Digitalisation is changing the construction industry, with new technologies and applications aiming to meet demand for greater sophistication.

The quality requirements in road construction are increasing in many countries. Projects have been put to tender that feature additional documentation requirements, intended to boost road construction quality. In Germany for instance, these projects are known as Quality Road Construction 4.0 (QSBW 4.0).

The additional requirements include documenting asphalt temperature values and pass counting for compactors, and these more stringent requirements present construction companies with challenges.

German firm

The latest version is called BPO Lite and compared to the existing BPO Asphalt, the new package dispenses with extensive work preparation and allows immediate connection, process control and documentation of the construction site without lengthy planning.

The premium version of BPO Lite can be integrated into the resource planning so that no additional effort is required. After construction has been completed, all analysis reports can be generated, downtimes evaluated and lap times checked, as well as the paving locations for delivery notes.

The package is said to allow medium-sized and smaller construction companies to meet the QSBW 4.0 regulations, as well as increasing requirements from clients.

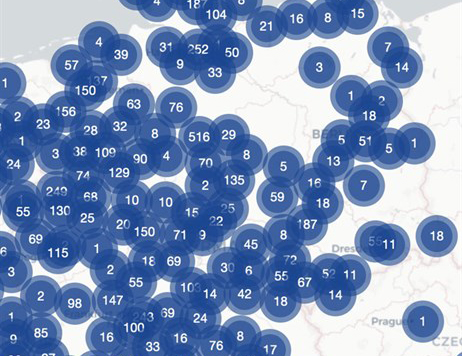

BPO Lite connects mixing plants, truck logistics, construction sites and site managers. Delivery note data can be transferred automatically to BPO Lite at more than 500 mixing plants in Europe. During construction, the site manager receives data showing how much material has already been paved, what is being transported to the construction site and what quantities still have to be produced. Truck logistics can be integrated via the tracking app, while drivers can record pauses, send messages and view transport orders with specified times as well as planned routes.

At the construction site, trucks can be unloaded and data recorded using a smartphone. Delivery notes can also be recorded offline using the integrated QR code scanner. The delivery note can be signed on a smartphone or tablet, sending electronic delivery notes to mixing plants for invoicing. BPO Lite can be used on the construction site, whether in a paver's external control panel, in the construction office or on the site manager's smartphone.

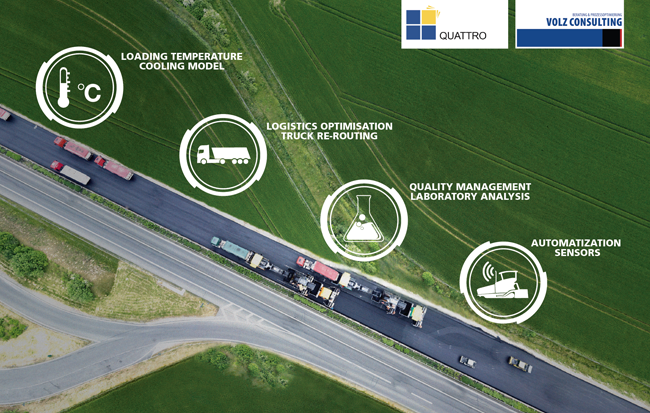

The BPO QUATTRO system is now well proven. In 2015, Volz Consulting carried out the first QUATTRO project on the A7 near Kitzingen, where thermal profiles of hot asphalt surfaces were recorded and data on deliveries to the site were logged. Target and actual paving parameters were added to the analysis and formed a complete data model of a road project according to Building Information Modelling (BIM) practices.

Since then, QUATTRO has been expanded and has added the new requirements to the three main BPO Asphalt modules for planning, real-time networking and analysis.

At the mixing plant, loading temperature is recorded manually or transferred automatically. Minimum and maximum values limit permitted loading temperatures and provide feedback on measured values. After loading, temperature values are displayed in real time on the site manager’s tablet. Cooling models forecast expected unloading temperatures of deliveries. Material that is too hot or too cold is highlighted by colour-coding. The site manager can monitor deliveries and can check and document temperature values.

During transport the trucks are tracked via GPS and the QUATTRO module calculates the estimated time of arrival at the site. The estimated time of arrival takes congestion into account and can suggest a better route for the driver. The site manager is informed in real time if a truck is delayed and when it will arrive.

At the construction site, measured values are recorded during paving. For each station, the layer thickness and cavity content are recorded by app and the degree of compaction is calculated. This data is displayed so that the site manager can check paving parameters, with information available as a report at the end of the job.

In addition, numerous sensors can be integrated into BPO. These include pass counting for rollers and heat monitoring systems, as well as sensors for recording the paving speed, the paving width and the layer thickness.