannel GPR control unit with an array of low- and high-frequency GPR antennas (0.9 GHz and 1.6 GHz) provides information on the pavement structure ensuring coverage of all subsurface asphalt layers.

Installed on a specially designed trolley, the GPR module is optimised for high-speed inspection for detection of subsurface defects such as delaminations between the layers, material deterioration regions and deep cracks, voids as well as changes in the pavement structural design. Furthermore, the use of ACU system with low frequency 75 kHz transducers is applied for sensitive profiling of the surface layer condition and identification of the variations in asphalt density.

Synchronised data acquisition is a prerequisite for sensor fusion. In the RPB HealTec system, it is based on the timestamp recording and trigger pulses from a distance measuring instrument (DMI). The GNSS/INS navigation systems and HD video are employed for high accuracy spatial mapping and referencing of the detected defect locations. All NDT modules are mounted on a trolley or onto camera holders that can be easily installed on a survey vehicle along with the other hardware components. The data acquisition software is designed to provide functionality for synchronised collection and storage of spatially referenced sensor data.

After a survey, the collected sensor data are exported into the post-processing software for analysis. The corresponding methodology involves automated processing of the individual sensor data streams for detection of critical deviations in the pavement subsurface features together with the extraction of layer thickness profile from the low and high frequency GPR scans.

In IRT data stream processing, an inverse projection transformation and extraction of a region of the pavement surface (e.g., 2.5m X 5m) is applied to every frame. Next, processing is applied for detection of local critical changes in pavement segregation. The GPR and ACU B-scans are split into segments (e.g., 100m length) and processed based on the trend deviation analysis method, which automatically detects and maps all deviations from the uniform layer structure considered to be “significant” and possibly indicating the presence of defects and changes in pavement structure. Spatial registration of multi-dimensional sensor data is based on the timestamp, GNSS/DMI reference point and the sensor positioning offset information.

The sensor fusion is performed at the decision level with respect to the presence of the detected deviations in surface and subsurface condition. The processed IRT frames are visualised along with the GPR “defect mask” mapped on the 2D reformatted road lane surface extracted from HDV.

The current position corresponding to the investigated IRT frame is shown on the GPR and ACU B-Scan segments together with the detected subsurface trend deviations and layer interfaces.

The report for an inspected road section includes the processed sensor data and the “defect mask” sensor fusion output together with the extracted global IRT segregation patterns and pavement structure profile. This decision-support information can be further used for the evaluation of the defect severity and extent and general assessment of the road quality condition required in the pavement maintenance planning.

The analysis of the sensor fusion results for the data acquired during the RPB HealTec field trials on the A22 Brenner Motorway, Italy showed that the combination of the sensor outputs (GPR and IRT, especially) provides significantly more information of the pavement subsurface condition than the individual sensors. In other words, these NDT sensors are complementary yet reinforce each other when a defect is present. For instance, the first example shows the sensor fusion output at the location of the transition between a bridge deck and pavement with the presence of multiple cracks, which were detected in all sensor data streams. The next example demonstrates that the presence of shallow subsurface delamination that was also successfully detected.

Moreover, the cross-referencing of the multi-dimensional sensor outputs should be used for verification of the “existence” of the detected defects in order to decrease the number of false positive alarms. For instance, while the GPR analysis is efficient for detection of subsurface defects such as delaminations between the layers and material/structural changes, IRT provides the global segregation 2D map for the entire lane, thus allowing assessment of the condition of the regions not covered by the GPR antennas.

IRT also visualises the pavement surface condition around the detected defects. The corresponding examples include delaminations close to the lane borderline, deteriorated joints, structural changes such as patching and overlays, local variations in the material properties (e.g., moisture, asphalt degradation), surface cracking and pothole defects.

