Jason Hallett is currently Chief Executive Officer of Digital Construction Works (DCW), a joint venture formed in October 2019 between Bentley Systems and Topcon Positioning Group. DCW is focused on Digital Integration and Automation Services for Construction. Jason assumed the role of CEO in January 2022 after holding the position of Chief Operating Officer since the company’s inception. Prior to DCW, Jason served as Vice President of Global Software Business Development and Digital Construction at Topcon Positioning Systems, where Topcon had employed him since 2007. His career has been working in the surveying and construction industries for 34 years. Mr. Hallett’s primary responsibilities at Topcon included leading the MAGNET Systems business of Topcon and the Digital Construction initiatives related to the strategic digital co-venture partnership with Bentley Systems. While at Topcon, Mr. Hallett also held the position of Vice President of Global Product Management. He is a licensed California Professional Land Surveyor (since 1999), has been awarded multiple patents, holds a Certificate of Business Excellence from the Haas School of Business at U.C. Berkeley, holds a B.S. degree in Management, and holds an A.A. degree in Business.

Q: How would you sum up the immediate benefits of the tighter integration of construction operations that users will gain when using DCW services and technology? Tell us the key advantages that DCW brings…… and are there any early adopters you could mention that are finding success with DCW and the DCW Integrations Platform?

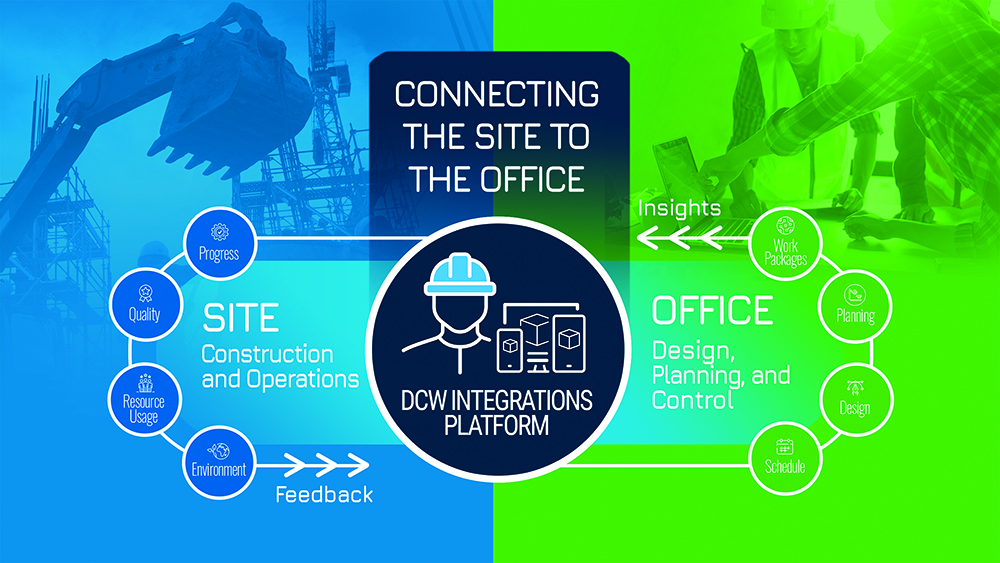

Jason: The primary value that we see is DCW greatly reduces the technical debt related to disconnected tools that result in manual handovers today. Our platform closes these technology gaps and automates the handovers through integrations that are tied to a digital workflow engine, which ultimately saves our clients’ time. It improves data fidelity and ensures that schedule deviations can be managed in near real-time.

As far as early adopters go, one case that we have just published online is a project we did with Mortenson Construction, where we integrated the 4D Model, and also integrated a material-tracking system called Jovix for use on their construction project to build the largest soccer stadium in the U.S. We were able to help them seamlessly integrate their applications to help manage their supply chain.

During the stadium construction, the Mortenson/Messer project team needed help solving a specific business problem around real-time visibility into critical path material fabrication, delivery, and installation. The Mortenson Sports and Entertainment Group field manager approached the Mortenson Innovator Group with a big problem, stating he had no visibility into critical path methods, particularly with steel in the supply chain. They wanted absolute certainty that they could be on schedule as planned.

![ The new GEODIS Park Soccer Stadium and Entertainment Fairgrounds in Nashville, TN, were built by Mortenson using DCW technologyThe new GEODIS Park Soccer Stadium and Entertainment Fairgrounds in Nashville, TN, were built by Mortenson using DCW technology [Click and drag to move] ](/sites/wh/files/inline-images/18150008_N659_jpg%20copy.jpg)

They also wanted to understand the entire supply, from fabrication, to mill order, all the way to erecting on-site. The steel structure for the construction was roughly a $30 million steel package with 6500 tons of steel and roughly 5000 pieces of steel, so it was critical to get it right. It also had to streamline the difficult task of status visualizations of building information and 4D models.

