There is massive development in design and construction of bridges in China and the Yingwuzhou Bridge over the Yangtze River is one key project – Mike Woof reports, with assistance from Route One’s Chinese publishing partner *CMTM

Called the Mother River, the Yangtze is a focal point for China politically, economically and culturally. The river has been at the heart of China’s development for millennia, its history stretching back as far as the dawn of human civilisation.The name Yangtze, or Yangzi, is itself a linguistic focus and derives from the local name for a stretch of the river close to Yangzhou, reflecting its cultural significance. And Yangzi comes from the name of a village and a historic ferry crossing, while Jiang is a Chinese word for river.

Geographically this long river is of massive importance as the Yangtze drains around 20% of China’s land area. Central to the country’s trade and transport, the river delta also accounts for some 20% of China’s GDP. And a centre for habitation, around one third of China’s population lives in the Yangtze River basin.

Originating in the Qinghai-Tibet Plain in the west of China, the Yangtze River winds its way through the country for some 6.300km and eventually flows into the Pacific Ocean at Shanghai. It is one of the world’s longest rivers and has remained an important trade route for China from historical times through to the present day.

But while the Yangtze River is crucial to China it also provides a transportation challenge for travellers to cross its waters. In years past this was achieved using ferries where the river was at its widest but with China’s vehicle numbers growing fast the need to span the river has grown enormously, particularly downstream where China’s economic activity remains focussed. Many bridges have been built to carry motor vehicles (as well as trains) and at present there are 65 spanning the Yangtze River, with another 19 bridges under construction.

Further upstream the bridges tend to be smaller but the closer the river flows to the Pacific Ocean, the larger the bridges have to be to cope with the increased width. The bridges towards the mouth of the Yangtze also tend to be larger structures in that China’s coastal area is more densely populated and as such, vehicle traffic levels tend to be considerably higher.

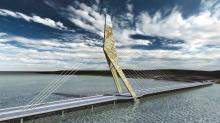

A number of the 19 structures currently under construction feature world-class engineering and of those, the Maanshan Highway Bridge and the Wuhan Yingwuzhou Bridge are of particular note. These two structures are the largest three-tower, four-span suspension bridges in the world and their size has required some innovative engineering solutions.

The new Yingwuzhou Bridge is being built to improve transport connections for the city of Wuhan, the capital of China’s economically important Hubei Province. This new structure is being built 2.3km upstream from the First Bridge over the Yangtze River, which was built in 1957 and carries four traffic lanes for vehicles on its upper deck as well as trains on its lower level. The 1.67km long First Bridge, also known as the Wuhan Yangtze River Bridge, features nine arches with a 1.156km central span and was constructed close to where the Han River tributary merges with the Yangtze. When the First Bridge was built it replaced ferry traffic over the Yangtze and is important historically as it provided the first direct link connecting northern and southern China’s roads and railways.

Wuhan is strategically placed in the middle of the navigable stretch of the Yangtze River in between Shanghai on the coast and Sichuan and Chongqing in the west. Its location made Wuhan a centre for commerce and transportation in China and the city grew out of the old town of Hankou, which became one of its districts.

Built at a key point, the bridge was erected where the Yangtze is narrower than in the rest of the Wuhan area and on the Hanyang side, the highway links with another structure spanning the Han River to Hankou. These two bridges have provided crucial connections between Wuhan’s Wuchang, Hankou and Hanyang districts, which focus on education, commerce and industry respectively. Further development of Wuhan resulted in the construction of two more structures with the second bridge opening in 1995 and the third (the Baishazhou Bridge) opening in 2000. But rapid traffic growth in the area, with some 6 million people living in the city and around 4 million in the surrounding metropolitan area, required the authorities to build an additional link.

The new Yingwuzhou Bridge will play a vital role in the continuing economic development of Wuhan and Hubei Province as a whole. The total cost of the bridge is around US$651 million (RMB 4 billion) and it is taking some 30 months to construct.

Building this structure has provided major engineering challenges as the area has suffered from earthquakes in the past, with the massive Wenchuan Earthquake having caused major damage in the city (although the landmark First bridge was not affected). With the river’s narrowest crossing points in the Wuhan area already spanned by existing bridges, the new structure is being constructed at a wider point and measures 7.8km, while its main central section is 2.1km long.

Design constraints were placed by the authorities and as the bridge is situated in the centre of the city, there was a need to restrict the height of the towers so as to preserve Wuhan’s landscape (and also so as not to restrict aircraft movements in the area).

