Enhancing the sustainability of the pavements is of increasing importance as more transport agencies and municipalities around the world look to reduce their environmental impact. Recent innovations have demonstrated that the bitumen and the asphalt industry can adopt sustainable measures that both improve performance and reduce cost in the long run.

Sripath’s sustainability claims are backed by third-party validated studies detailed in environmental product declarations (EPDs) and sustainability reports. The following reports are available on Sripath’s website:

- ReLIXER: an asphalt rejuvenator or recycling agent;

- PGXpand: a bitumen-friendly polymeric-additive;

- NuMIXER: a green bio-oil bitumen softener or modifier.

Developing these EPDs and sustainability reports was a pivotal focus for the company’s leadership. The team sought to quantify a product’s impact on sustainability through independent verification. Exploring the lifecycle of each product, the EPDs detail resource and energy use as well as the impact on emissions. Using a cradle-to-gate approach, each EPD enumerates the product’s carbon footprint, including raw material source (A1), raw material transport (A2), manufacturing (A3) and transportation of final product (A4).

The entire Life Cycle Assessment project was managed by Geovitia, based in Chester, UK. The EPDs were authored by Solid Forest, headquartered in Madrid, Spain, and certified by The Environmental Footprint Institute, also in Madrid. Sripath is now leading the way in freely sharing its EPDs and sustainability reports on its website.

CARBON SEQUESTRATION ANALYSIS

As part of its sustainability efforts, certain Sripath products, such as ReLIXER and NuMIXER, are manufactured by blending bio-based oils, extracted from cultivated crops. As the crops grow, the plants capture carbon dioxide from the air and convert it into food and nutrients via photosynthesis. Such captured carbon units are retained within the extracted oil and become an integral part of the product. When such products are used as additives to modify bitumen or in asphalt mixes, they are eventually captured within roadway pavements. The carbon units from these products remain sequestered within the road pavement for the life and reuse of the asphalt pavement.

Sripath conducted a comprehensive carbon sequestration (S1) analysis for its bio-based products ReLIXER and NuMIXER. The analysis was based on the ILCD 3.1 methodology as required by the European Commission and the Type I Environmental Declarations outlined in ISO 14025:2010.

The carbon sequestration impact values were calculated and reported on a 1kg of product basis. Although not part of the EPD certification process, this analysis provides valuable insight into the impact of carbon capture and sequestration during biogenesis.

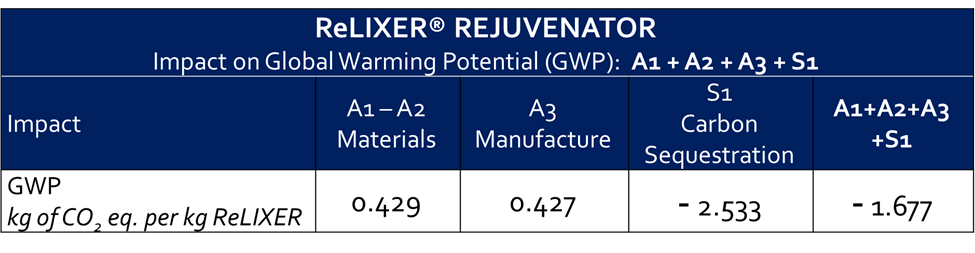

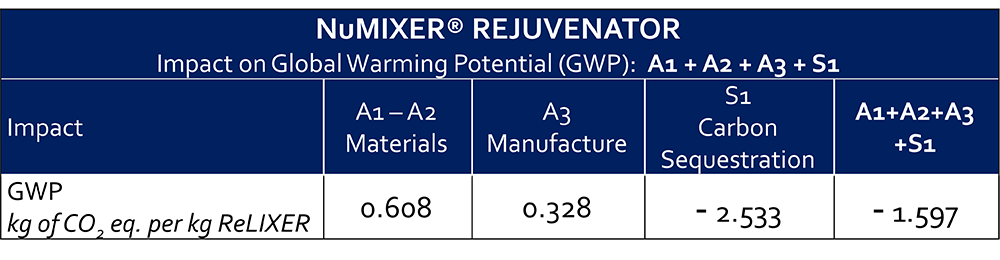

As an example, the global warming potential (GWP) results from both the EPD project and the carbon sequestration analysis for ReLIXER are summarised in table 1. The table shows a GWP value of -2.533kg of CO₂ equivalent per kilogram of ReLIXER, due to carbon sequestration (S1) and a total GWP value of -1.677kg of CO₂ equivalent per kilogram of ReLIXER for the A1+A2+A3+S1 parameter.