The team also found that bridging the connections with the multiple product sets in use and the corresponding integrations work that was needed was challenging. Furthermore, once established, the ongoing maintenance of those connections, was another challenge.

We also integrated a Tekla-formatted file and it allowed us to overlay the material status information on the 4D Model. Then, with our integration with Microsoft Power BI, we can present in near real-time the status of all the materials so that they can react faster with more transparency on the project.

Construction completed early and under budget during a volatile construction market experiencing supply chain and labor issues.

Q: One of the issues facing a lot of construction firms is with legacy technology. How will DCW be able to integrate with the legacy technology being used by contractors? And what level of data will clients be able to recover from these legacy technologies for the project model?

Jason: I always like to say that the construction industry’s been going digital for about 30 years. I’ve been in the industry for about 35 years, and I was largely responsible for taking people off of field books and into digital data collection. So, going digital is a never-ending process. It’s something that you have to be constantly striving for to see those efficiency gains.

What we try to do with legacy systems is to integrate with the flat files, with the data formats that are open and available out there. One thing we try to do is we actually normalise the data and tuck it into our data warehouse so that it can be accessed and aggregated with other systems that are coming onto the market all the time.

A lot of the industry is moving towards API interfaces that are open and can be connected to, but then with the legacy systems, you still don’t want to lose that information. You want to bring that information forward, so we also integrate with a lot of formats there, too.

Q: What would you say are the biggest barriers to further integration of data using this technology?

Jason: Ultimately, I think we should call the barriers just opportunities. There’s an opportunity for most of the platforms and solutions that are out there to create a more open environment. The maturity of the APIs, the ability to deliver more information and to exchange more information in real time is a huge opportunity for organisations.

In my opinion, it is what is needed in the industry to make construction take that step function forward and go more digital. I think API maturity is going to be a big, constant topic, as is, certainly, moving those legacy systems you mentioned earlier into a more modern approach, a more cloud-connected solution.

Q: How will DCW facilitate progress towards a more sustainable future for construction?

Jason: This is actually something we’re tackling for clients in the Netherlands. Currently, they have instituted a regulation that addresses CO2 emissions, and they require the bidders to estimate what their carbon footprint will be on the project. If they don’t perform against this estimation and they don’t achieve it, then they will actually receive a penalty. That’s a big motivator for people to become more sustainable.

Q: How straightforward is it to set up a new project? Can the DCW Integrations Platform import external data needs? And how does it reduce workloads and save time? Is there an easy security process?

Jason: The platform is really straightforward. It’s really intended to be easy to use and easy to access. We can integrate with various login credentials, for example with OIDC, or we can integrate a company’s active directory, So from the security perspective, it’s quite flexible. What we do is, log in to the DCW platform, set up the projects and then set up the integrations for the clients. We do a lot of that hands-on work. Once it’s configured and tailored to your organization, it’s very easy to add a project. Workflows can then be copied from project to project. It only takes minutes to add a project.

Q: Does the DCW Platform create a consistent structure across the company? Is it an easy-to-use access platform where data from all departments will allow everyone on the project team and in the wider company to work with the same data?

Jason: The platform is essentially a data pipeline network and a data warehouse. So, what we try to encourage people to do is keep using the tools they are currently using. Then, we integrate those tools so that the data is accessible and connected to the platform so that it can be aggregated in a single dashboard and presented in new and more innovative ways for generating project insights, including project status and potential issues. Project to project comparison allows for gradually improving your company’s project performance and sending out better bids.

If you think about the current tool that you are using today – maybe it delivers volume estimations or something like that – but then if you can tackle that or tie that together with, say, the schedule on what you estimated, and then see what happens in the field with regard to the performance of the machines that are doing the work, then you can actually get insights out of the data and across the department from the grading manager to the estimator.

So … it connects those sources and that information.

Q: Does the DCW Platform enhance and encourage collaboration? Is information generated shared in real time with the project team? Is the team instantly updated on changes in the project and schedules, etc.? And does DCW help reduce errors or conflicts?

