Sustainability Targets in the Road Construction Sector

In 2015, the United Nations adopted the Agenda 2030. With the agenda, the global community aims not only to enable people on all continents to live a life in dignity but also to sustainably conserve vital natural resources. Economic, ecological, and social aspects all play a critical role in this. Governments around the world, civil society, and private enterprise are called upon to make a contribution to the realization of the Sustainable Development Goals set out in Agenda 2030.

Above and beyond such demands, the construction industry already faces specific on-site requirements with respect to the use of non-fossil fuels or the deployment of machines with local zero emissions – for instance, in the Nordic nations. In the light of this and their obligations to future generations, many leading players in the construction sector and numerous small and mid-size companies are currently setting their own goals to mitigate climate change.

Considerable effort on the part of all parties involved must be invested before the road construction industry as a whole can achieve the envisaged sustainability goals. This applies to machine manufacturers and the contractors who use their products. Given they share the same goals, both have a growing interest in developing and using machines that produce lower emissions in the course of their service life and are themselves manufactured with climate-friendly processes as well as construction methods that conserve valuable resources.

As a leading manufacturer of road construction machines, the Wirtgen Group has also set itself concrete goals to be realized over a number of steps. For example, Wirtgen, Vögele, Hamm, and Kleemann will further increase the availability of machines powered by hybrid or fully electric drive systems by 2026. In addition, all Wirtgen Group product brands, including Benninghoven, will offer machines and plants that can be operated with non-fossil or climate-neutral fuels. Last but not least, the digitalization of machines will make a significant contribution to process optimization and, in turn, lead to a further reduction of harmful emissions.

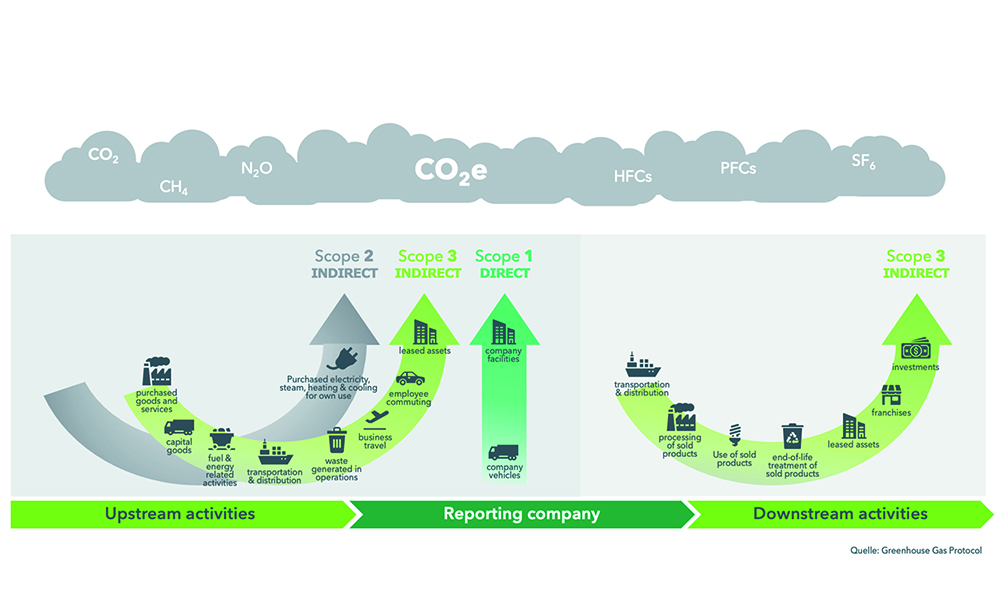

The Greenhouse Gas Protocol (GHG) has become globally established as a holistic accounting method for CO2e emissions. In a similar way to business accounting, it enables companies and institutions to systematically determine their emissions with harmful effects on the climate and to identify their sources.

