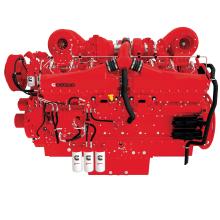

Cummins has opened a new European Master Rebuild Centre for high power engines in Krakow, Poland. This is first of its kind in Europe and the firm has spent US$10 million to develop of the Centre, which remanufactures Cummins high power engines with displacements of 19-78litres, and in the 335-2,610kW power range. This includes the QSK19, QSK38 and QSK60 engines.

The new 4,600m2 facility has been developed to meet growing demand across several sectors for high power engines that have been rebuilt and. This move will boost the firm’s customer service in Europe.

Rebuilt engines are becoming the first option for customers who want reduced costs and greater engine uptime. The firm says that its engine rebuilds go through a six-stage remanufacturing process. The engines are disassembled, cleaned, inspected, re-machined, reassembled with Genuine Cummins parts and tested.

A rebuilt engine has a shorter lead time than a factory ordered unit but performs to the same specification. A typical cycle time is just 35 working days. A remanufactured engine provides up-front savings for customers when compared with a new, first-fit engine, increasing revenue and efficiency.

Cummins will offer a range of rebuild and remanufacture options at the Centre. Its Ultimate Remanufacture solution sees the full dismantling and reassembling of the engine, with the replacement of all worn components with Cummins Genuine parts, including wear and tear components. Ultimate Remanufacture engines have a full factory warranty equivalent to a new engine.

The Centre in Krakow is close to an international airport and major highway, centrally located within the firm’s European network. It also benefits from the highly skilled team that were based at the firm’s existing Krakow site.

It is the newest of 13 Cummins Master Rebuild Centres around the world, all providing rebuilds in factory environments.

Ann-Kristin de Verdier, executive managing director for Cummins’ Europe Distribution Business, said: “We’re thrilled that this state-of-the-art facility has officially opened. It is the result of a significant and strategic investment to deliver more choice to our customers across Europe, ultimately helping them to reduce costs and boost productivity.”

The new European Master Rebuild Centre is an integral feature of a new base in Krakow, which is home to a warehouse, workshop and administrative offices. The new Centre is expected to be key in Cummins’ wider growth strategy in Poland and across Europe.

Cummins’ also developed the new facility to support its Destination Zero and Planet 2050 commitments to environmental sustainability. It features solar panels, charging points, a high-tech microbiological wash bay which reuses 100% of water used on site and other state-of-the-art solutions. The engine remanufacturing process also requires 85% less energy than manufacturing new engines, and reduces the use of raw materials, packaging and the production of scrap metal.