INCREASING RAP USE

Sripath has been a pioneer in promoting the use of high levels of reclaimed asphalt pavement (RAP) for paving applications.

Table 1: Global warming potential for ReLIXER

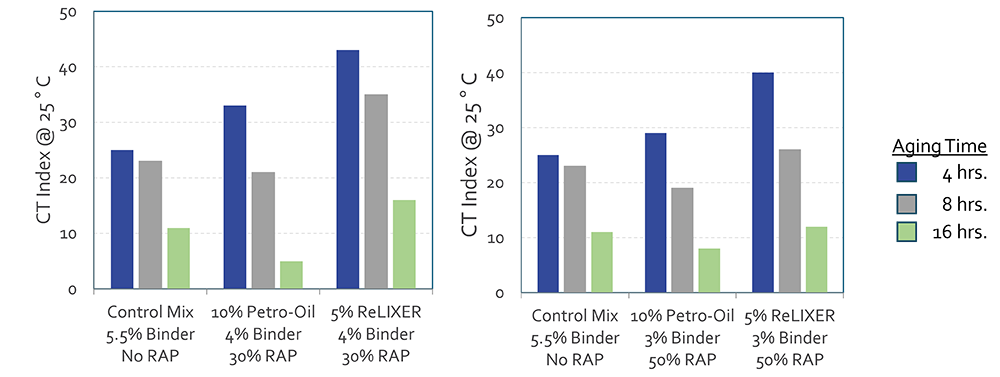

Figure 2: IDEAL CT index of aged high-RAP mixes dosed with rejuvenators

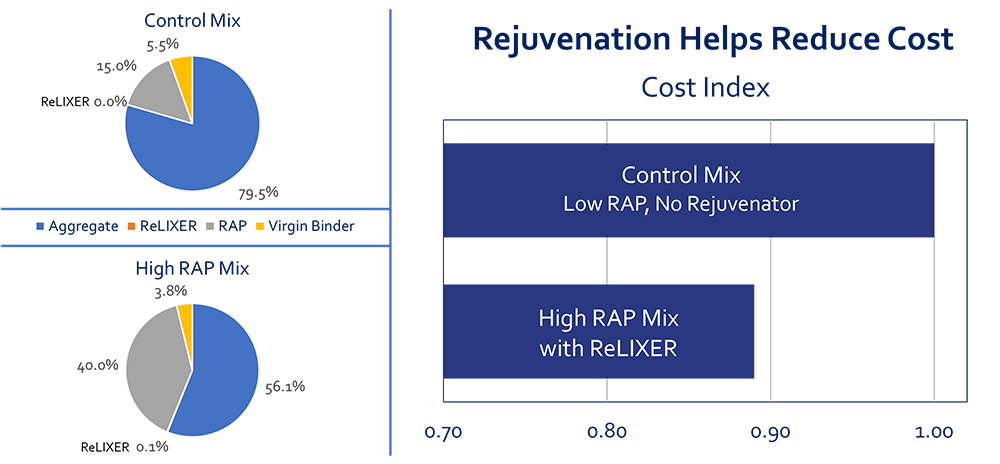

Figure 3: Impact of high-RAP mixes dosed with ReLIXER and the resulting costs

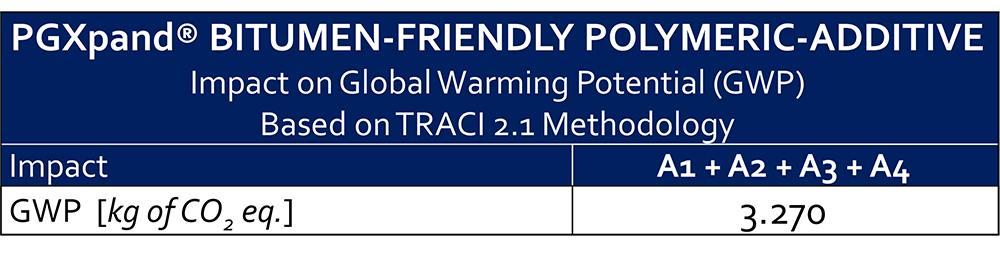

Table 2: Global warming potential for PGXpand

Globally, over 750 million tonnes of RAP are generated each year. Transportation agencies and industry leaders around the world are looking for ways to recycle and reuse higher levels of RAP in asphalt mixes.