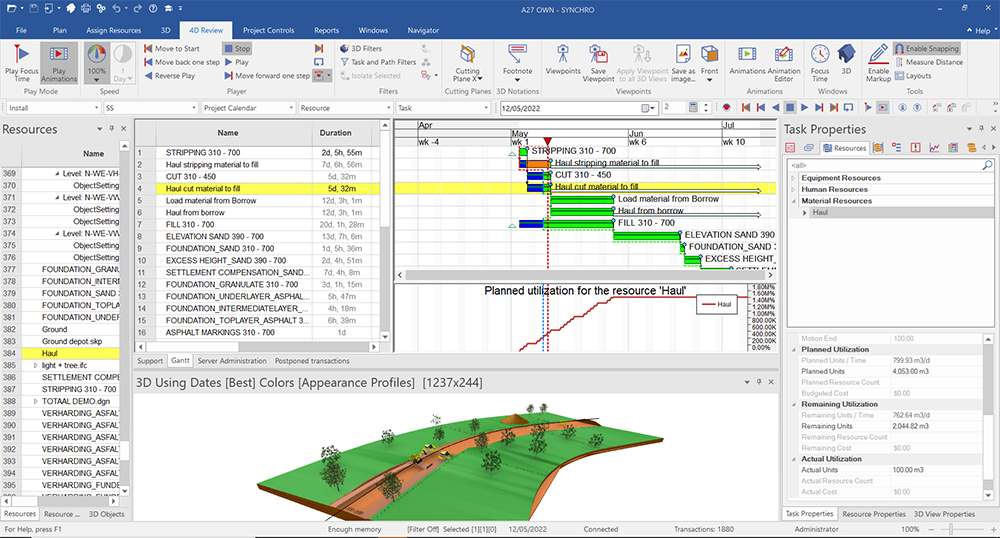

Jason: The platform is all about collaboration. That’s really what it’s geared towards. If you can connect the schedule or the plan, which ultimately results in tasks, you can move that data out to the field and have it delivered automatically for construction execution. Once you’ve connected the people in the field, you can actually return the results in near real-time.

I just say “near real-time” because you don’t want to have data points coming in constantly; it’s just going to be a whole bunch of noise. But if you get the data coming in that you really want to deliver, or that you are contractually required to deliver, then you deliver in near real-time, and you get results, say, in a matter of hours, versus weeks.

We had some clients tell us that sometimes the data they receive is weeks old so they can’t even address the relevant issue which they would have been able to if they had the information a lot sooner.

Q: How will the DCW Integrations Platform be supported and made scalable for the future? Will there be consistent maintenance and support of DCW? Is there a roadmap for future development and how well is it designed to adapt to future technologies?

Jason: Yes, there is a roadmap. At this point, we have a pretty large backlog of things that we want to integrate with and that we’re working on for clients. We try to do our integrations based on real-world client engagements. Then, we make it sustainable and scalable. We package every integration up, almost like a product.

Most of my life has been spent around product management so I look at every integration as a little trainee product. And then I look at every workflow that we tie to the integration as another type of product. Then, when we move from, say, one project to the next, or from one client to the next, the integrations can be reused and reconfigured, if you will, to suit their unique needs.

Every construction business is unique. Even though they might use the same tools, they might use them in different ways. So, what we try to do is make the integrations stable and normalised, and then we try to tailer the deliverables, or the KPIs – the results of connecting the data – so that they suit the client that we are actually working for.

Q: What can you tell us about some of the new developments with DCW? We understand there are some new launches in the pipeline.

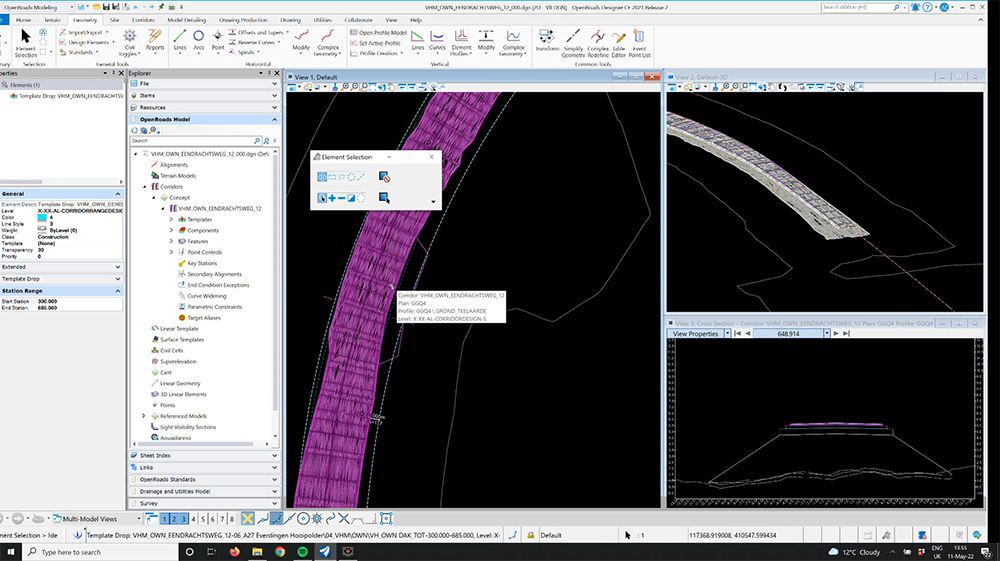

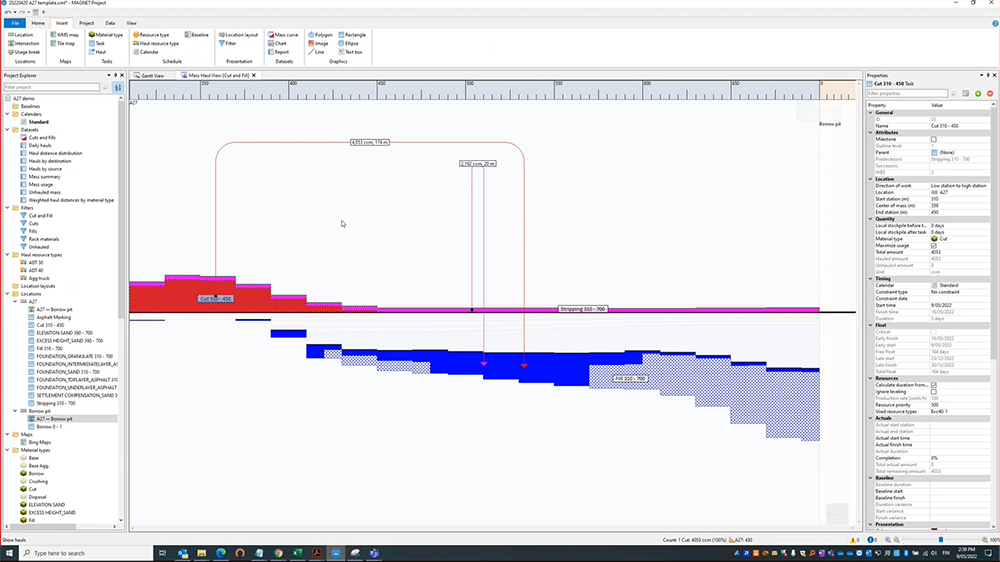

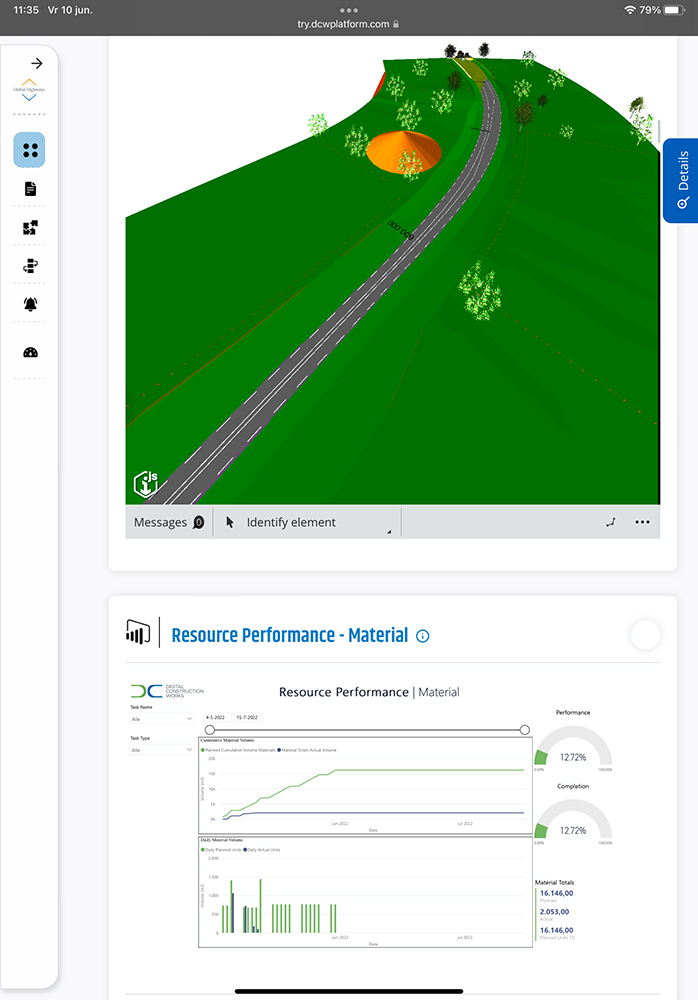

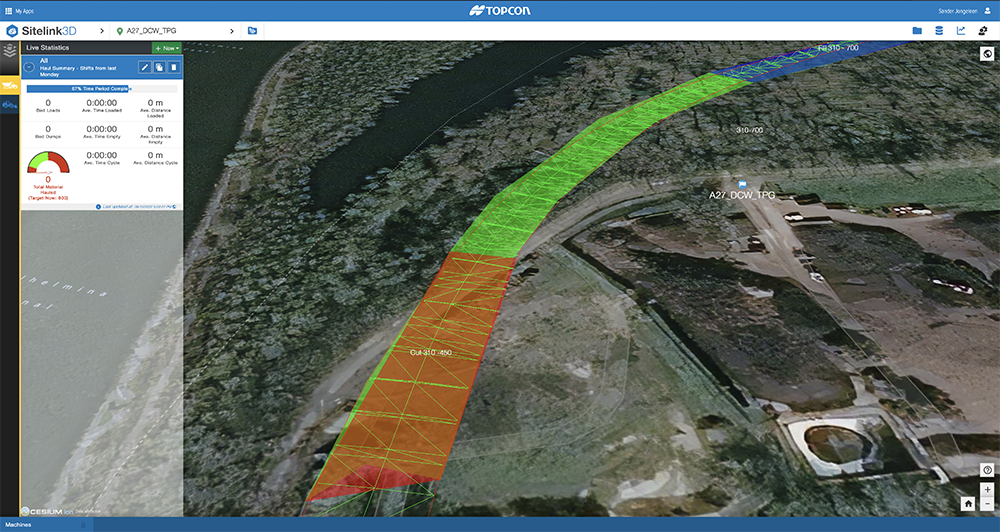

Jason: There’s lots of stuff in the pipeline, for sure. It’s amazing the demand we get from the industry right now. There’s a lot of new technologies cropping up all the time. One of the new technologies that came from one of our shareholders, Bentley, is the integration of SYNCHRO 4D, which is a planning tool, with Topcon’s Sitelink3D product. Topcon is also one of our shareholders.

It’s interesting if you think about integrating, say, the schedule and the tasks with the machines as I described earlier. If you could do that automatically, you don’t have to do double entry. You’re not wasting a whole bunch of time. You can communicate even with subcontractors doing that work in a more efficient and automated way. So that’s one thing we’re really focused on.

And, of course, we’re focused on round-tripping the data back from that system, as well. We want to do it in a way that, for example, allows the subcontractor working for the GC to review and then approve the information he wants to push back. And to do it digitally.

Q: Is there anything else in the pipeline?

Jason: Yes. Something else that we’ve taken on recently is we are working with Topcon’s monitoring business and with the Bentley sensemetrics business. We’re working on integrating those solutions so that we can start tying IOT sensors and monitoring systems to the construction ecosystem just to be able to deliver more information related to the project in near real-time, as I described before.

Q: You have two primary shareholders in DCW. How easy is it for you to integrate technology from competing companies into the DCW work file?