The ultimate goal of all these measures is a considerable reduction of the carbon footprint of Wirtgen Group machines, plants, and systems by 2030. In concrete terms, the scope 1 and scope 2 emissions should be reduced by more than 50%. In the case of scope 3, the plans envisage a reduction in upstream and downstream emissions by at least 30%.

These primarily include the emissions from machines throughout their service life and, for example, emissions arising along the supply chain. To this end, John Deere, the parent company of the Wirtgen Group, has joined the Science Based Targets initiative (SBTi) and has had its own goals assessed and validated.

Holistic Approach

To realize the greatest possible reduction of overall emissions, it is essential that the efforts of all players along the road construction process chain are focused on the same. The key question is: “How can we construct or rehabilitate roads with minimal or zero climate-harmful emissions?”

To answer this question, not the emissions from individual machines or plants but rather the emissions of projects as a whole should be considered. In the same way as the fuel consumption of a vehicle is measured in miles per gallon, machine performance should be measured in units of work done – for example, per cubic meter of pavement material removed or per ton of asphalt paved. On construction sites, all factors must be taken into account to enable considerations based on kilometers of road constructed or rehabilitated. Such considerations indicate which construction method, materials, and machines are the climate-friendliest for each specific project.

The CECE is a pan-European organization representing construction machine manufacturers and related industries It has identified four areas in which CO2e emissions can be reduced:

• Machine efficiency:

Optimization of the power train, undercarriage, or hydraulic components leads to lower energy requirements without compromises in terms of performance.

• Operating efficiency:

Well-trained operating crews are essential for the efficient completion of construction projects. Just as much as semi-autonomous and autonomous systems, they help ensure that machines are used in an intelligent and also productive way.

• Process-efficiency:

Optimal interaction between all players on the construction site can make a big contribution to energy savings. This also includes the choice of the most appropriate machines and construction methods for every job and project.

• Alternative energy sources:

Instead of being powered by diesel, machines and equipment can use alternative fuels or be electrified to significantly reduce CO2e emissions.

When it comes to achieving a maximum reduction of CO2e emissions, a holistic approach that takes all aspects into consideration is essential. As the pan-European organization representing construction machine manufacturers and related industries, the CECE has already proposed a number of courses of action. Considerable savings potentials can be leveraged by further improvement of machine efficiency, improved construction processes and procedures, and more-efficient operating concepts. At the same time, alternative, non-fossil fuels and electric drive systems can play an important role on the road to climate neutrality.

Smart Assistance Systems and Alternative Energy Sources

In the past years, the Wirtgen Group has developed numerous solutions that have enabled significant reductions in fuel consumption. These include intelligently designed drive concepts and efficiency-optimized control systems. One example of this is Mill Assist from Wirtgen – an assistance system for cold milling machines that automatically delivers the performance and quality requirements entered by the machine operator and consistently guarantees the most favorable balance between milling performance and operating costs. This simultaneously reduces diesel fuel consumption and minimizes pick wear. Another example is the Dash 5 generation of road pavers from Vögele, which feature environmentally friendly machine technologies that also ensure lower fuel consumption.

Today, machines from Wirtgen, Vögele, Hamm, and Kleemann, equipped with engines that fulfill the requirements of US EPA Tier 4f respectively EU Stage V exhaust emission standards, can also be operated with alternative fuels. They are approved for use with alternative paraffinic fuels such as HVO (Hydrotreated Vegetable Oils – fuels based on vegetable oils or animal fats) or XtL fuels (X-to-Liquid – synthetic fuels on the basis of solid, liquid, or gaseous energy resources). There are already corresponding solutions for asphalt mixing plants from Benninghoven. These can be fueled with wood dust or BtL (Biomass-to-Liquid – liquid fuels derived from biomass).

The first battery-powered solutions are now also available, including the range of new mini pavers from Vögele and compact rollers from Hamm. These machines have sufficient battery capacity for a typical working day and deliver identical performance to their diesel-powered counterparts. For quite some time now, Kleemann has been offering crushers with direct electric drive systems for the processing of primary resources and recycling materials. These enable local zero emissions by means of connection to an external electric power supply.