This particular design requirement resulted in a three-tower suspension bridge configuration, with four-spans in all. The main spans are both 850m long and the bridge deck carries four lanes of traffic in either direction, with vehicles being allowed to drive at speeds of up to 60km/h once it is opened. This design has called for an innovative engineering approach and to balance out the loads from the two central spans, the main central tower has been constructed so as to offer a degree of elasticity.

To achieve this, the central tower features a novel composite steel-concrete construction that allows a certain amount of flex while also providing sufficient rigidity. It is worth noting too that the bridge structure has also been designed so as to cope with the massive additional loads resulting from earthquakes, given the risk from major tremors in the Wuhan area.

The 152m high central tower is constructed on a foundation that features no less than 39 bored piles, each 2.8m in diameter. The pile cap is oval in shape and measures 70×34m across and 6.5m thick. The bottom 45m section of this column is of concrete construction while the upper 107m of the tower is of steel. The heaviest single segment for the tower weighs 392.7tonnes and placing this required very heavy lifting gear, with a 1000tonne capacity floating crane being used for erection.

The other sections are also massive with the second largest segment tipping the scales at 200.8tonnes, requiring the use of the world’s largest horizontal-boom tower crane,

To handle this difficult project, China's premier bridge construction company was brought in as main contractor.

The construction schedule for the project is a challenge in itself due in part to the novel engineering being used. Some of the contractor’s methodology and equipment for the new Yingwuzhou Bridge had already been proven so as to ensure the techniques would allow this complex project to meet its construction deadlines.

Lifting the main sections of the bridge has been a particular challenge. China Railway Major Bridge Engineering Group first used the massive Zoomlion D5200 crane to complete the erection of 42 of the 230tonne by 183m long steel segments for another project, the Maanshan Yangtze River Highway Bridge. Once this work was complete the company transferred the Zoomlion D5200 tower crane to the site where the Wuhan Yingwuzhou Bridge was under construction.

Meanwhile at the site of the Wuhan Yingwuzhou Bridge, the contracting team poured concrete for the last segment of the number 2 tower, allowing erection of the upper steel section to commence on May 11th 2012. By May 14th 2012, the main structure of number 1 tower was completed and then on May 30th 2012, the open caissons for the north anchorage of the bridge were placed accurately. By June 9th 2012, the last T1 segment for the steel section of number 2 tower had been erected, a significant and complex step in the construction of the bridge. The T1 section features four components, each weighing close to 200tonnes, and located at the column’s four corners.

On July 10th 2012, the upper components for the number 3 tower for the bridge were installed and in August 2012, the D5200 tower crane was erected at the bridge site and began operations. The T3 segment was lifted into place on September 3rd 2012.

The left and right cable saddles for the south anchorage of the bridge were successfully erected on October 19th The innovative cable saddle design combines both casting and welding, and each component weighs in at 64tonnes.

)The main cables of the bridge disperse to single strands through the cable saddles and are then fixed inside the anchor chamber, allowing main cable to be connected with the anchorage mass. Successful installation of the cable saddle marked the commencement of the upper installation engineering works for the south anchorage of the bridge.

The number 10 segment of the upper steel section of the number 2 tower was lifted into place on October 27th 2012 and the south anchorage took shape on the 10th November 2012. The last upper beam for the number 2 tower of the Wuhan Yingwuzhou Yangtze River Bridge was placed on November 26th 2012.

Since the pile cap was constructed on January 17th, the project has run smoothly and work has progressed well, with the fifth segment having been installed by March 13th 2013.

The D5200 crane completed its duties ahead of schedule at the Wuhan Yingwuzhou Bridge and its operation has been noted as a key factor in the engineering team meeting the construction schedule so far.

After finishing erection of the main tower of Yingwuzhou Bridge, Zhou Zhimin, director of mechanical equipment department of Daqiaoju Company said, “The construction equipment was very important for the bridge construction. Use of D5200 tower crane has hugely improved construction efficiency and reduced project cost, and has become an integral part of our core competitiveness.”

*Note all images supplied courtesy of World Highways partner magazine in China CMTM (Construction Machinery Technology & Management)

Mighty crane

Zoomlion carried out the research and development work to produce the D5200 tower crane to meet a specific requirement from China Railway Major Bridge Engineering Group. The contractor realised it needed this large machine as it would provide the most efficient method of constructing key components for the Maanshan Yangtze River Bridge Project. This massive tower crane features a maximum load of 5,200tonne-metres, with a lifting height of 210m. Its lifting capacity is 250tonnes while it has a maximum working range of 50m and it features an upper turning structure.