India’s Eastern Peripheral Expressway project is one of the country's mega expressway road projects, cutting across three North Indian states - Partha Pratim Basistha recently visited the site

Huge numbers of construction machines as well as plant and equipment are working overtime, backed by mammoth manpower, to meet the targeted completion deadline of March 2018 for India’s Eastern Peripheral Expressway (EPE). The 135km arterial route is being built with six lanes and surrounds India’s National Capital, Delhi, its National Capital Region (NCR) and the industrially developed North Indian states of Haryana and Uttar Pradesh. Developed by the

The EPE will cut serious traffic snarls plaguing New Delhi’s roads. According to NHAI’s estimates, there are 8.85 million registered vehicles in Delhi. Out of this there are 52,000 commercial vehicles of which 40-50% are crossing Delhi. The colossal flow of traffic has taken pollution to unprecedented levels, which the EPE will help reduce.

Being touted as India’s first smart expressway, the EPE is being executed under the ‘Make in India’ campaign of India’s premier Narendra Modi. To ensure completion within the set deadline and bypass environmental hazards in the course of construction, the project is being directly monitored by India’s Supreme Court and the prime minister’s office. Sharing details of the project with

The 30m wide expressway features three lanes on both sides and runs from Kundli in Haryana on National Highway 1 (NH1). It crosses India’s historical Yamuna River and traverses State Highway-57, NH58, and NH24 near Dasna in Haryana, as well as NH91 near Beel Akbarpur. It will cut through the Taj Expressway, presently connecting Delhi and Agra in Uttar Pradesh, cross the Yamuna River once again and end at the NH2 in Palwal, Haryana. As the Western Peripheral Way is already complete, this will form a ring road around Delhi. Shape to the mammoth project is being given by five major Indian construction companies, appointed by the NHAI. They are, Sadbhav Engineering, Jaiprakash Associates, Ashoka Buildcon,

The contractors have been individually awarded six packages for executing the project. Under packages 1 and 2, Sadbhav is developing 21km and 24.5km of the expressway at an estimated cost of $122.65 million and $117.1 million respectively (INR 792 and 756 crores). Jaiprakash is constructing a 24.5km link at an estimated cost of $115.7 million (747 crores) under package 3. Ashoka Buildcon, has been awarded package 4, under which it is constructing 22km at a cost of $122.2 million (INR 789 crores). A 21km stretch is being developed by Oriental Structural within the entire stretch of 135km at a cost of $102.1 million (659 crores) under package 5. Gayatri is working under package 6, developing 22km of road costing $104.5 million (675 crores).

The firms are laying a 600mm-thick pavement, consisting of 150mm of granular sub-base (GSB), 150mm of dry lean concrete (DLC) and 300mm of pavement quality concrete (PQC). The GSB sub-base is 42m wide while the DLC is 38m wide and the PQC 30m wide to accommodate the six-lane expressway.

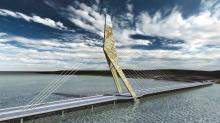

The contractors are constructing four mega bridges, 45 minor bridges, five flyovers, nine interchanges, eight rail over bridges (ROB), 76 vehicular underpasses (VUP), 151 pedestrian underpasses (PUP) and 109 culverts. The other impressive figures are for the colossal volumes of raw materials that contractors are sourcing. This includes 9.8 million tonnes of cement, 88,399 million tonnes of heat-treated steel, 44.2 million tonnes of aggregates and 17.82 million tonnes of manufactured sand.

Not to forget, 45 million m3 of earth is being sourced from villages close to the project, while large volumes of thermal fly ash are being procured from coal-fired power plants, located within 100km of the site. Fly ash is being used extensively in the project, based on requirements from the Supreme Court to minimise the environmental impact, as well as adding durability and strength to the concrete.

With the scope of the construction being quite wide across the individual packages, contractors are using varied construction methods. Under package 1, for constructing a 12,605m bridge with 21 precast concrete segments over the Yamuna River, a special foundation process has been adopted by Sadbhav. Each precast segment, weighing 100tonnes, is cast at the company’s yard nearby. Girder launchers are being used to lift the sections. The single grade separator/interchange on the Delhi Saharanpur highway in Uttar Pradesh is also a major project for Sadbhav. This stretches a total length of 16km and the separator is being supported by a total of 54 piles, each 1m in diameter and to a depth of 23m. The interchange will feature girders weighing from 55-60tonnes having a centre to centre span of 40.18m.

“Piling for ROBs, followed by the erection of the girders, is one of the major challenging tasks in the whole projects. This is because most of the ROBs, with wide spans, are for existing busy corridors on Indian Railways between Delhi and other states,” said Nanda Dulal Talukdar, general manager, Quality Control, Sadbhav Engineering.

Under package 1, Sadbhav is constructing one ROB with a total span of 70m, set up on 48 piles. Each piles is 1m in diameter to a depth of 23m. Two lattice boom crawler cranes will be used to erect composite steel girders for the ROB. Sadbhav is also building three ROBs and one grade separator under package 2. The three ROBs are on NH-25 on the Delhi-Meerut highway. Piling and erection are major tasks for the EPE project. This is because the project involves setting up numerous major and minor bridges, ROBs and interchanges. One of the major piling jobs is to support an 87m ROB being built by Ashoka Buildcon on the busy Barelli-Varanasi rail link in Uttar Pradesh.