*Dr Alena Uus is a research assistant within the Department of Electrical and Electronic Engineering at the City University, London

References:

1.) Standards for Highways, Design Manual for Roads and Bridges: Volume 7. Pavement Design and Maintenance. pdf %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Available here Visit www.standardsforhighways.co.uk false http://www.standardsforhighways.co.uk/dmrb/vol7/section3/hd2908.pdf false false %>

2.) SHRP 2 R06(D) project, Nondestructive Testing to Identify Delaminations between HMA Layers. %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Available here Visit apps website false http://apps.trb.org/cmsfeed/TRBNetProjectDisplay.asp?ProjectID=2563 false false %>

3.) SHRP 2 R06(A) project, Nondestructive Testing to Identify Concrete Bridge Deck Deterioration. %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Available here Visit apps website false http://apps.trb.org/cmsfeed/TRBNetProjectDisplay.asp?ProjectID=2558 false false %>

4.) SHRP 2 R06(G) project, High-Speed Nondestructive Testing Methods for Mapping Voids, Debonding, Delaminations, Moisture, and Other Defects Behind or Within Tunnel Linings. %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Available here Visit apps website false http://apps.trb.org/cmsfeed/TRBNetProjectDisplay.asp?ProjectID=2672 false false %>.

5.) FP7 EU RPB HealTec project. %$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Available here Visit blogs.city.ac.uk website false http://blogs.city.ac.uk/fp7-rpbhealtec/ false false %>.

There is a need for optimisation and development of UK highway survey methods that would provide comprehensive information on the surface and subsurface pavement condition and operate at traffic speed, which eliminates the requirement for lane closures.

Performance of non-destructive testing (NDT) methods commonly employed in pavement condition surveys can be potentially improved by the sensor fusion. Combination of multiple NDT sensors increases the amount of useful information provided to the surveyors. The advantage of this approach was already proven in the cases of integration of ground penetrating radar (GPR) with falling weight deflectometer (FWD) as well as HD (high definition) video cameras with laser profilometers in traditional survey systems1.

Recently, a series of research projects2,3,4 were carried out for comparative analysis of the effectiveness of various NDT techniques in detection of subsurface defects in pavement, bridge deck and tunnel linings including: GPR, ultrasound, infrared thermography (IRT), FWD, impact echo, etc.

Based on different physical phenomena, all these techniques have their own advantages and limitations regarding resolution, maximum penetration depth, noise-to-signal ratio, optimal speed, sensitivity to environmental conditions and other factors affecting interpretation of sensor data. Thus, integration of several of these methods can improve the validity of measurements from individual sensors. This will directly improve the accuracy of pavement condition assessment.

An NDT system based on integration of GRP, IRT and air-coupled ultrasound (ACU) sensors was developed under the EU FP7 %$Linker:

While GPR has been widely employed in pavement and highway infrastructure surveys for many years1,2,3,4 and constitutes the basis for the proposed integrated solution, the application of thermography and ultrasound in pavement inspection has considerable novelty2.

Specifically, IRT is primarily used in bridge deck inspection3,4 or segregation measurements in new HMA layers during construction. This is related to the fact that, in the case of pavement surveys, the procedure for distinguishing features of various subsurface defect types in thermal patterns is not direct and is highly sensitive to environmental and operational conditions.

Classical ultrasound NDT systems are also mainly used in bridge deck and tunnel surveys3,4, since they are limited to inspection of local areas due to the surface coupling requirement. This limitation, however, is removed in the case of novel air-coupled ultrasound sensors.

In the RPB HealTec system, the high-resolution and high sampling rate uncooled IRT camera is employed for inspection of the structural condition of the top asphalt layers. This includes detection of surface defects and shallow subsurface delaminations as well as deviations in the asphalt material properties (e.g., density, trapped moisture) and changes in structure. The multichannel GPR control unit with an array of low- and high-frequency GPR antennas (0.9 GHz and 1.6 GHz) provides information on the pavement structure ensuring coverage of all subsurface asphalt layers.

Installed on a specially designed trolley, the GPR module is optimised for high-speed inspection for detection of subsurface defects such as delaminations between the layers, material deterioration regions and deep cracks, voids as well as changes in the pavement structural design. Furthermore, the use of ACU system with low frequency 75 kHz transducers is applied for sensitive profiling of the surface layer condition and identification of the variations in asphalt density.

