Most hybrid solutions, as in the case of cars, combine an internal combustion engine with an electric motor. Hamm has instead combined an internal combustion engine with a hydraulic system for the tandem roller.

Although the maximum load is used regularly for compacting, it is always just for a few seconds at a time. This typically occurs when starting up or for activating the vibration or oscillation. All other compaction calls for significantly less power.

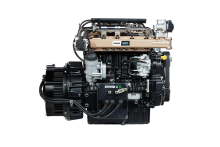

The new Hamm hybrid is equipped with a smaller diesel engine in combination with a hydraulic accumulator to satisfy the load peaks.

The hydraulic system works rather like a pumped storage power station: as soon as the power demand falls below the maximum load of the internal combustion engine, a pump fills the hydraulic accumulator. If a lot of power is called for, the hydraulic system functions as an auxiliary drive, able to supply a maximum short-term load of up to 20kW.

Following this the cycle begins afresh with refilling of the accumulator. Afterwards there is sufficient time to replenish the accumulator.

Hamm says that this technology allows the roller to deliver the same power but using a smaller diesel engine.

Two other components of the HD+ 90i PH also help to ease the load on the diesel engine: an efficiency-optimised electric fan drive and an efficient start-stop system.

This means that for the HD+ 90i PH an engine of just over 55kW suffices - instead of the 85kW unit in the conventional version.