More than a decade ago, as the industry looked for ways to use high-RAP mixes on roadways, the team at Sripath recognised the need for an effective rejuvenator that could restore the functional properties of aged bitumen in RAP.

An effective recycling agent allows for higher levels of RAP to be incorporated into asphalt mixes, rejuvenating the aged RAP binder. This reduces the amount of virgin binder needed and delivers roadways with desired performance and durability - while reducing the overall cost of the mix.

HIGH-RAP MIXES

Sripath’s ReLIXER, an eco-friendly asphalt rejuvenator or recycling agent, is a blend of bio-based oils designed to rejuvenate aged binder in RAP. The benefits of high levels of RAP go beyond the cost savings achieved through repurposing waste materials. High-RAP mixes - over 25% and up to 100% in some cases - require a rejuvenator to restore the functional properties of the aged RAP binder.

High-RAP mixes are typically designed using the balanced mix design concept, balancing rutting resistance against fracture-toughness properties. As an example, the IDEAL CT Index was evaluated as a measure of fracture toughness after oven-ageing of mixes containing 0%, 30% or 50% RAP. These high-RAP mixes were dosed with either 5% ReLIXER or 10% petrochemical oil. Samples were subject to loose-mix oven ageing for four, eight or 16 hours.

As seen in Figure 2, for both the 30% and 50% RAP, the mixes dosed with ReLIXER showed superior fracture toughness compared to mixes dosed with the petrochemical oil rejuvenator. Remarkably, the high-RAP ReLIXER mixes performed on a par with no-RAP mixes, especially after the ageing regimen. This demonstrates the ability of ReLIXER to restore the functional properties of aged bitumen to deliver durable roadways.

Contractors looking to be cost-conscious alongside their sustainability efforts find ReLIXER to be an effective rejuvenator. ReLIXER is effective at low dosage levels, helping to lower the costs of mixes by 5-15%. The need for minimal amounts of the additive is coupled with the ability to reduce the amount of virgin bitumen and aggregate needed, resulting in a reduction in the overall cost of the mix. The bottom line is that higher RAP mixes can also equate to lower overall cost while keeping sustainability at the forefront, all without compromising performance.

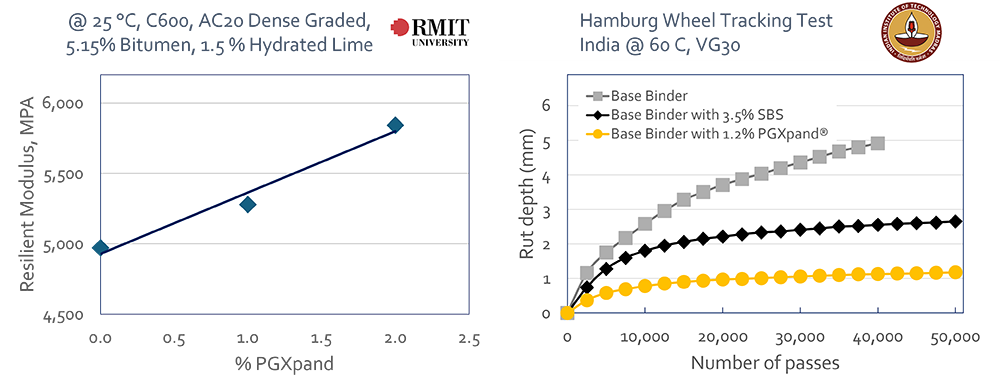

Figure 4: Impact of PGXpand on resilient modulus and rutting resistance

RELIXER AT WORK

ReLIXER stands out for being an environmentally friendly asphalt rejuvenator, delivering improved performance and durability. It relies on green industrial-grade bio-based oils that do not burden existing food sources. Environmental benefits of using high RAP mixes are also lauded by independent researchers. During a 2023 conference organised by the Institute of Asphalt Technology – Irish Branch, presenter William Wilson noted that using a high-RAP mix dosed with ReLIXER drastically lowered greenhouse gas emissions by 12-16%.

