A wide range of new asphalt pavers have been introduced during 2019. Manufacturers have developed larger as well as smaller machines, offering increased efficiency for contractors. Meanwhile, the latest machines also produce lower levels of emissions, while using less fuel at the same time as being more productive. Of note is that all the firms have taken steps to improve all-round visibility, whether by offering raised operating platforms or reducing obstructions to the front, rear and sides. Operating seats can also be swung over the sides of many of the larger machines on the market to improve the operator view.

For 2019 it is clear that small has been beautiful for many asphalt paver manufacturers. Ultra-compact machines are now available that can take the place of paving by hand, boosting quality and productivity.

One of the smallest and most compact has been developed by Ammann in the shape of its AFW150-2 model. This unit can be used for urban street repairs, paving cycle paths or pedestrian walkways for example. Its compact vibrating screed allows it to pave widths of just 250mm and it can be used for tasks such as paving asphalt in between tram tracks. Fully extended, the screed allows paving widths of 1.3m, while attachments can be bolted-on to take maximum paving width to 1.65m.

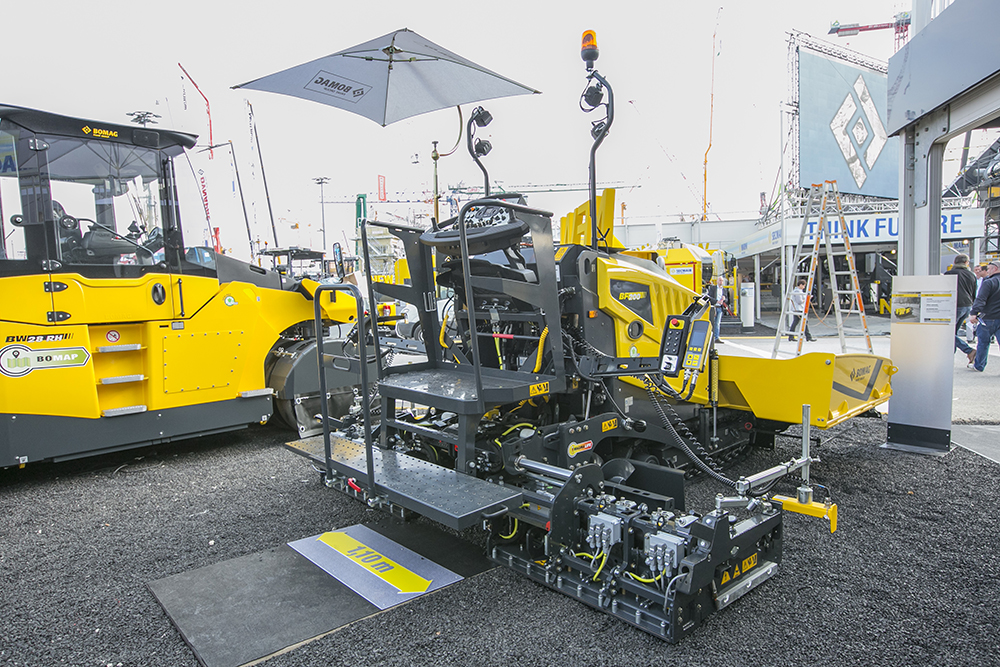

Also small and compact is the BF200 city paver from BOMAG. This 6tonne machine is powered by a 55.4kW diesel that meets the latest emissions requirements. As with other compact pavers it suits reinstatement and repair work in urban areas, as well as paving pedestrian walkways and cycle paths. The design of the hopper allows the wings to be retracted so it can be tracked through a 1.2m-wide doorway. Its tamper bar screed can be retracted so that it can pave between tram tracks, while maximum paving width is 3.4m.

US firm Carlson is best known for its vibration screeds but now offers a compact paver featuring a tamper bar screed. The new wheeled CP65 features 4x6 drive and has been developed for customers in Europe, as well as other international markets. The firm says that the screed features special bushes inside the extension system that can offset wear, while the design is also said to ensure optimum paving accuracy throughout its working life.

Carlson’s ECZ 34TV screed features hydraulic extension of 1.8-3.4m and a maximum paving width of 4.5m using bolt-on extensions. A minimum paving width of 750mm can be achieved. A vibratory-only variant of the screed, the ECZ34 V, is also available for North American customers on the basic CP60 paver with 2x6 drive. Both the ECZ34 TV and ECZ34 V screeds offer maximum paving thicknesses of 200mm. Power comes from a TCD 2.9litre L4 Deutz diesel rated at 55kW, with a Tier 4 Final/Stage V compliant version available, as well as a Tier 3 variant.

Dynapac says that its new F80W mini paver suits jobs such as reinstatement works, driveway or cycle lane construction. Said to be versatile, the paver allows high-quality paving in tight working areas. The machine is just 800mm wide and has a gas-heated V1300V vibrating screed that reaches working temperature in 15 minutes. Moving up slightly in size, the Dynapac F1200C and F1200CS models can be used for paving widths of 1.2-3.1m and can deliver up to 300tonnes/hour. The machines are driven by Deutz diesels that deliver 54kW. Customers can select versions of the engines meeting Tier 3 or Tier 4 Final emissions requirements. Customers can also choose between electric or gas heating for the screeds. The 5.8tonne F1200C has a choice of two screeds, but with vibration only. However, the 5.9tonne F1200CS has a choice of two screeds with tamper bar and vibration.

Vögele offers two machines in this ultra-compact class, the Super 700 and Super 800 paver. Deutz diesels delivering 55.4kW drive both models, with engine choices available to meet local emissions requirements. The Super 700 model is fitted with the AB 220V screed with vibration only and is aimed at North American customers, while the Super 800 features the AB220 TV screed with a tamper bar and vibration. Paving widths for both screeds range from 1.2-2.2m using hydraulic extension. Both screeds are available with bolt-on extensions allowing the AB 220 V to pave up to 3.2m wide and the AB 220 TV to pave up to 3.5m wide.

