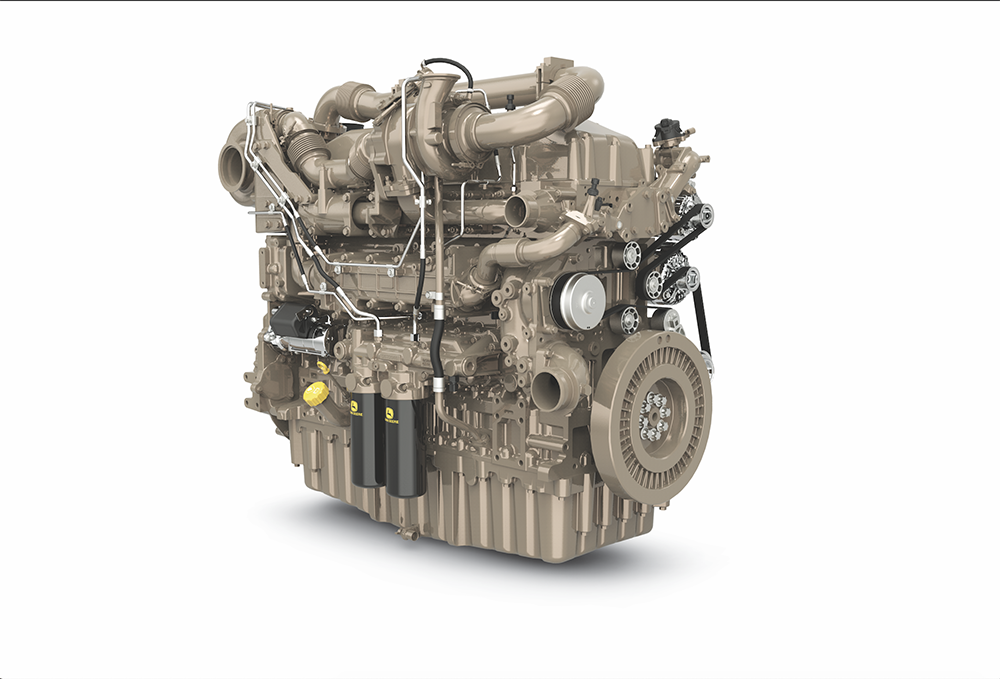

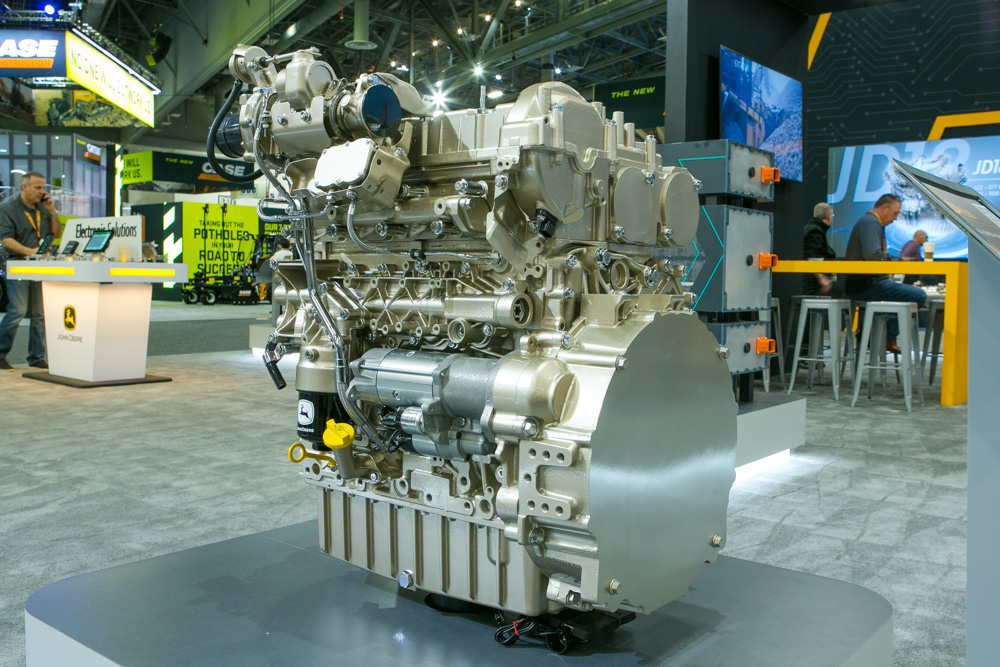

The Deere Next Generation engine line-up includes the JD4, JD14 and JD18. The engines were built from “a clean sheet of paper,” which essentially meant stripping the engine down to its block and designing from there, said David Wendt, account manager at John Deere.

This allowed Deere to provide maximum power at the smallest size and enable the use of diesel or alternative fuels. It also meant relocating (and protecting) the wire harness, an enormous benefit for technicians.

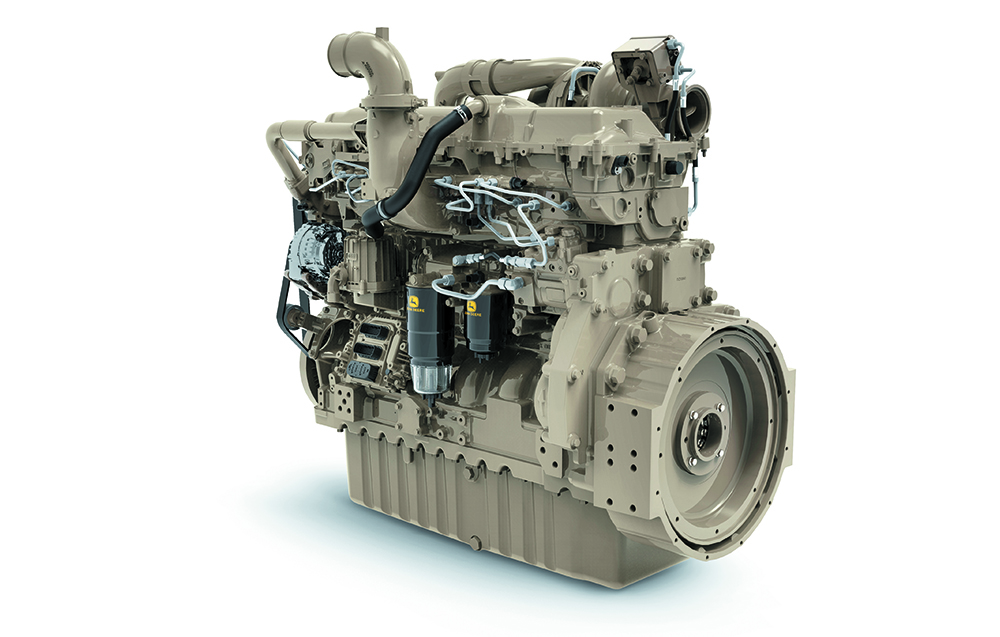

The 3.9-litre JD4 provides up to 120kW of power and fills a void beneath the current 4.5litre model.

“For some OEMs, the 4.5 litres is too large,” said Wendt. “The JD4 is smaller in size, with less weight and smaller dimensions.

All the Next Generation engines can integrate alternative fuels, yet have no unnecessary technology, Wendt said. “We’re not using technology where we don’t have to. We’re using technology in the smartest way possible.”

The JD4 will power OEM products such as water pumps, telehandlers and woodchippers.

While released in North America, the engine will also be a good fit in Europe, said Florent Goujon, account manager for Deere.

Its use of renewable fuels is necessary in the region, and European businesses tend to prefer smaller machines, he said.

“When thinking about how to move toward a low-carbon future, we as an industry need to be open to a variety of solutions to meet the vast and varied needs of the off-highway market. There will be no singular solution to reaching our goal of low- and near-zero-carbon emissions,” said Pierre Guyot, senior vice- president of John Deere Power Systems.

“We must prioritise the continued improvement and innovation of ICE technologies, as renewable fuels and electric and hybrid drivetrains play a role in creating a more sustainable future for the off-highway industry.”

Booth W40844