Independent testing by the Modified Asphalt Research Center at the University of Wisconsin in the US demonstrated that RAP samples with aged bitumen performed better in cracking-resistance testing compared to petrochemical oil rejuvenators as well as other bio-based oil rejuvenators. The test revealed ReLIXER to be most effective for as-paved performance and long-term roadway durability.

Practical applications of the rejuvenator have also demonstrated high-performance outcomes. An evaluation by S.T.A.T.E. Testing for the Illinois State Toll Highway Authority, also in the US, demonstrated superior performance for fracture toughness (544J/m² with 3.6% ReLIXER in mix) as compared to softer bitumen mixes without rejuvenator (435J/m²).

When it comes to the expectations for an effective asphalt rejuvenator like ReLIXER, the product should not only soften aged RAP bitumen to be workable but also provide for restored functional balance of properties, aid compaction and improve long-term durability. Added to this is the commitment to approaching these requirements with sustainable products and manufacturing processes that limit the impact on greenhouse gases.

SUSTAINABLE PMBs

Increased use of RAP is just one way the paving industry is looking to reduce its carbon footprint. Agencies continue to explore options for performance-enhancing products that create improved long-term outcomes for their projects. However, considering the drive toward sustainability, lower fuel consumption and energy expenditure during the manufacturing and paving processes are becoming pivotal as well.

Polymer modified bitumen (PMB) has been around for a long time. PMBs have traditionally performed an essential role in improving fatigue properties and rutting resistance. Additionally, PMBs can extend pavement life on roads that are subject to high wear and tear due to heavy traffic and extreme weather.

But not all PMBs are created equal. PMB produced using Sripath’s PGXpand - a bitumen-friendly polymeric-additive - helps deliver desired performance while being more environmentally friendly.

Unlike traditional elastomeric or plastomeric polymers, PGXpand enhances bitumen performance at high temperatures while retaining low-temperature properties. PGXpand can be blended into bitumen without the need for high temperatures, high-shear mixers and long mixing times.

As seen in table 2, PGXpand inherently has a lower carbon footprint, with a GWP of 3.27 for cradle-to-gate scope (A1 to A4). It is highly dosage-efficient, requiring almost half the amount of PGXpand as a traditional elastomer to achieve similar performance. Further, it helps eliminate or reduce the need for other additives such as crosslinkers and warm-mix additives. PGXpand also improves workability of the mix, helping reduce energy consumption during paving. Thus, PMBs based on PGXpand have a significantly reduced carbon footprint compared to traditional polymers.

As seen in Figure 4, a 2% addition of PGXpand can improve the resilient modulus by 15-20%. Also, an addition of 1.2% of PGXpand results in significantly improving the rutting resistance when compared to a mix made with a 3.5% SBS-based binder. Thus, PGXpand can deliver performance and be environmentally friendly at the same time.