Synchronised data acquisition is a prerequisite for sensor fusion. In the RPB HealTec system, it is based on the timestamp recording and trigger pulses from a distance measuring instrument (DMI). The GNSS/INS navigation systems and HD video are employed for high accuracy spatial mapping and referencing of the detected defect locations. All NDT modules are mounted on a trolley or onto camera holders that can be easily installed on a survey vehicle along with the other hardware components. The data acquisition software is designed to provide functionality for synchronised collection and storage of spatially referenced sensor data.

After a survey, the collected sensor data are exported into the post-processing software for analysis. The corresponding methodology involves automated processing of the individual sensor data streams for detection of critical deviations in the pavement subsurface features together with the extraction of layer thickness profile from the low and high frequency GPR scans.

In IRT data stream processing, an inverse projection transformation and extraction of a region of the pavement surface (e.g., 2.5m X 5m) is applied to every frame. Next, processing is applied for detection of local critical changes in pavement segregation. The GPR and ACU B-scans are split into segments (e.g., 100m length) and processed based on the trend deviation analysis method, which automatically detects and maps all deviations from the uniform layer structure considered to be “significant” and possibly indicating the presence of defects and changes in pavement structure. Spatial registration of multi-dimensional sensor data is based on the timestamp, GNSS/DMI reference point and the sensor positioning offset information.

The sensor fusion is performed at the decision level with respect to the presence of the detected deviations in surface and subsurface condition. The processed IRT frames are visualised along with the GPR “defect mask” mapped on the 2D reformatted road lane surface extracted from HDV.

The current position corresponding to the investigated IRT frame is shown on the GPR and ACU B-Scan segments together with the detected subsurface trend deviations and layer interfaces.

The report for an inspected road section includes the processed sensor data and the “defect mask” sensor fusion output together with the extracted global IRT segregation patterns and pavement structure profile. This decision-support information can be further used for the evaluation of the defect severity and extent and general assessment of the road quality condition required in the pavement maintenance planning.

The analysis of the sensor fusion results for the data acquired during the RPB HealTec field trials on the A22 Brenner Motorway, Italy showed that the combination of the sensor outputs (GPR and IRT, especially) provides significantly more information of the pavement subsurface condition than the individual sensors. In other words, these NDT sensors are complementary yet reinforce each other when a defect is present. For instance, the first example shows the sensor fusion output at the location of the transition between a bridge deck and pavement with the presence of multiple cracks, which were detected in all sensor data streams. The next example demonstrates that the presence of shallow subsurface delamination that was also successfully detected.

Moreover, the cross-referencing of the multi-dimensional sensor outputs should be used for verification of the “existence” of the detected defects in order to decrease the number of false positive alarms. For instance, while the GPR analysis is efficient for detection of subsurface defects such as delaminations between the layers and material/structural changes, IRT provides the global segregation 2D map for the entire lane, thus allowing assessment of the condition of the regions not covered by the GPR antennas.

IRT also visualises the pavement surface condition around the detected defects. The corresponding examples include delaminations close to the lane borderline, deteriorated joints, structural changes such as patching and overlays, local variations in the material properties (e.g., moisture, asphalt degradation), surface cracking and pothole defects.

*Dr Alena Uus is a research assistant within the Department of Electrical and Electronic Engineering at the City University, London

References:

1.) Standards for Highways, Design Manual for Roads and Bridges: Volume 7. Pavement Design and Maintenance. pdf %$Linker:

2.) SHRP 2 R06(D) project, Nondestructive Testing to Identify Delaminations between HMA Layers. %$Linker:

3.) SHRP 2 R06(A) project, Nondestructive Testing to Identify Concrete Bridge Deck Deterioration. %$Linker:

4.) SHRP 2 R06(G) project, High-Speed Nondestructive Testing Methods for Mapping Voids, Debonding, Delaminations, Moisture, and Other Defects Behind or Within Tunnel Linings. %$Linker:

5.) FP7 EU RPB HealTec project. %$Linker: