Recent months have seen many major and vital road marking projects and products completed and tested in different parts of the world. Guy Woodford looks at some of them in Europe, North America, the Middle East and Africa. The London borough of Kensington and Chelsea now has one of the most dramatic streetscape designs in Europe. Exhibition Road’s striking chequered granite design, featuring a single surface running from South Kensington Station to Hyde Park and the full width of the road from building to b

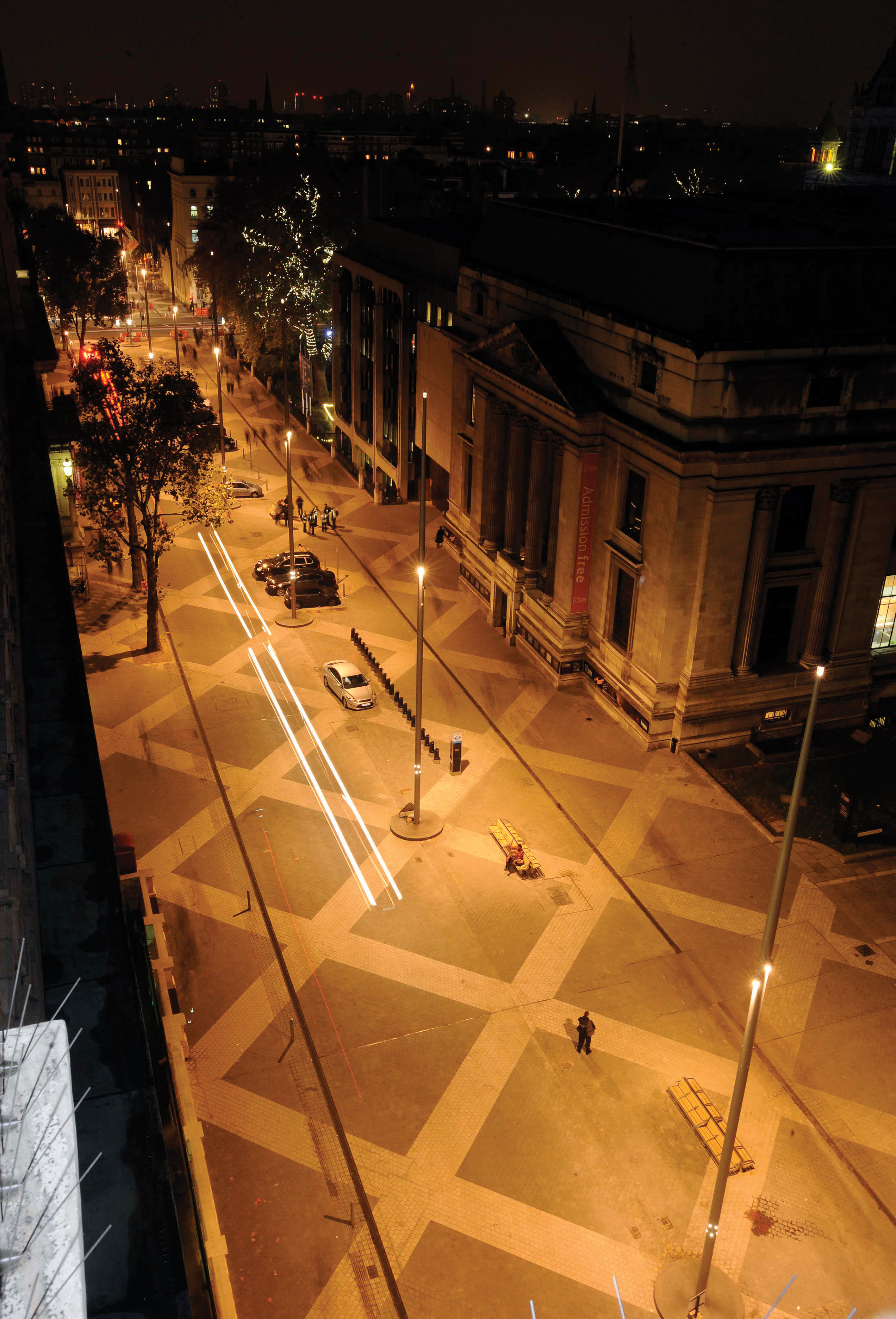

Exhibition Road, London. Now one of the most striking streetscapes in Europe

RSS

Exhibition Road’s striking chequered granite design, featuring a single surface running from South Kensington Station to Hyde Park and the full width of the road from building to building, took two years to create at a cost of US$44.39million. Kensington and Chelsea Borough Council (KCBC) contributed $22.34million;2387 Transport for London $20.51million; and Westminster City Council more than $1.5million.

In KCBC’s own words, Exhibition Road and South Kensington were “somewhat lacklustre” in streetscape terms, as well as cluttered and confusing to visitors and inhospitable to pedestrians. The local authority also admitted the pavements were too narrow for the 11 million people who visited the area each year.

Dixon Jones, an architect’s practice that had already been praised for its work on the Royal Opera House, Somerset House and the new wing of the National Portrait Gallery, won the competition to design the new Exhibition Road streetscape.1146 Balfour Beatty was chosen by KCBC to be the project’s contractor, and Schal was brought in as project management consultants.

Other key features of the streetscape design include black cast iron drainage channel covers, which run along each side of Exhibition Road and are around four metres from the respective building lines. Strips of corduroy tactile running alongside the drainage channels warn blind and partially sighted people that they are moving into or out of vehicle free zones. Meanwhile, sleek street lighting masts have been installed to showcase at night the impressive buildings of Exhibition Road.

The reopening of Exhibition Road on 8 December, 2011 was marked by a small ceremony to say thank you to the staff and craftspeople behind the revitalised streetscape. Local people and businesses that supported the project were also in attendance. Councillor Sir Merrick Cockell, leader of KCBC, believes the invigorated Exhibition Road streetscape, based on an initial idea in 2001, will lead to huge benefits for the borough, and London as a whole.

“It has taken us the best part of ten years to get here. But our great institutions finally have the setting they deserve,” he said. “For 2012 and far beyond, London now has a unique streetscape that will delight our many millions of visitors and which sets a new standard for urban design.”

Schal project manager Wayne Solman said: “The client is appreciative that we finished the project on time and within budget and recognises that our advice, management, programme and cost control was a significant factor in achieving that outcome.” Over in mainland Europe, Swiss manufacturer1285 Zehntner GmbH Testing Instruments has launched a new budget-priced retroreflectometer.

Equipped with the optics of the firm’s high selling ZRM 6014 retroreflectometer, the ZRM 6006 measures the night and day visibility of road markings at top speed. It provides reliable RL- and Qd-values in around two seconds, and indicates the ambient temperature and relative humidity.

The swift measurements of night and day visibility not only allow for efficient procedures but also increase the safety of the operator.

Zehntner claims the ZRM 6006 is simple to use, due to its solitary and large measuring button. The results are displayed in large digits on a bright transflective display which is optimally legible under all lighting conditions. The model also boasts a long battery life. Meanwhile, Denmark-based Delta has unveiled two new features for what it claims is the first mobile system for measuring retroreflection of road markings that offers the same accuracy as handheld instruments.

The overhead camera and Distance Measurement Instrument (DMI) options on the LTL-M mobile retroreflectometer have been added to the patent pending geometry correction system following its launch last year.

When placed on a vehicle windscreen, the overhead camera provides a driver’s eye HD video of the markings and the road. The video is stored for later viewing and can be displayed with an overlay of the actual measurement data.

The DMI is mounted on a vehicle’s wheels and provides accurate distance measurements, including on roads where GPS may fail due to lack of satellite contact.

Delta claim the LTL-M system is less cumbersome than handheld instruments, while being easy to mount, calibrate and operate. Customers on four continents have been using the system since its launch in 2011.

Sales to date, according to Delta, have been nearly double those forecasted which, it says, makes the company the leading global supplier of retroreflectometers for road markings and road signs.

Remaining in Denmark, Copenhagen city centre’s busy Øster Farimagsgade and Gothersgade junction has a new road marking system that allows cyclists to cycle through a green traffic light phase while, at the same time, reducing traffic congestion at a key crossing.

151 3i Innovation distributor 4012 Sagitar-Verkehrstechnik won approval from the city’s transport leaders for their idea of a bespoke system using inductive power that comprised flush-mounted LED on-road marking. German-based Sagitar assembled a package comprising of the iiiiLEVEL with an intelligent 24V power supply, which, it claimed, was affordable, versatile and durable.

The system is configured so that when travelling at a steady 20km/h, the cyclist will come to each set of lights during the green phase. The green LED road markers are installed at set distances of 7m and light up for a set time. A signal from the intelligent 3i power supply activates the lighting system after receiving an input signal from the traffic controller. As the cyclist rides along, a running green light indicates that by keeping up with the light, the rider will reach the next set of traffic lights during the green phase. Should these small LED lights turn off, cyclists know that they will not reach the next set of traffic lights during the green phase and can be slowing down accordingly, without risking a jump crossing on red. The innovative system allows speed and time intervals to be adjusted for preference.

The road marking system, completed in time for last year’s World Cycling Championship in Copenhagen, is set to be introduced at other busy traffic points in the Danish capital by spring 2012. Sagitar will soon be supplying another marking system from New Zealand-based 3i Innovation for a similar project in the northern Denmark city of Aalborg.

Meanwhile,173 Borum is finding its road marking machines and equipment in demand in South Africa and Iraq. Based in Pretoria in north-eastern South Africa, Lanino Traffic Markings recently purchased its second Borum machine, having been impressed with the performance and reliability of their first, bought in 2007.

The terrain the company works on ranges from remote and mountainous to flat plateaus containing busy highways, carrying up to 200,000 vehicles per day.

“You need a strong machine to work the mountain passes and the Borum 5000 is ideal,” said Lanino director Joos Joubert. “Also, because some of our jobs take us up to 1,000km from the office, a comfortable and reliable machine is a must.” Lanino also purchased the LineMaster, Borum’s on-board computer system. To help Lanino operators get acquainted with the new computer and machinery, Borum provided onsite training.

“We’re up to speed on the new features and we all know how to programme the computer,” explained Joubert. “It provides a range of valuable information, such as application rates and GPS coordinates. And its line cycle accuracy is impressive.”

In Iraq, first-time Borum customer Majeed Araim, managing director of Baghdad’s Future Contracting Company (FCC), has already recommended Borum machines to others in the Persian Gulf road marking industry.

With temperatures hitting 50°c in summer, sand storms and late night curfews, road marking in Baghdad can be euphemistically described as a challenge. To get the most out of cooler work periods available, Araim needed reliable, easy-to-use equipment. A Borum machine with LineMaster computer now heads FCCs fleet of road marking machines.

“The machine is performing well and is very versatile – and we work it hard,” said Araim. The lack of guaranteed security for foreign workers in Baghdad has made it unfeasible for Borum technicians to visit FCC. However, they are a phone call away, as Araim points out.

“At present, we refer to the manuals for detailed instructions and if we need assistance we call the Borum technician in the United Arab Emirates. But we hope to see a Borum trainer in Baghdad in the not too distant future to help us maximise our performance.”

The deployment of modern road marking technology in a far cooler climate has been taking place in the Eastern and Midwestern regions of the United States.

Two Koldspray airless spray system’s made by US-based4008 Dispensing Technology Corporation (DTC) were recently used by German firm 4009 Evonik to apply its 1659 Degaroute solvent-free methacrylate resin road markings.

Featuring an easily changeable disposable static mixing, the MMA 98:2 units’ skid mounted structures enable compatibility with standard pick-up trucks, and a 10.7m spray hose for stencil and short line applications. Koldspray is also said to come with off-the-shelf and easy-to-maintain parts, pressure compensated hydraulic pumps, and positive displacement fluid proportioning pumps. These attributes are said to provide ease of use and consistent application from project to project. Koldspray is also being used for demonstrations and projects involving American states and municipalities interested in improving road safety.