ADJUSTING THE BITUMEN GRADE

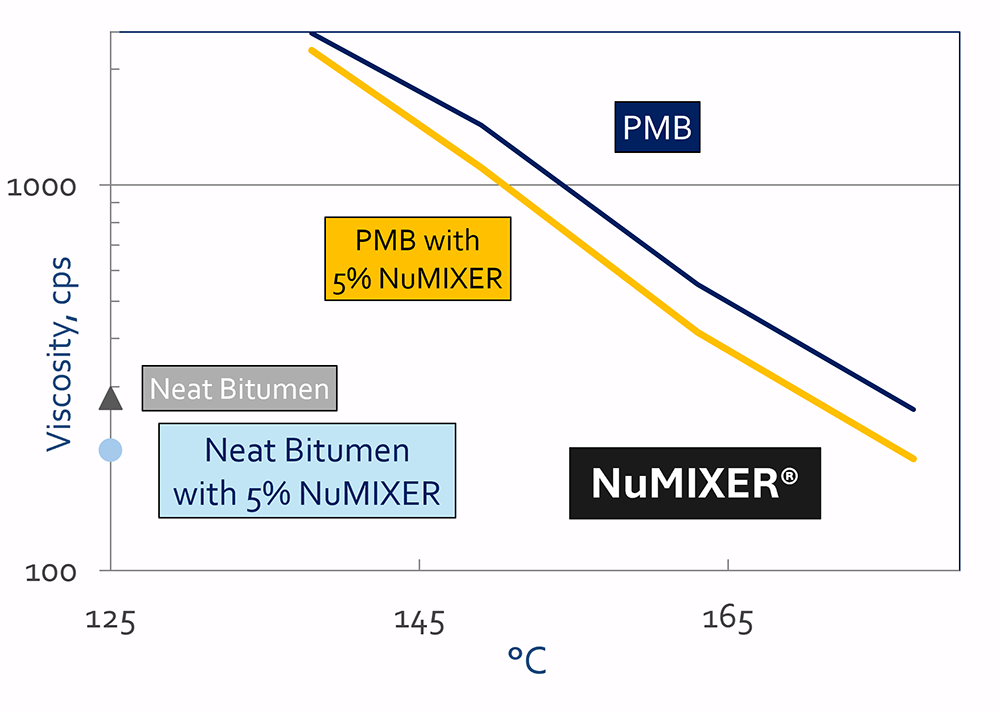

NuMIXER, another product in the Sripath line-up, is used to soften and adjust the grade of bitumen. It helps improve the low-temperature performance of bitumen. Notably, at low dosage levels, NuMIXER is effective in managing viscosity, enhancing low-temperature properties and improving fracture toughness and fatigue resistance.

While the intent was to develop a product to improve roadway cracking resistance, the Sripath research and development team kept sustainability at the forefront. The NuMIXER formula is a blend of prime bio-based oils that do not tax existing food sources. Analysis of the product’s GWP yielded a result of -1.59kg of CO₂ equivalent per kilogram of product.

Figure 5: Viscosity management using NuMIXER

Bitumen modification has been an essential aspect of paving for decades. NuMIXER is uniquely qualified in being both an effective binder modifier and an environmentally friendly solution. It delivers performance and helps reduce the carbon footprint.

Lowering energy consumption also calls to mind efforts to reduce energy use, both during the manufacture of the mix and the paving operation. Innovations in mix production have led to more widespread use of warm-mix additives in asphalt mixes. WMA technology allows mixes to be produced and paved at lower temperatures, which implies lower fuel and energy consumption and lower greenhouse gas emissions. Thus, WMA technology also provides an opportunity to reduce the carbon footprint and helps contractors meet their sustainability goals.

Table 3: Global warming potential for NuMIXER

OPTIMISING WITH KOOLTEQ

KoolTEQ, recently introduced by Sripath, is an environmentally friendly warm-mix additive that helps reduce production and paving temperatures of both hot asphalt and PMB mixes. It leverages the WMA technology without sacrificing performance and maintains long-term integrity of the pavement. It reduces mix-production temperatures and reduces paving temperature.

KoolTEQ is also dosage-efficient. Using just 0.25% KoolTEQ significantly improves compaction efficiency at paving temperatures as low as 115°C. This demonstrates superior effectiveness compared to many WMAs.

In addition to having a low carbon footprint as a product, KoolTEQ’s ability to lower the temperature requirements of WMA and its dosage efficiency directly helps lower the carbon footprint of the project itself. This reduction in energy consumption also helps lower costs of paving and permits transportation of mixes over larger distances before compaction.

Overall, the future of sustainable paving lies in responsible repurposing of recycled material and a reduced reliance on non-renewable energy and raw materials. Sripath’s products empower the paving industry to use sustainable additives.

*Deepak Madan is the chief marketing and business development officer at Sripath. He holds a PhD from the Rensselaer Polytechnic Institute in Troy in the US state of New York. He is also the recipient of the 2024 APMI Fellowship Award from the APMI, the American Powder Metallurgy Institute. Sripath is a global company, developing, manufacturing and marketing bitumen and asphalt additives.

*Deepak Madan is the chief marketing and business development officer at Sripath. He holds a PhD from the Rensselaer Polytechnic Institute in Troy in the US state of New York. He is also the recipient of the 2024 APMI Fellowship Award from the APMI, the American Powder Metallurgy Institute. Sripath is a global company, developing, manufacturing and marketing bitumen and asphalt additives.