CO2e Reduction Potential through Material Recycling

The holistic assessment of a construction site and the methods used necessitates a consideration not only of the emissions from individual machines and/or plant but also of all the emissions that arise or will arise in the production of the construction materials and mixes and in their transportation to, from, and on the construction site.

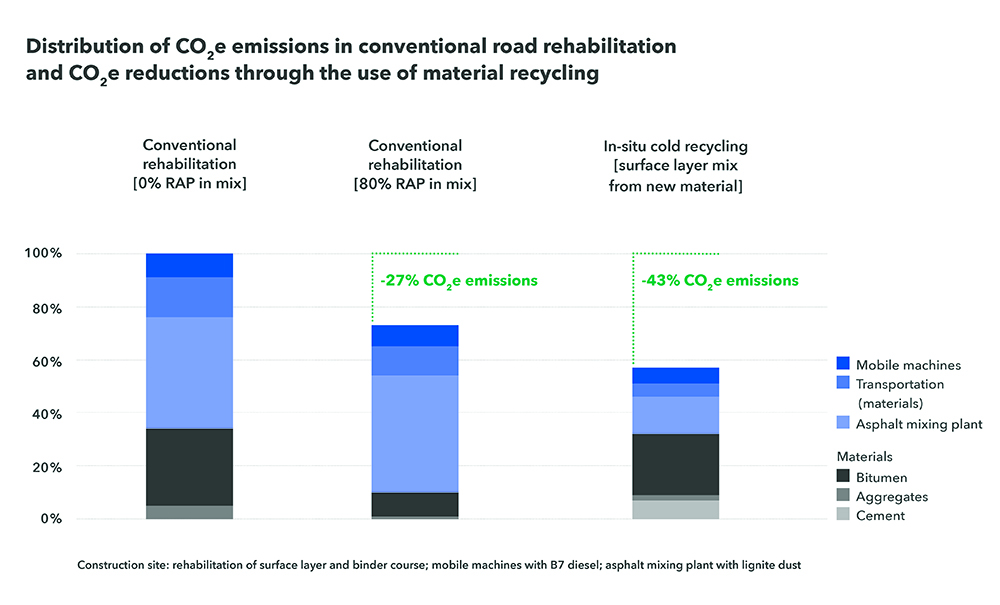

To illustrate the CO2e reduction potential through the use of recycling technologies, Fig.1 shows the emissions from a variety of construction methods used for the rehabilitation of the surface layer and binder course of a single-lane roadway. In all these cases, it has been assumed that the construction machines and transport vehicles use B7 diesel fuel and that the asphalt mixing plant is fueled by lignite dust. The transport distances reflect typical distances between mixing plants and construction sites.

The column on the left shows the emissions arising from a conventional approach: existing material is milled off and removed from the site before a new surface is paved with an asphalt mix produced from fresh material. Calculations of emissions show that the major proportion arises in the production of the asphalt mix and the materials this process requires.

The column in the middle shows the situation when the proportion of recycling material in the asphalt mix – i.e., reused milled material – amounts to 80%. Modern asphalt mixing plants can already produce such asphalt mixes , and appropriate Retrofit solutions are available for the upgrading of existing plants. This alone leads to a significant reduction in CO2e emissions of 27%.

Reductions are even greater if the construction materials are not heated before processing. The column on the left shows that this is where a major proportion of CO2e emissions arise. Proven alternatives are already in use around the globe. The most important of these are low-temperature asphalt production and cold recycling. With cold in-situ recycling, in particular, consumption of resources and transport movements are reduced by up to 90%. The scenario in our example shows a 43% reduction of CO2e emissions, column on the right, by using the cold recycling process, when a surface layer of asphalt mix produced from fresh materials is used over the cold recycled layer. In the case of full rehabilitation of the entire roadway, this construction method can reduce CO2e emissions by up to 60% – and without compromising quality. Further practical benefits of this method are faster project completion and longer-lasting roads.

