Joe Incontri* reviews the advantages of new radar technology that offers accurate and continuous level measurement in cement plants

A variety of issues affect accurate continuous level measurement inside cement plants. The most critical concerns are dust, heavy build-ups, low-reflective media and uneven surfaces in conical and/or air-injected silos with internal objects.

Now, new frequency-modulated continuous-wave – FMCW - radar technology, combined with high signal dynamics, offers a way to accurately and reliably measure product levels.

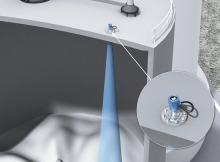

One example of this new technology is Krohne’s Optiwave 6300 C non-contact radar level. Within its measuring range of 80m, the device provides a ±3mm standard accuracy.

Moreover, due to its small antenna beam angle, tank internals or low reflective media are no longer an issue. To control the production and secure the supply of cement, the level sensor’s measuring signal is transmitted to the control room. There the silo’s level can be continuously monitored.

The technology improves the supply inventory of remote cement silos and minimises inefficient loading and costly delays for the end-user.

Installation and operating costs are significantly lower with non-contact radar level technology. The two-wire radar needs less wiring, significantly reducing installation and operating costs.

The level sensor is equipped with Pactware software; an installation wizard simplifies configuration. Device software uses dedicated algorithms to adapt each instrument to its specific application, making it particularly suitable for measuring uneven product surfaces.

X-Head: Antenna aiming no longer

In addition, the drop antenna’s shape and smooth surface made of polypropylene or polytetrafluoroethylene (PTFE/Teflon), minimises build-up. As a result, the 80mm or 150mm antennas need less cleaning and do not require expensive purging systems.

This new level measurement technology is used in several cement industry applications, including level measurement in cement silos, cement dust level measurement and fly ash measurement.

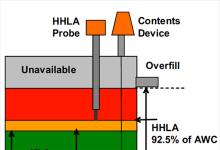

A cement silo’s level must be continuously measured to control production and ensure the supply of cement to downstream products. At one cement producer, where cement is stored in a large silo with a holding capacity of several thousand tonnes, operators found that the level did not decrease evenly as cement was removed from the bottom of the silo.

Instead, deep pits formed and large chunks adhered to the silo walls.

Moreover, the combination of a dusty atmosphere and low reflectivity (the dielectric constant was 1.8-1.9 Σr) presented issues for the ultrasonic level measurement being used.

The ultrasonic device was then replaced with the new contactless level measurement device.

The

Installation was further helped by the device’s pre-configuration which required uploading only a few more parameters into the device, including silo height, block distance and cone shape.

In addition, the new device required less maintenance because it lacked moving parts. The antenna’s ellipsoidal and completely-enclosed shape, along with its smooth surface, minimised the need for dust protection, regular flushing and other periodic cleaning.

The technology was used also at a Chinese cement plant incorporating ball mills to grind clinker. This process generates large volumes of cement dust which is collected, stored and then fed back into the production cycle.

The 9m tall dust storage silos are equipped with air injectors, which fluidise the dust and prevent it from forming up on the silo walls. This simplifies extraction, but the injectors lower the dust’s dielectric constant to 1.4 Σr. Combined with the dust laden air, the lowered dielectric makes it more difficult to obtain a reliable and accurate level measurement.

Plant operators had previously tested ultrasonic, time-domain reflectometer and pulse radar devices. But none of these technologies could meet the cement plant’s measurement requirements. To provide the required accuracy and reliability in level measurement, Krohne installed an Optiwave 6300 C level meter with a 150mm polypropylene drop antenna and a flange connection of around 150mm.

Fitted to the silo roof, the two wire FMCW non-contact radar continuously measures the dust volume left in the silo. Several months of testing showed the device worked well and the company equipped nine additional silos with similar measuring devices.

X-head: Fly ash level

One US building materials producer previously used an ultrasonic level meter to monitor the amount of fine fly ash powder in a conical silo 6m by 20m high.

However, the company found it difficult to conduct accurate measurements due to the low reflective medium in a dusty environment. The challenging product surface has a low dielectric constant (3.3 Σr).

There was also a tendency for the fly ash to build up on the silo walls and the level radar's antenna. This led to regular instrument failure, with subsequent process interruption. On several occasions, trucks were kept waiting sometimes for hours.

The producer sought out a reliable level meter that has an approval for use in hazardous dust areas. They opted for the Optiwave 6300 C level sensor, installing the device with a 150mm polypropylene drop antenna, using a 150mm flange.

The 24-26GHz FMCW level meter generates a wave signal that enables the producer to accurately and reliably measure the product level in the dusty fly ash silo. The measuring signal is transmitted via a 4-20mA signal to a control room where operators constantly monitor the silo level.

With the new level measurement technology, inefficient loading and costly delays due to false level indication are no longer an issue. In addition, workers no longer need climb to the top of the silo to clean the sensor, thus substantially improving worker safety.

Joe Incontri is director of marketing and projects at Krohne, a manufacturer of industrial process measuring technology with a head office in Duisburg, Germany and production facilities in 12 countries.