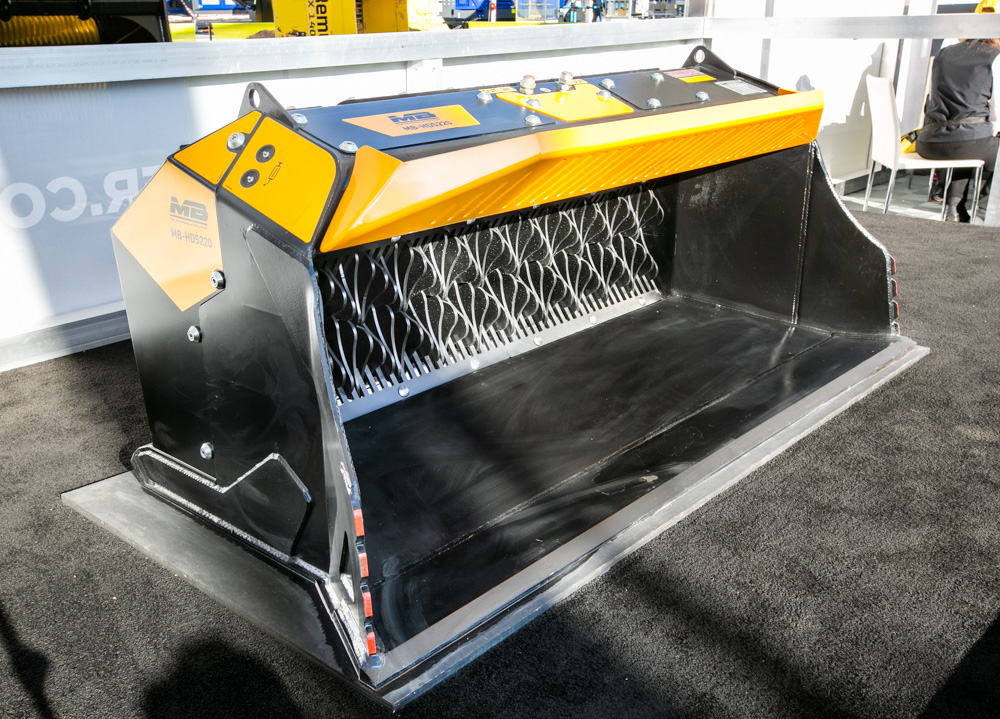

MB Crusher says its load capacity of 0.61m3, which the Italy-based manufacturer says makes the bucket “compact, versatile, and highly manoeuvrable.” The new MB-HDS220 padding bucket should also make work easier, reduce processing time, and save on operating costs, the company says.

The size of the mouth opening is 2.2m, a width which will allow easy loading by ensuring that the tracks or wheels of the carrier machine remain clean, says MB Crusher.

The inlet is designed to convey material quickly to the rotors. MB Crusher says that maintenance is simple with greasing being centralised and done on-site … as with all its products.

The coupling system is designed to allow a maximum margin of movement of the operating machine. This system allows excellent visibility of the material to be worked on and of the site.

As with the other HDS models, the MB-HDS-220 allows the operator to change the rotors quickly and directly on-site. This makes it a versatile machine with which different types of material can be processed efficiently and quickly.

The MB-HDS-220 is designed to facilitate work on all construction sites where there is a need to aerate packed topsoil. This facility could be useful, for example, when there is a need to reclaim and clean soil from various demolition debris, stones or roots, to select material for covering pipes or trenches, or for making the bedding.