Exploiting the Opportunities of Digitalization

Regardless of the measures employed, it is essential to have a transparent and verifiable system for determining and assessing emissions. This is where the tremendous opportunities offered by digitalization can play a decisive role. These days, for example, telematics systems are already able to register the fuel consumption of machines. For Wirtgen Group product brands alone, the number of machines fitted with such systems is aimed to rise to 42,000 by 2030. This will allow the documentation of such parameters under real-world operating conditions and will offer a much more realistic picture than predefined test cycles.

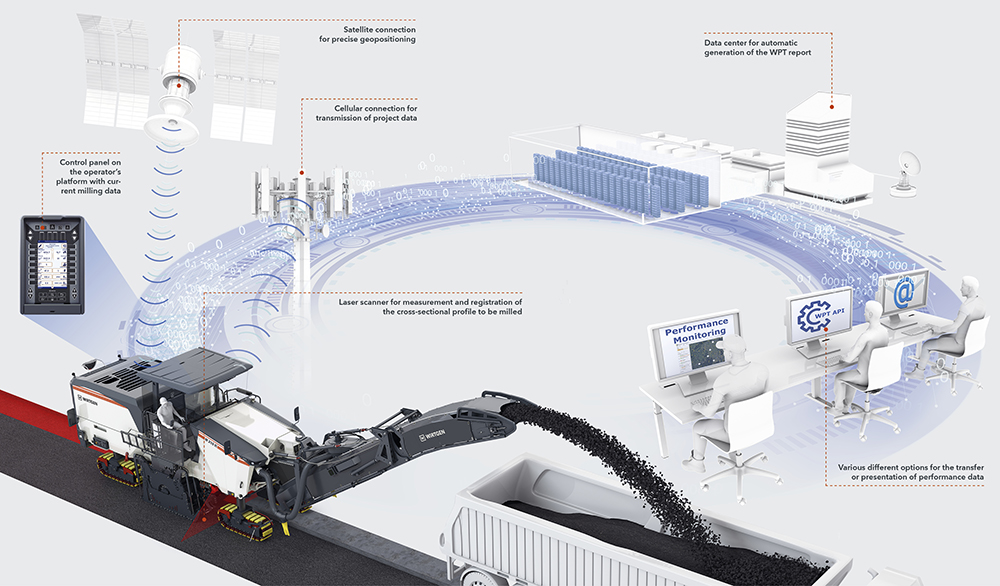

First systems for the documentation of the actual work performed are now also available. These include the Wirtgen Performance Tracker (WPT) for cold milling machines and wheeled recyclers/soil stabilizers (see Information Box). With the aid of such digital solutions, it will be possible to document consumption figures “per work done” – i.e., on a construction site or project basis.

The WPT for cold milling machines calculates and records how many cubic meters of asphalt have been milled. It can also, for instance, provide information on fuel consumption in the course of a specific construction project.

Summary

Around the world, the search is on for ways to mitigate climate change by means of a successive reduction of emissions of CO2 and other harmful gases (CO2e) to zero over the coming decades. To this end, construction machine manufacturers are pursuing a holistic approach in order to achieve the greatest possible reduction of CO2e emissions arising in the course of construction measures. The spectrum of measures and solutions required on the path to climate-friendly road construction extends from the optimization of machines, construction materials, and processes to new drive systems, alternative fuels, and the enormous opportunities offered by a digitalization of the overall construction process. A key tool on this path will be the calculation and documentation of the actual emissions produced. A holistic analysis and assessment of the emissions per unit of work done – expressed by the term “CO2e per work done”; e.g., per kilometer of road constructed or rehabilitated – offers the most promising approach for determining the most climate-friendly and resource-friendly construction methods.

Content produced in association with Wirtgen Group