Jason: That’s a really good question. One of the things that our shareholders decided when they started DCW was that DCW needed to go out and be an agnostic integrator in the industry. The only way we can move the industry forward is through that kind of thought leadership and around the idea that market expansion is good for everyone.

So, if we can get the market to expand and adopt more technologies, it’ll benefit everyone, including the shareholders. Honestly … we’ll integrate with anything that can be integrated.

Q: What effect do you think the pandemic has had towards driving the construction sector towards digitalization?

Jason: From what we experienced in the beginning, it was interesting because I think everything just came to a grinding halt which was pretty eye-opening, I think, for the world. Then, all of a sudden, everybody started to realise that they could do a lot more by being remotely connected if they had the right tools to engage in those tasks or those meetings, or whatever they are.

You saw a lot of new technology come on very quickly in that time. And I really do believe that there is a lot more done today digitally than even, say two years ago, as a result of the pandemic. I think people being remote is just something we’ve all accepted now. And I think it’s going to continue.

I also think that DCW is in a good spot because that’s exactly what we’re focused on – being able to do more digitally and remotely. You should be able to work with systems that are out in the field and get the information back to office without having to drive out to the site or meet face to face. It’s absolutely a trend we’ve seen … and one we believe will continue.

Watch DCW's Integrated Highways Video here: https://www.digitalconstructionworks.com/solutions/the-dcw-integrations-platform/#connecting-site-to-office-video

See the full Roundtable Video below: