When built it was determined that a vital US road/rail bridge would always be widened. Work on that huge project is going to plan as Patrick Smith reports

One of the biggest bridge widening projects in the world is being carried out under an ambitious development programme.

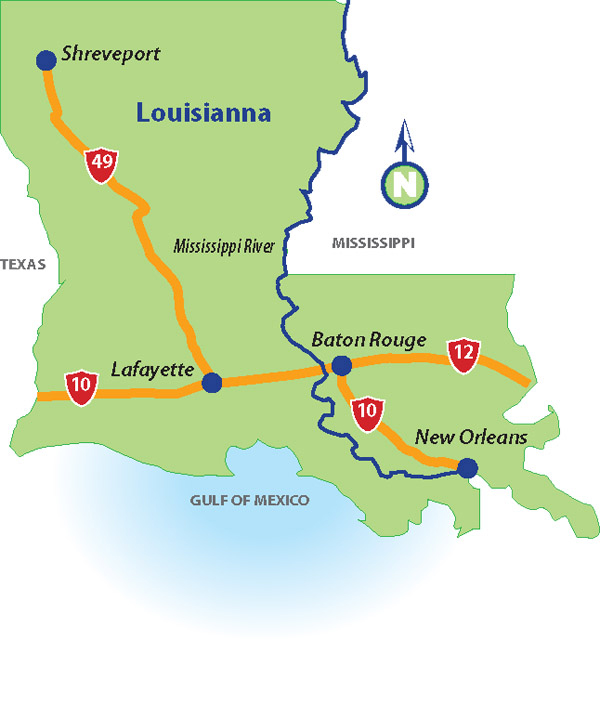

At US$1.2 billion, the seven-year scheme to widen the Huey P. Long Bridge in the US state of Louisiana is also the largest of 16 projects planned under the state's TIMED (Transportation Infrastructure Model for Economic Development) Programme at a cost of $5.2 billion.

The programme is designed to enhance economic development in the state through an investment in transportation projects.

Louisiana TIMED Managers (LTM, a joint venture between

Being constructed by Audubon Bridge Constructors (a joint venture of

The ambitious Huey P. Long road/ rail bridge project started in April 2006 and is the first change to the structure since it opened in 1935. [The bridge is named after the popular and notorious state governor who launched the state's first major roadway programme in 1929, and who was assassinated in September, 1935, three months before the bridge was completed].It was the first Mississippi River span built in Louisiana and the 29th along the length of the river, and is just upriver from the city of New Orleans. The New Orleans Public Belt Railroad owns the bridge with the Public Belt maintaining the railroad portion of the bridge and DOTD maintaining the roadway portion.

Because of these features and functionality, it was determined that the bridge would be widened instead of replaced when upgrades were needed.

In January 2010, the bridge was awarded the American Concrete Institute's Best Concrete Project Award, 2009 Highway and Bridge Projects Award of Excellence.

When completed in 2013 the cantilever truss bridge will have been expanded from two 2.74m lanes to three 3.35m lanes with a 0.6m inside shoulder and a 2.44m outside shoulder. It will also include new signalised intersections.

The road section, which carries four highway lanes of US 90, is 2,462m long with steep grades on both sides, while at 7,009m, the rail portion (two railroad tracks), which has a viaduct stretching well into the city, lays claim to being the longest and highest steel railroad bridge in the United States.

The Huey P. Long Bridge was completed in 1935, and the widest clean span is 240m long and is 41m above the water. There are three navigation channels below the bridge, the widest being 230m.

However, over five years after work started on the widening project, many agree that the phase involving the widening of the main bridge is the most visually exciting. It was also a complex and "rare technical feat." The first of three lifts was in June, 2010 when a massive bridge segment was lifted into place using multiple barges and strand jacks in what the contractor calls The Big Lift.Project description

The timeline of the project continues to be on track and two of the four phases have been completed.

•PHASE I: MAIN SUPPORT WIDENING (PIERS) In this phase, completed in May 2009, four river piers and one land pier were widened to support the additional lanes.

Contractor: Massman Construction Company.

•PHASE II: RAILROAD MODIFICATIONS In october 2006 work to relocate five selected railroad supports was done to facilitate the construction of the new approaches. work was completed in June, 2008.

