Published on this website 14 August 2014

The creation of a new version of the world’s longest floating bridge in Seattle, in the US state of Washington, is among the world’s most eye-catching current bridge engineering projects. It is an impressive example of the health of the bridge replacement sector, particularly in the US, leaving it well placed for growth. Guy Woodford reports

Already the world’s longest floating bridge at over 2,310m long, the Governor Albert D Rosellini-Evergreen Point Floating Bridge in Seattle in the United States is getting a spectacular replacement structure after clocking up 50 years’ service.

Currently used by more than 70,000 vehicles daily to commute to work, school, and local recreational activities, the structure, commonly known as the State Route (SR) 520 floating bridge, faces earthquakes and windstorms. The four-lane bridge is also deemed unable to cope with the major population and employment growth in and around Seattle.

Due to open in spring 2016, the new US$751.4million SR 520 floating bridge is over 39m longer than its predecessor. It will carry six lanes of traffic as well as pedestrians and cyclists on a 4.26m-wide footpath. The new structure will rely on 77 concrete pontoons, compared to 33 for the original bridge. The longest pontoons measure 109m long, 22.86m wide and 8.53m tall.

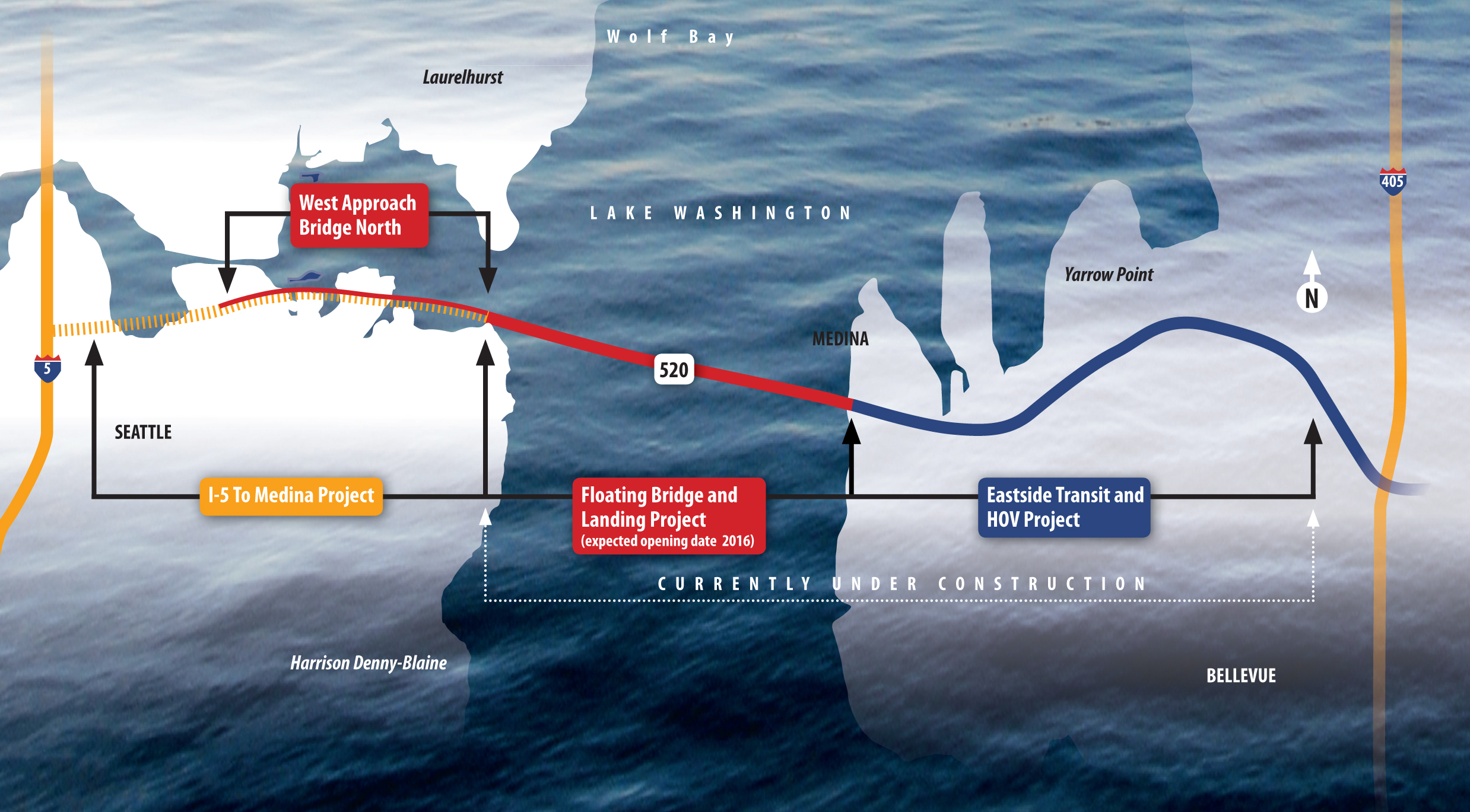

The SR 520 is one of only two highways across Lake Washington – a 35.4km (22mi)-long body of water separating Seattle from steadily growing cities east of the lake where

By 2040, the Puget Sound region’s population is expected to grow by more than 1.5 million and support an additional 1.2 million jobs. Forecasts predict that the population and employment growth will increase travel demand across SR 520 by 40,000 daily trips. The SR 520 Bridge Replacement and HOV Program is designed to ensure that this vital regional transport route can meet the needs of future population and employment growth.

Construction of the SR 520 floating bridge is owned and managed by the Washington State Department of Transportation (WSDOT), with Kiewit-General Joint Venture awarded the contract to build a casting facility in Aberdeen, Washington, and 33 of the 77 total pontoons needed for the structure. The building of the remaining 44 pontoons in Tacoma, Washington, their transport to Lake Washington, and the assembly of the new six-lane floating bridge is being carried out by Kiewit/General/Manson, a joint venture.