Yogesh Tiwari, projects vice-president at Ashoka Buildcon said, “The ROB will have a total of 64 piles with diameters of 1.2m to depths of 22m. It will have 1000tonnes of composite steel girders, fabricated to the Research Design and Standards Organisations specifications from Indian Railways.” Ashoka Buildcon is constructing three grade separators, one ROB, 12 VUPs, 22 PUPs, four minor bridges and 20 box culverts. The VUPs measure 12m wide by 5.5m high while the PUPs are 7m wide by 3.5m high.

Gayatri Projects is constructing one 120m bridge on the Agra Canal with 98 piles to depths between 22-26m and 1.2m diameters. “There will be a total 100 PSC girders for the bridge, weighing 161-400tonnes. Being a critical route, the signalling and telecommunications and construction wing of the Indian Railways will be involved during the period of girder launching,” said AK Tripathi, senior project manager, Gayatri Projects. High levels of safety and quality are being observed on the project, such as for girder launching. Oriental has engaged Delhi-based girder launching and consulting agency, Bridgecon Infra Consultants. The company is providing assistance for the 600m bridge over the Yamuna River, which involves lifting 21 precast sections weighing between 90-120tonnes.

Raj Kapoor, senior project engineer at Oriental said, “The launching girder, including all its accessories has been fabricated with the drawings supplied by Bridgecon. Any items modified or rectified during assembly are reported for and final details is furnished to the consultant.”

The 152m launching girder for the Yamuna River project has a main box structure that rests on three supports, comprising the front, middle and rear support during the various stages of operation. There is large-scale involvement of specialised agencies in the project, both Indian and foreign, working for the client NHAI and as well as the contractors. NHAI’s engineer for the project is Scott & Wilson India, in joint venture with Consulting Engineers Group and in association with Aecom India.

Oriental has engaged B&SE Engineering Consultants as design consultant for its major bridge and permanent structures. The design consultant for the highway and other structures is Lea & Associates South Asia. Safety consultant of Oriental is Design Aid, while proof checking consultant is Construma.

Gayatri has outsourced fabrication and erection of the steel girders for the ROBs to Punjab-based Alliance Integrated Metaliks. For construction of the major bridges in packages 1 and 2, Sadbhav has subcontracted the work to Nagpur-based bridge specialist, Vijay Nirman. Fabrication and erection of the composite steel girders for Sadbhav’s three ROBs is being carried out by Vijay Nirman.

There is extensive involvement of piling specialists in the project. Piling foundation jobs for Sadbhav are being executed by Delhi-based Stongplant and Ayesha Construction.

Lalit Taneja, unit head of piling agency Auskini Infra Equip, also based in Delhi, said, “There is a major challenge to piling in the canals. Water flow is stopped for a minimal period by the state authorities as the canals serve the agrarian states of Uttar Pradesh and Haryana. We have deployed three rigs instead of two for piling the canals and ROB. This includes one Casagrande B170, one

Some 1,339 tipper trucks, mostly belonging to subcontractors, are working in shifts to move earth to the job sites. The trucks are also being used to transport DLC and boulders for crushing as well as aggregates to the batch mix plants. Close to 30 lattice crawler cranes are being used for well sinking jobs for the bridge piers, concrete pouring and also for general lifting.

In all, 12 weighbridges have been installed at the sites for weighing the tipper trucks carrying aggregates to the sites. And 202 excavators, mostly in the 20tonne class, from Tata

Most of the equipment has been acquired by contractors following careful evaluation of the project requirements.

“There are six

DK Mishra, deputy plant manager, Oriental explained that the pavers offer 16m maximum paving widths, allowing them to pave each of the 15m-wide, three-lane carriageways in a single pass. The pavers were acquired by Oriental from Jayprakash Associates, contractors for the Yamuna Expressway in 2011.

There are also four new

Sadbhav has put in place one Vögele Super 1800-3 paver, acquired in 2014, and one new Wirtgen SP 1600 slipform paver.

Gayatri purchased a Wirtgen SP 1600 paver along with new Case tandem rollers. All the pavers working at the EPE sites are fitted with

Oriental reconfiured one of its Kobelco SK 210 excavator to have an extended reach for use with compaction attachments to comply with NHAI’s strict compaction requirements for slopes on the carriageways. Meanwhile Sadbhav has five

26 batching plants are working on the EPE project across 12-hour shifts and these will deliver 2,730,000m3 of concrete for the project. Most of the batch mix plants are working on Sicoma’s or

Ashoka Buildcon is sourcing concrete for DLC and PQC from two 120m3/hr concrete batch mix plants from Linhoff India and from one 60m3/hr

Sharing details of the concrete plants working at the project, VG Sakthi Kumar, managing director, Schwing Stetter, Sales and Services India Private Limited said, “The contractors are using higher capacity batch mix plants and mobile batch mix plants.”

The EPE project will be one of India’s landmark infrastructure projects once complete. It is being monitored daily by the NHAI. Drone monitoring is also being carried out every month. With 68% of the work finished contractors have now placed an ambitious target to complete it by October 2017 to benefit from the bonus award from the client.