When the UK roads authority National Highways – formerly Highways England – announced its new Digital Roads strategy at the beginning of September this year, one of the headline elements of its vision was the creation of a digital twin of the network. The twin would help predict when early interventions were needed to prolong the life of roads and keep traffic flowing.

“Combining ‘live’ data from intelligent materials in the existing road surface with a digital twinning system that visualises the road and its condition will identify when maintenance work is needed, with roads able to repair themselves using self-healing materials,” claimed the National Highways press release. “This will dramatically reduce the need for time-consuming and costly onsite inspections, prevent unnecessary delays to drivers and reduce the emissions generated by roadworks.”

Digital twins are not simply a virtual version of a physical asset but must be linked to each other by flows of information, whether that is volume of traffic, type of vehicles or structural monitoring. To gather that information, our highway networks will require multiple sensors, some of them embedded in the road.

At the 7th Eurasphalt & Eurobitume (E&E) Congress, held virtually in June 2021, delegates heard how embedded sensor technology is under development, by both commercial and academic organisations. R&D work is also underway outside Europe, in countries including the US, China and Japan.

Two decades of smart roads

Currently, methods for road pavement inspection and testing can be time-consuming and costly. Surface condition can be inspected visually or automatically, using scanners. Structural integrity can be assessed through technology such as falling weight deflectometers (FWD) or possibly ground-penetrating radar (GPR). Often destructive testing, such as the taking of cores, is necessary.

Embedding sensors into the road would mean that, having installed them within the asphalt, information about the state of the road would always be available without having to carry out any more interventions. Sensors measuring parameters such as strain, movement and temperature would be embedded in the road and used to predict when maintenance interventions were needed.

This is not a new idea. The Virginia Smart Road project was conducted in the late 1990s and involved embedding a variety of sensors at different depths over a 3.3km-long stretch of road.

More recently, contractor Eiffage, with the University of Lyon and ENTPE, the National School of State Public Works instrumented part of the A41N highway near Lyon in 2012 with strain gauges, temperature probes and Fibre Bragg Gratings (FBGs).

Also in France, researchers embedded sensors in the slow lane on part of the A10, which runs between Paris and Bordeaux. The programme uses a wireless data acquisition device called PEGASE, which was developed by the French Institute of Science and Technology for Transport, Developments and Networks, IFSTTAR, and is available commercially through French company I3IP.

Clearly there have been significant advances in technology related to data acquisition and transfer since those early instrumented sections laid 20 years ago. Wireless sensors are now commonplace in many applications and processing power, together with artificial intelligence (AI), offers better opportunities to make use of the data collected.

However, challenges still remain. Wireless sensors require batteries which have a finite life, and there are still questions about robustness and how sensors can be best protected and preserved, usually during the installation phases.

Impact of overload

At the E&E Congress, researcher Patricia Kara De Maeijer from the University of Antwerp, spoke about the University’s ongoing programme looking into using FBG to investigate the impact of heavy goods vehicles (HGVs) on pavements. HGVs are often loaded above legal limits, increasing damage to the pavement and reducing its service life.

A FBG consists of a distributed reflective element inside an optical fibre that reflects a limited wavelength range and transmits others. When the mirrored section of fibre moves, due to strain in the pavement, the wavelengths emitted by the fibre change. One of the biggest challenges in using such technology in asphalt pavements is how to install them without damaging them during the asphalt laying.

De Maeijer and her fellow researchers first installed FBG sensors, which are commercially available, in 2017 in a cycle path at the University. They used two different installation methods. First, the fibres were put into prefabricated asphalt units, the others installed in grooves in the bottom of the asphalt layer.