Contractor: Boh Bros Construction Company.

•PHASE III: MAIN BRIDGE WIDENING (TRUSS) estimated to be completed in 2012, this phase will widen the existing truss on either side to accommodate new travel lanes and shoulders. Construction progress of this phase can be viewed by accessing two of six web cameras installed by hPl bridge Construction web Cameras.

Contractor: Massman Construction Company, Traylor Brothers and IHI joint venture.

•PHASE IV: NEW APPROACHES CONSTRUCTION during this phase of the project the two existing lanes will be widened to three lanes in each direction with shoulders and inside shoulders. the traffic circles at each end of the bridge will be replaced with signalised intersections. also, new roadway and elevated structures will be constructed.

ContraCtor: Peter Kiewit Sons, Massman Construction and Traylor Brothers joint venture.

The four-span bridge, which now serves as one of the three major Mississippi River crossings in the New Orleans metro area and which carries an average of 50,000 vehicles a day, kicked off its truss widening in November, 2009 with Span 1.

All three segments were installed using a span-by-span construction method. This involves preassembled span sections bigger than the size of a football field to be hoisted into position using strand jacks.

The first Big Lift required a 48-hour closure of the road, and railroad and river traffic movements were also restricted.

Due to the size and weight of the span segments, the lifts used were very rare, especially in bridge work.

The contractor responsible for the Big Lift and Phase III of the project is MTI, a joint venture of

When completed, the widened truss will allow the narrow bridge to have the three wider lanes along with the new inside and outside shoulders in each direction.

To carry out the first Big Lift, MTI hired HNTB Corporation, Kansas City, Missouri, to devise the span-by-span sequence.

Together, the two companies composed a methodical plan. First, a four-barge assembly connected by three sectional barges was prepared. On the completed barges, two large stability frames were assembled to help support the bridge span section during the lift. At the same time, lifting towers, which held the strand jacks, were installed on each side of Pier II and Pier III.

On the day prior to the first lift, the barges moved under the bridge following a well choreographed sequence. After being positioned at their intended location, the span section along with the stability frames were lifted approximately 41m using four 816.5tonne strand jacks.Once the span section was secured, the stability frames were lowered to the barges and the span section was slid in nearly 4m to its final position.

The hoisted span segment is 161m long and weighs 2,404tonnes. A lift of this size and scope is extremely uncommon in bridge building.

Steve Underwood, project manager with MTI, said: "It has taken a lot of coordination between the Coast Guard, New Orleans Public Belt Railroad and DOTD to make this lift happen." PB's Tim Todd, project engineer for Louisiana TIMED Managers, said: "A major challenge is coordinating construction efforts to minimise the effect on the public and the traffic that traverses the river." The $453 million contract to widen the truss is expected to be completed in 2012. By then, an estimated 15,876tonnes of structural steel and 750,000 new bolts will be used during this phase of the project.

Lift II was completed between 20-21 November, 2010.

A 2,402tonne truss, the second in the threepart series, was lifted 41m and attached in November, 2010. The lift of the 153.3m bridge segment was completed and the bridge and river reopened to traffic 11 hours ahead of the 48-hour schedule.

The third lift was completed on 9 April, 2011.

The contractors and team broke their own record when they lifted and skidded into place the third and final segment, a 161m long, 2,502tonne steel truss. That lift was completed in only 8.5 hours.

The third lift was the heaviest of the three.

The truss was lifted vertically 31m in 4.5 hours, and was skidded laterally nearly 4m in four hours and installed with pins in 2.5 hours.

The Mississippi River's main navigation channel was opened to marine traffic two hours ahead of schedule, rail traffic was disrupted only four hours instead of the eight that was scheduled and the bridge was reopened to automotive traffic 13 hours ahead of schedule.

Steve Underwood, MTI project manager was quoted in the 13 April, 2011 issue of Engineering News-Record as saying: "This lift went smoother and quicker because all systems performed well due to corrections and tweaks made from lessons learned during the first two lifts." The strand jacks were lifting at about 7m/ hour for the third and final lift. The strand jacks averaged 5m/hour on the previous two lifts.

According to John Brestin, HNTB project manager, the jacks were running a little faster for the second and third lifts because it was not quite as hot as it was in June, 2010 when the first lift occurred.RSS