“Crews are using a variety of marine-based construction equipment to build the new bridge. This includes derrick cranes, lifting between 100-400tonnes; numerous barges and flexibarges that are modular and can be joined together; several full-time tugboats with two or more additional ocean tugs as needed; and 58 anchors installed to hold the new bridge in place,” said Dave Becher, project director for the WSDOT Floating Bridge and Landings Project, part of the agency’s broader SR 520 Bridge Replacement and HOV Program.

An interesting construction technique used by crews involved in the SR 520 floating bridge project could be found in their building of two cofferdams to support construction of two piers that support the eastern landing of the new bridge. Both cofferdams were constructed by installing large steel frames and then, using traditional driving technologies, sheet piles were vibrated and driven around the frames into the ground to create an enclosed space.

Construction of the first cofferdam (for Pier 2), on the shoreline in Medina, saw crews excavate the soil from within the fully enclosed structure, pumping the groundwater as required. The cofferdam was completed in August 2012 and removed after crews finished building the foundation for Pier 2. Construction of the second, in-lake cofferdam (for Pier 1), once fully enclosed, saw crews pump around 2.5 million gallons of water – nearly four Olympic-sized swimming pools worth – out of the area to create a work site that would otherwise have been under water. Once the cofferdam was drained, crews began construction of the footing and piers for the east approach bridge. The second cofferdam was completed in December 2012. Crews also built a coffer cell which provided a similar dry working environment.

Project crews have successfully dealt with a couple of unexpected problems to keep the build on track as Becher explained, “In May 2012, we discovered spalling and more-than-anticipated cracking in the endwalls in the first of six cycles of pontoons constructed in Aberdeen. We worked with the contractor and expert consultant, Ben C. Gerwick, Inc. (consulting firm hired by the contractor), to develop and approve a repair plan that will ensure the new floating bridge meets or exceeds the 75-year design life. Spalling issues were repaired in summer 2012, and the pontoons floated out of the casting basin on 30 July 2012.”

Becher said WSDOT also convened an expert review panel to determine the cause of and review repair procedures for concrete cracking, as developed by Ben C. Gerwick, Inc. The panel shared its findings in February 2013, recommending that WSDOT implement transverse post-tensioning on the longitudinal and cross pontoons.

“Transverse post-tensioning was implemented on the second cycle of pontoons that floated out of the basin on April 28 and 29 2013,” said Becher. “Transverse post-tensioning was later added to the four repaired cycle one pontoons.”

