Simex says that its new RS 16 planer for creating rumble strips is an efficient alternative to costly specially designed machines or small manual equipment

Rumble strips created by intermittent milling of the wearing course offer the advantage of lower production costs and a higher durability than those made using elastoplastic adhesives - laminates. Compared to adhesives, rumble strips created by surface milling also have the important advantage of being indented and not raised, a characteristic that av

Rumble on: the new RS 16 strip planer from Simex

Simex says that its new RS 16 planer for creating rumble strips is an efficient alternative to costly specially designed machines or small manual equipment

Rumble strips created by intermittent milling of the wearing course offer the advantage of lower production costs and a higher durability than those made using elastoplastic adhesives - laminates. Compared to adhesives, rumble strips created by surface milling also have the important advantage of being indented and not raised, a characteristic that avoids accidental removal or damage by snowplows.

The idea for the new1141 Simex RS 16 triple-use planer for rumble strip came after studying the market in North America where rumble strips are most common.

Equidistant indentations are made by self-propelled machines or specific machinery, but for contractors this can involve a substantial outlay of resources versus the amount of use to be had from the equipment. In some cases, these costly and often large machines can be used only to create rumble strips and not to perform regular milling or removal of surface markings. For that, a contractor often must buy three pieces of equipment.

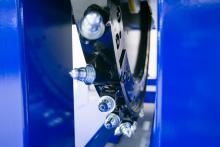

In search of a solution, Simex united three applications in one triple-use attachment which can be mounted on compact loaders or small front end loaders, either articulated or rigid. The full attachment consist of a planer fitted with a special enclosed support at front.

The system, by maintaining constant contact with the ground, allows the distance between the milled strips to be consistent, regardless of the advancement speed of the prime mover.

When intermittent milling is no longer necessary and the planer has to work in continuous mode, the front support is simply removed. By adjusting the width of the drum and modifying the mechanism that sets the distance between the strips, rumble strips can be milled to a depth and with variable spacing according to regulations in the countries where the equipment is to be used.

When used as a planer, the RS 16 has the same features as the PL 40.15, and as a result permits milling widths of up to 400mm and depths up to 150mm.

Similar to all SPL range planers, when fitted with appropriate teeth, the RS 16 can mill either asphalt or concrete pavement. It can also be quickly adapted to remove road surface markings or to level out roughness of the pavement.

With simple procedures, the drum can be replaced - the same drum being used in the previous two functions - with a multi-tooth drum for added versatility.

Rumble strips created by intermittent milling of the wearing course offer the advantage of lower production costs and a higher durability than those made using elastoplastic adhesives - laminates. Compared to adhesives, rumble strips created by surface milling also have the important advantage of being indented and not raised, a characteristic that avoids accidental removal or damage by snowplows.

The idea for the new

Equidistant indentations are made by self-propelled machines or specific machinery, but for contractors this can involve a substantial outlay of resources versus the amount of use to be had from the equipment. In some cases, these costly and often large machines can be used only to create rumble strips and not to perform regular milling or removal of surface markings. For that, a contractor often must buy three pieces of equipment.

In search of a solution, Simex united three applications in one triple-use attachment which can be mounted on compact loaders or small front end loaders, either articulated or rigid. The full attachment consist of a planer fitted with a special enclosed support at front.

The system, by maintaining constant contact with the ground, allows the distance between the milled strips to be consistent, regardless of the advancement speed of the prime mover.

When intermittent milling is no longer necessary and the planer has to work in continuous mode, the front support is simply removed. By adjusting the width of the drum and modifying the mechanism that sets the distance between the strips, rumble strips can be milled to a depth and with variable spacing according to regulations in the countries where the equipment is to be used.

When used as a planer, the RS 16 has the same features as the PL 40.15, and as a result permits milling widths of up to 400mm and depths up to 150mm.

Similar to all SPL range planers, when fitted with appropriate teeth, the RS 16 can mill either asphalt or concrete pavement. It can also be quickly adapted to remove road surface markings or to level out roughness of the pavement.

With simple procedures, the drum can be replaced - the same drum being used in the previous two functions - with a multi-tooth drum for added versatility.