No two conveying systems are alike, even if the primary task of transporting bulk material from A to B appears comparable. The components and the system must be adapted to the material being conveyed. The mass flow to be conveyed and height differences that need to be overcome over the length of the conveyor line are important factors that must be addressed when designing a system.

The right layout is all-important and the BEUMER Overland Layouting Tool is central for ascertaining the ideal layout for the system at an early stage of the project and designing the ideal conveying solution together with the customer.

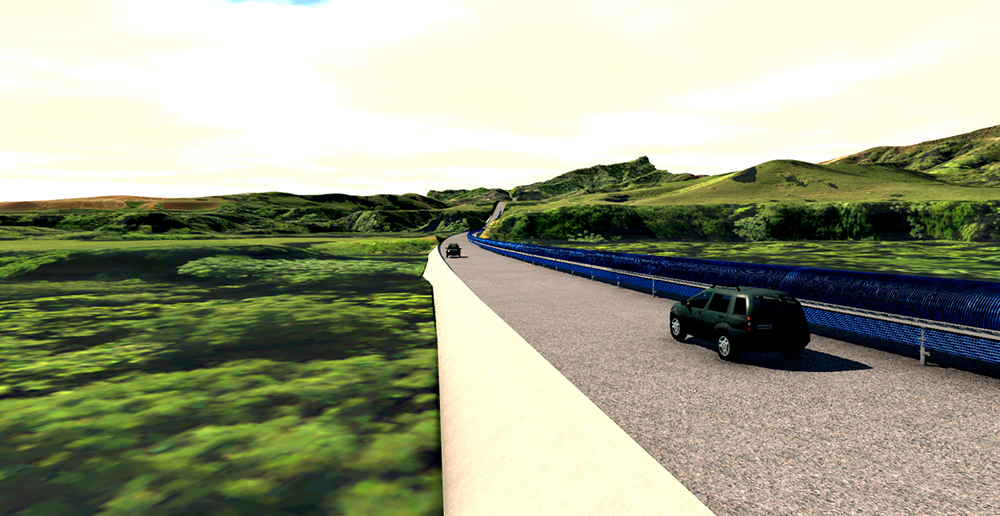

It generates a digital 3D model of the conveyor in the virtual landscape during project planning, more or less automatically, according to the company. The critical topography data can either be provided by customers or drones that capture terrain data. These 3D visualisations are also ideal for supporting mining companies in their public relations work.

Important factors such as cut-and-fill volumes - the necessary excavation work - and the required steel structures for the conveyor can be evaluated and illustrated on this basis. This procedure considerably accelerates the project planning process and enables BEUMER to provide project-critical data to the customer at an early stage of the project.

Topography has a significant influence on the design of the conveying system. An in-depth analysis of various dynamic load cases and a thorough investigation of the technically feasible horizontal and vertical curve radii must be conducted to design the system in the most efficient and environmentally friendly way. This is especially true for longer and more difficult conveyor lines. Potential obstacles that must be considered during the planning phase include residential areas, roads and rivers.

Today, BEUMER can design curved overland conveyors of up to 20km or longer without the need for a transfer tower. The conveying capacities of a system like this are more than 20,000 tonnes per hour.