A variety of 3D modelling software has also been used to aid the development of the new floating bridge and its aesthetics. KPFF Consulting Engineers, the works’ lead design firm, used Revit, by

Meanwhile, structural and architectural models, such as SAP 2000 and Cinema4D, are said to have proved essential to designing a structure that will serve as an icon for the region. Furthermore, 3D programs to model construction sequences were an integral part of the construction planning process and have helped the contractor succeed on what is a highly complex project.

In one recent high profile new SR 520 floating bridge construction-related event that took place on Friday 27 June 2014, crews installed a large hinged transition span that connects the moveable, floating bridge to the stationary, elevated bridge segment near Lake Washington’s eastern shore. The transition span is composed of five steel girders, each 57.9m long and 40.82tonnes.

Summing up the future impact of the new SR 520 floating bridge, Becher said: “It will be a safer structure that is resistant to windstorms and includes two general-purpose lanes and one transit/HOV lane in each direction, wider and safer shoulders, a dedicated bicycle and pedestrian path, and the ability to accommodate future light rail if the region chooses to fund it.”

The SR 520 Bridge Replacement and HOV Program is one of the first programs in the US working to implement measurable sustainability criteria across an entire transport corridor. These criteria seek to improve the environmental, social, and economic welfare of communities affected by construction and operation of public infrastructure.

A project spokesperson said, “The current design enhances connectivity by improving connections between communities, increasing transit and HOV access, and improving access to public open space and to bicycle and pedestrian facilities. Specific examples of how we’re increasing connectivity include building landscaped lids connecting communities situated to the north and south of the corridor in Seattle and on the Eastside.

“The new floating bridge is also designed to accommodate light rail if the region chooses to fund it in the future.”

The spokesperson said the SR 520 Bridge Replacement and HOV Program is also developing the ‘Olmstedian vision’ of connected parks and greenways, and it will complete the regional shared-use bicycle and pedestrian path from the Eastside to Montlake and beyond, once the final build-out is complete.

Earthquake and windstorm-hit SR 520 floating bridge

The existing SR 520 floating bridge has experienced four significant earthquakes and windstorms since it was opened to the public in the summer of 1963. The notable earthquakes were the 1965 Seattle earthquake and the 2001 Nisqually earthquake, registering a magnitude of 6.7 and 6.8, respectively. Headline-grabbing windstorms were the 1993 Inauguration Day storm, when the bridge was closed to traffic for 13.5 hours, and the 2006 Hanukkah Eve storm, when the bridge was closed to traffic for 7.5 hours.

The existing bridge is closed to traffic and the drawspan is opened anytime wind gusts of 80.4kph (50mph) are sustained for 15 minutes or more.

During a typical windstorm, waves push broadside against the floating span, twisting and rocking the structure. Opening the drawspan relieves some of the stress on the bridge.

Why opt for a new SR 520 floating bridge over a fixed bridge?

Early on during project planning, WSDOT considered a range of options for crossing Lake Washington. Between 1997 and 1999, a 47-member stakeholder group evaluated a broad range of potential modes and routes for crossing Lake Washington. This stakeholder group’s Trans-Lake Washington Study examined over 100 concepts to improve mobility across and around Lake Washington, including car and passenger ferries, high-capacity transit options, demand management, and new lake crossings such as bridges and tunnels. These ideas were screened and the most promising were evaluated during the environmental review process.

Although a suspension (or fixed bridge) bridge would be the most likely alternate design option, it was eliminated from consideration for several reasons, most notably lake conditions, cost and size. The physical characteristics of Lake Washington create challenges for supporting a suspension bridge. These challenges include lake depth and an extremely soft lake bed. The lake is approximately 61m deep under the bridge. In addition, soft soils below the lake make it extremely expensive and difficult to construct the large towers required to support a suspension bridge. Please see the attached graphic for an illustration of the physical characteristics of Lake Washington.

Another cost-prohibitive factor of building a suspension bridge across Lake Washington is the length. The bridge would have to span over 2,286m (making it the longest suspension bridge in the world). The sheer size of the structure would have considerable impacts to views in the area. The bridge’s support towers would have to be approximately 192m tall, nearly the height of Seattle’s Space Needle, to support the bridge. These massive towers would be out of character with the surroundings, create more noise and block views. In addition, the two anchor piers required at the ends of the spans would be massive concrete supports.

For these reasons, WSDOT determined a floating bridge to be the best option for meeting the unique conditions of crossing Lake Washington.