1658 Hofmann says its H25-4 self-propelled marking machine with articulated frame steering and front-wheel drive was used recently in Luxembourg. According to the German firm the machine, launched in mid-2011, is the first of its kind working in Airless method for one-component with cold paints, and for two-component with spray-proof cold plastics. In Luxembourg, the H25-4 is working in one-component method. The H25-4 has been sold with Hofmann’s Malcon4 electronic control system since the end of last year.

Meanwhile, Hofmann has sold its H18-1 airport marking machine to the British Army for use at a still to be decided UK air base. Another of its airport marking range, the H33-3, has been sold for use at Borispyl International Airport in Kiev, Ukraine, while another of the same model was due to be supplied to Abu Dhabi International Airport in the United Arab Emirates in February 2012. The company has also sold one of its H26-3 models for use at Otopeni Henri Coanda International Airport in Bucharest, Romania.

UK-based1394 Ennis Prismo has launched two new road marking products in recent months. Digimark is said to be an innovative surface graphics image system. It bonds to the road surface via a natural bitumen and is claimed to offer excellent adhesion. A layer of specially developed high strength fabric placed between the printed ink graphic and the adhesive binds them together. The fibre reinforcement controls the flexural rigidity and the extent of bond strength development to allow easy removal at the end of use. Digimark can be used for applications including warnings, delineation and advertising.

Paintmark is said to be a hard-wearing, temporary road marking solution which is applied by hand without the need for any heat. It is easily removed by hand leaving no residue on the road surface. It is available in a wide range of colours, symbols and lines.

Comprising three core elements, Paintmark’s trafficked surface is Ennis Prismo’s ‘High Build’ durable waterborne traffic paint, into which high index glass beads can be incorporated to provide appropriate levels of retro-reflectivity. Like Digimark, the system bonds to the road surface via a natural bitumen and possessing comparable adhesion.

Operators can remove Paintmark by warming it with a gas torch or steam hose. The need for hydroblasting, scabbling, or the use of a heat lance is removed, and no residue is left on the road surface. Ennis Prismo say Paintmark will be used in one of the showpiece sporting events of 2012. However, the company is still to release further details.

In December 2011, Ennis Prismo reached 500 days free from any reportable accident or injury at its main manufacturing plant in Chorley, Lancashire. The site primarily manufactures thermoplastic, bitumen-based crack sealants and bridge joints, as well as hot and cold applied anti-skid materials. The firm, which has clients across the UK, mainland Europe, the Middle East and Africa, claims its Lancashire factory is the most advanced thermoplastic production site in the world.

Meanwhile,2447 Geveko has been testing its thermoplastic road marking material Premark Vizispot which, the company says, provides night time visibility in both wet and dry conditions. After five winters at the firm’s Torfhaus test field in Germany, with an average daily traffic load of 8,000 vehicles, ViziSpot still reaches R4, RW2 and Q4 according to EN 1436. In addition, the preformed thermoplastic Premark Vizibility applied as Type 1 marking at the Torfhaus test field achieved R4, Q4 and S3 after five winters.

Geveko said ViziSpot and Vizibility showed minor snowplough damage, although snowploughs with steel blades had passed over the test field 1,484 times over the five-winter test period. The test field had also been salted 1,899 times over the course of those winters.

RSS

Recent months have seen many major and vital road marking projects and products completed and tested in different parts of the world. Guy Woodford looks at some of them in Europe, North America, the Middle East and Africa

The London borough of Kensington and Chelsea now has one of the most dramatic streetscape designs in Europe.Exhibition Road’s striking chequered granite design, featuring a single surface running from South Kensington Station to Hyde Park and the full width of the road from building to building, took two years to create at a cost of US$44.39million. Kensington and Chelsea Borough Council (KCBC) contributed $22.34million;

In KCBC’s own words, Exhibition Road and South Kensington were “somewhat lacklustre” in streetscape terms, as well as cluttered and confusing to visitors and inhospitable to pedestrians. The local authority also admitted the pavements were too narrow for the 11 million people who visited the area each year.

Dixon Jones, an architect’s practice that had already been praised for its work on the Royal Opera House, Somerset House and the new wing of the National Portrait Gallery, won the competition to design the new Exhibition Road streetscape.

Other key features of the streetscape design include black cast iron drainage channel covers, which run along each side of Exhibition Road and are around four metres from the respective building lines. Strips of corduroy tactile running alongside the drainage channels warn blind and partially sighted people that they are moving into or out of vehicle free zones. Meanwhile, sleek street lighting masts have been installed to showcase at night the impressive buildings of Exhibition Road.

The reopening of Exhibition Road on 8 December, 2011 was marked by a small ceremony to say thank you to the staff and craftspeople behind the revitalised streetscape. Local people and businesses that supported the project were also in attendance. Councillor Sir Merrick Cockell, leader of KCBC, believes the invigorated Exhibition Road streetscape, based on an initial idea in 2001, will lead to huge benefits for the borough, and London as a whole.

“It has taken us the best part of ten years to get here. But our great institutions finally have the setting they deserve,” he said. “For 2012 and far beyond, London now has a unique streetscape that will delight our many millions of visitors and which sets a new standard for urban design.”

Schal project manager Wayne Solman said: “The client is appreciative that we finished the project on time and within budget and recognises that our advice, management, programme and cost control was a significant factor in achieving that outcome.” Over in mainland Europe, Swiss manufacturer

Equipped with the optics of the firm’s high selling ZRM 6014 retroreflectometer, the ZRM 6006 measures the night and day visibility of road markings at top speed. It provides reliable RL- and Qd-values in around two seconds, and indicates the ambient temperature and relative humidity.

The swift measurements of night and day visibility not only allow for efficient procedures but also increase the safety of the operator.

Zehntner claims the ZRM 6006 is simple to use, due to its solitary and large measuring button. The results are displayed in large digits on a bright transflective display which is optimally legible under all lighting conditions. The model also boasts a long battery life. Meanwhile, Denmark-based Delta has unveiled two new features for what it claims is the first mobile system for measuring retroreflection of road markings that offers the same accuracy as handheld instruments.

The overhead camera and Distance Measurement Instrument (DMI) options on the LTL-M mobile retroreflectometer have been added to the patent pending geometry correction system following its launch last year.

When placed on a vehicle windscreen, the overhead camera provides a driver’s eye HD video of the markings and the road. The video is stored for later viewing and can be displayed with an overlay of the actual measurement data.

The DMI is mounted on a vehicle’s wheels and provides accurate distance measurements, including on roads where GPS may fail due to lack of satellite contact.

Delta claim the LTL-M system is less cumbersome than handheld instruments, while being easy to mount, calibrate and operate. Customers on four continents have been using the system since its launch in 2011.

Sales to date, according to Delta, have been nearly double those forecasted which, it says, makes the company the leading global supplier of retroreflectometers for road markings and road signs.

Remaining in Denmark, Copenhagen city centre’s busy Øster Farimagsgade and Gothersgade junction has a new road marking system that allows cyclists to cycle through a green traffic light phase while, at the same time, reducing traffic congestion at a key crossing.

The system is configured so that when travelling at a steady 20km/h, the cyclist will come to each set of lights during the green phase. The green LED road markers are installed at set distances of 7m and light up for a set time. A signal from the intelligent 3i power supply activates the lighting system after receiving an input signal from the traffic controller. As the cyclist rides along, a running green light indicates that by keeping up with the light, the rider will reach the next set of traffic lights during the green phase. Should these small LED lights turn off, cyclists know that they will not reach the next set of traffic lights during the green phase and can be slowing down accordingly, without risking a jump crossing on red. The innovative system allows speed and time intervals to be adjusted for preference.

The road marking system, completed in time for last year’s World Cycling Championship in Copenhagen, is set to be introduced at other busy traffic points in the Danish capital by spring 2012. Sagitar will soon be supplying another marking system from New Zealand-based 3i Innovation for a similar project in the northern Denmark city of Aalborg.

Meanwhile,

The terrain the company works on ranges from remote and mountainous to flat plateaus containing busy highways, carrying up to 200,000 vehicles per day.

“You need a strong machine to work the mountain passes and the Borum 5000 is ideal,” said Lanino director Joos Joubert. “Also, because some of our jobs take us up to 1,000km from the office, a comfortable and reliable machine is a must.” Lanino also purchased the LineMaster, Borum’s on-board computer system. To help Lanino operators get acquainted with the new computer and machinery, Borum provided onsite training.

“We’re up to speed on the new features and we all know how to programme the computer,” explained Joubert. “It provides a range of valuable information, such as application rates and GPS coordinates. And its line cycle accuracy is impressive.”

In Iraq, first-time Borum customer Majeed Araim, managing director of Baghdad’s Future Contracting Company (FCC), has already recommended Borum machines to others in the Persian Gulf road marking industry.

With temperatures hitting 50°c in summer, sand storms and late night curfews, road marking in Baghdad can be euphemistically described as a challenge. To get the most out of cooler work periods available, Araim needed reliable, easy-to-use equipment. A Borum machine with LineMaster computer now heads FCCs fleet of road marking machines.

“The machine is performing well and is very versatile – and we work it hard,” said Araim. The lack of guaranteed security for foreign workers in Baghdad has made it unfeasible for Borum technicians to visit FCC. However, they are a phone call away, as Araim points out.

“At present, we refer to the manuals for detailed instructions and if we need assistance we call the Borum technician in the United Arab Emirates. But we hope to see a Borum trainer in Baghdad in the not too distant future to help us maximise our performance.”

The deployment of modern road marking technology in a far cooler climate has been taking place in the Eastern and Midwestern regions of the United States.

Two Koldspray airless spray system’s made by US-based

Featuring an easily changeable disposable static mixing, the MMA 98:2 units’ skid mounted structures enable compatibility with standard pick-up trucks, and a 10.7m spray hose for stencil and short line applications. Koldspray is also said to come with off-the-shelf and easy-to-maintain parts, pressure compensated hydraulic pumps, and positive displacement fluid proportioning pumps. These attributes are said to provide ease of use and consistent application from project to project. Koldspray is also being used for demonstrations and projects involving American states and municipalities interested in improving road safety.

Meanwhile, Hofmann has sold its H18-1 airport marking machine to the British Army for use at a still to be decided UK air base. Another of its airport marking range, the H33-3, has been sold for use at Borispyl International Airport in Kiev, Ukraine, while another of the same model was due to be supplied to Abu Dhabi International Airport in the United Arab Emirates in February 2012. The company has also sold one of its H26-3 models for use at Otopeni Henri Coanda International Airport in Bucharest, Romania.

UK-based

Paintmark is said to be a hard-wearing, temporary road marking solution which is applied by hand without the need for any heat. It is easily removed by hand leaving no residue on the road surface. It is available in a wide range of colours, symbols and lines.

Comprising three core elements, Paintmark’s trafficked surface is Ennis Prismo’s ‘High Build’ durable waterborne traffic paint, into which high index glass beads can be incorporated to provide appropriate levels of retro-reflectivity. Like Digimark, the system bonds to the road surface via a natural bitumen and possessing comparable adhesion.

Operators can remove Paintmark by warming it with a gas torch or steam hose. The need for hydroblasting, scabbling, or the use of a heat lance is removed, and no residue is left on the road surface. Ennis Prismo say Paintmark will be used in one of the showpiece sporting events of 2012. However, the company is still to release further details.

In December 2011, Ennis Prismo reached 500 days free from any reportable accident or injury at its main manufacturing plant in Chorley, Lancashire. The site primarily manufactures thermoplastic, bitumen-based crack sealants and bridge joints, as well as hot and cold applied anti-skid materials. The firm, which has clients across the UK, mainland Europe, the Middle East and Africa, claims its Lancashire factory is the most advanced thermoplastic production site in the world.

Meanwhile,

Geveko said ViziSpot and Vizibility showed minor snowplough damage, although snowploughs with steel blades had passed over the test field 1,484 times over the five-winter test period. The test field had also been salted 1,899 times over the course of those winters.

RSS