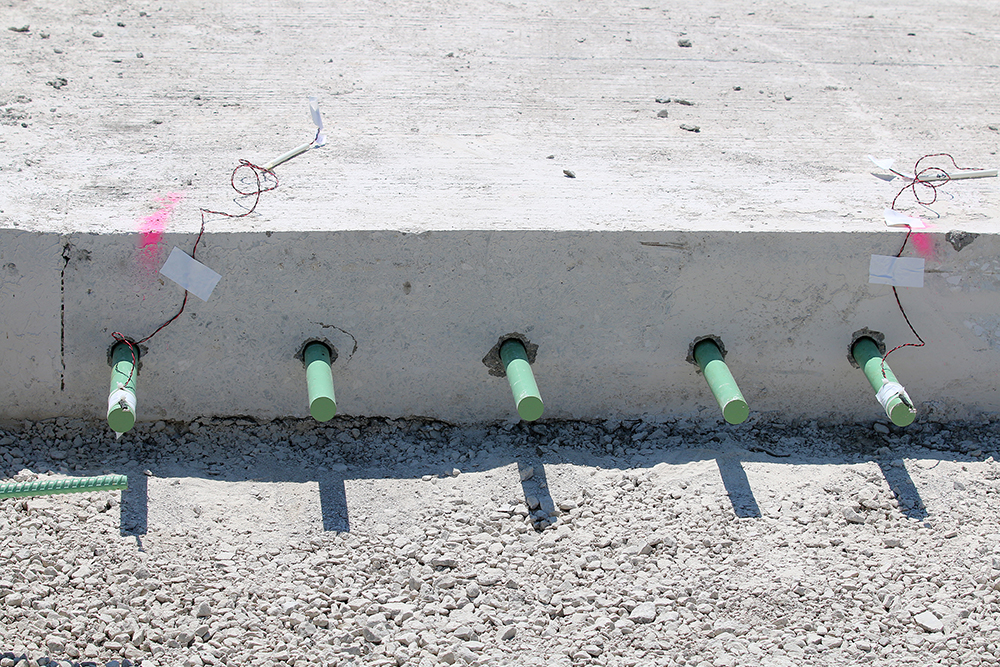

The second installation came in 2019 at the Port of Antwerp in a heavy-duty pavement, with the FBGs installed longitudinally and transversely in each of three layers of asphalt pavement. The researchers used three different methods of placing the sensors: in prefabricated elements, in grooves and in a geogrid.

“During the actual construction of the heavy-duty pavements, the system suffered significant sensor losses which mostly was related to the loss of sensors in the geogrid and also in the prefab element,” De Maeijer told the E&E Congress.

Following on from that project, the researchers installed FBG strain and temperature sensors in another section of road at the Port of Antwerp, installing the sensors in grooves in areas of mortar laid on top of the unbound road base. Two types of mortar, epoxy and cement, were trialled with the survival rate achieved for the sensors of 100%.

Using data mining and processing, the information gathered from FBG strain and temperature sensors could be used for several different things, according to De Maeijer. These include automatic vehicle detection, detecting high strain values or strain values/axle, numbers of vehicles and temperature fluctuations between the day and night.

infraTest’s new sensors

One of the latest additions to the range of highways testing equipment offered by specialist infraTest is sensors. “Our newest innovation is infraTest sensor technology,” the company’s managing director Matthias Martus told the E&E Congress. “We started two or three years ago with the design of temperature sensors which we put into the asphalt during the paving process. We put them into the different layers – surface, binder and base layers.”

The sensors can be set up so that they measure temperature at predefined time intervals, with the possibility of varying those intervals. The sensors are wireless which means that they can be programmed and configured after installation, said Martus.

The sensors store data which is then exported wirelessly using RFID (radio-frequency identification), either manually or automatically. Currently, said Martus, the battery life of the sensors is between two and three years, depending how often the sensors are set to take readings.

infraTest also supplies acceleration sensors which detect vibrations in the form of acceleration when a vehicle passes over them. These sensors are wired, transmitting data via a cable to a control unit which can then send the data to the cloud.

“We can measure axle load, axle configuration, traffic density, vehicle type and, with long-term studies, we can have information about the life cycle and make life cycle forecasts,” said Martus.

Self-powering sensors

In Indiana, researchers from Purdue University, led by professor of civil engineering Luna Lu, have developed sensors that can be embedded in concrete roads to monitor strength through changes in properties such as hydration, stiffness and compressive strength. The sensors are piezoelectric sensors which can generate an electric charge in response to mechanical stress – so they require no voltage or current source.

The sensors have been installed in Interstates 465 and 74 for the Indiana Department of Transportation for nearly two years. Purdue also reports that it is working the Federal Highway Administration (FHWA) to install them in Texas, Colorado, Tennessee and Missouri.

The sensors can be used initially to check that the concrete has reached sufficient strength to bear vehicles. Over longer periods of time, they can alert road owners when the concrete road is starting to fail so that repairs or replacement can be planned much further in advance.

“Our sensors could help make data-driven decisions to determine the construction schedule and improve the quality of concrete construction,” said Lu. “Being able to track concrete strength over a longer period of time would help engineers understand if they’ve over- or under-designed roads and better determine when to replace the concrete.”

Effective analysis of all the data collected should also help road owners and designers to understand the actual loading that road pavements are enduring – and to design future pavements accordingly. And with systems such as that being trialled by the University of Antwerp, embedded sensors will also offer road owners the chance to police their road users; overloaded HGVs could become a thing of the past.

Digital Strategy

National Highways’ Digital Roads strategy sets out the road authority’s vision for digitalisation, grouping them into three areas: design and construction, operations and customers. Intelligent asset management is one of the themes of the digital operations vision – as well as better data collection and processing, National Highways sees connected and autonomous plant being deployed to carry out more coordinated roadworks.