Volvo Construction Equipment (Volvo CE) has expanded its range with the addition of two pavers, the P2820D ABG and P2870D ABG. These are currently the most compact pavers in Volvo CE’s line-up and are designed for small-to-medium paving applications. The firm's P2820D ABG and P2870D ABG are quiet in operation and are suited to use in inner-city projects, such as cycle tracks and parking lots. Highly efficient, the new machines offer low fuel consumption and low CO² emissions. Power for both comes from 55kW Volvo engines and well-matched hydraulics. An option for customers comes in the shape of the more common dual conveyor or Volvo’s novel single conveyor. Other machine options include individually operated hopper wings, allowing the machines to pave closer to obstacles, as well as an electro-hydraulic foldable roof.

Rather larger is BOMAG’s BF700 paver, now benefiting from a totally revised control system, said to be a first in the market. This has its paver controls mounted on the arms of the operator’s seat, improving both control and ergonomics. The firm claims that the operator can sit more comfortably without having to hunch forward over a control panel, while the system also allows a better forward view over the hopper, an important feature for truck loading in particular.

Intended to boost paving efficiency, Dynapac now offers its MatTracker package. In addition, the firm has further optimised its DYN@link PORTAL system. The firm says that the Dyn@Link system allows a user to monitor its machines remotely from the office. It shows where the machines are located and if they are running. By adding an email address, the system will automatically notify the user when a machine enters or leaves a predefined area, providing an effective geo-fencing function. The firm says that the Dyn@Link system allows a user to monitor machines even when not logged in to the webpage.

Japanese firm Sumitomo is now hoping to boost its presence in Europe with the unveiling of its new HA60C-11 paver. Weighing in at 15tonnes the HA60C-11 is designed to combine productivity with a compact chassis, and it is only 2.5m wide. Power comes from a Yanmar diesel producing 110kW, which meets Stage V emissions requirements and allows paving speeds of 20m/min and travel speeds between working areas of up to 3km/h. The firm opted to use this engine to increase power over the 92kW of its earlier HA60C model.

The machine retains Sumitomo’s proven J-Paver 2360 screed, allowing paving widths from 2.3-6m without the need for any bolt-on attachments. The firm says it has upgraded the screed, making it more rugged and rigid and improving paving accuracy. According to Sumitomo, this new model is easy to use and it has a wide deck design. The twin seats can be swung over either side for better visibility of the screed edges. Other features include lower running costs and ease of maintenance, and the firm says that in the future it will be offering a version of the larger HA90 model which will feature many of the same upgrades.

Biggest of all the new pavers during 2019 has been the mighty SUPER 3000-3(i) paver from Vögele. The SUPER 3000-3(i) is the biggest asphalt paver in Vögele’s range and its updated design now allows it to pave widths up to 18m. The paver is designed primarily for new highway construction, as well as airport runway applications. Its huge screed means it is able to pave multiple highway lanes at the same time.

The SUPER 3000-3(i) is driven by a six-cylinder diesel rated at 354kW while the machine can deliver 1,800tonnes/hour of asphalt. The huge screed also allows the machine to lay asphalt to a maximum depth of 500mm.

Two screeds are offered for the SUPER 3000-3(i), the SB 300 or SB 350. Both are fixed units that can be fitted with hydraulically-adjustable ends, allowing 0-1.25m of extension on either side. The SB 300 screed replaces the earlier SB 250 and can also be used on the firm’s SUPER 1800-3(i), SUPER 1900-3(i) and SUPER 2100-3(i) pavers. The SB 350 has been designed specifically for use with the SUPER 3000-3(i). These tamper bar screeds benefit from a new system allowing an operator to change the stroke hydraulically to suit varied layer thicknesses. This is quicker and simpler than the conventional method of changing tamper stroke manually. The screeds also have an improved heating system that cuts warming up time from cold by 50%. In addition, set-up times for mounting the bolt-on extensions have been reduced.

A novel feature of the SUPER 3000-3(i) is the system allowing infinite height adjustment at the rear of the chassis. This is a key factor for paving thick asphalt layers, as the operator can ensure that the auger is not too deep in the asphalt, preventing material segregation.

As with other Vögele pavers, the SUPER 3000-3(i) features the firm’s sophisticated AutoSet Plus package that offers automated functions, The PaveDock Assistant communication system and VÖGELE EcoPlus low emissions package.

Another key innovation from Vögele is the option of the firm’s latest version of the WITOS package. This is now being offered as an option for the larger and more sophisticated pavers. The WITOS Paving Docu system allows for the automated documentation of onsite operations carried out with a paver. The firm says that this is a new software-based process-management solution.

The system comes in addition to the two options currently available from Vögele for recording and evaluating jobsite data. One is the RoadScan non-contacting temperature measurement package, which allows a site manager to monitor paving temperature. The other is the WITOS Paving Plus telematics solution, which allows the coordination and optimisation of processes between the mixing plant and paving operation. The simpler WITOS Paving Docu has been developed for contractors who want to record and evaluate data, in addition to the paving temperature. However, this does not have the full range of WITOS Paving Plus functions and process optimisation tools. The system also comes with a specially developed app.

The WITOS Paving Docu system means that site managers can initiate jobs directly on the job site without prior planning, recording all the paver and paving data. In addition, delivery notes can be scanned in using a QR code, or entered manually. At the end of each day’s operations, the system can send out automated jobsite reports. The app and pavers are networked using WLAN connectivity, allowing information to be transferred without a GSM connection.