Bentley Systems has unveiled a wealth of new construction software technologies that can help optimise the progression of road projects - Mike Woof writes

A host of new tools and software developments from Bentley Systems will help designers and construction firms deliver projects more quickly and efficiently. Senior vice president for Bentley Systems is Bhupinder Singh and he explained, “Our users are using more software and more devices than ever before and they’re creating more data.”

He said that

Senior vice president at Bentley Systems, Bhupinder Singh, explained that mobile devices offer major benefits for construction users

Bentley Systems has unveiled a wealth of new construction software technologies that can help optimise the progression of road projects - Mike Woof writes

A host of new tools and software developments from4019 Bentley Systems will help designers and construction firms deliver projects more quickly and efficiently. Senior vice president for Bentley Systems is Bhupinder Singh and he explained, “Our users are using more software and more devices than ever before and they’re creating more data.”

He said that this is leading to greater complexity for construction projects. For technology specialists such as Bentley, this presents the opportunity in offering ways to reduce such complexity and also provide greater data security by merging information from different sources. “We’re talking about convergence of data and synchronisation. We believe the cloud is an enabler of this convergence.”

Singh continued that the firm’s ProjectWise package is playing a key role in delivering a secure capability for sharing data and said, “We’ve taken ProjectWise and extended the benefit of that throughout the supply chain.”

Digital engineering models offer performance advantages and Singh said, “You’ll have data across multiple formats and across a long period of time. That’s what our platform does.”

Singh explained that the firm’s tools can provide effective content management, "We need to deliver consistency. Spatially enabled data through the internet is another feature of this tool.”

As all the data is lined, Singh said that this allows the users to navigate and edit through the same interface. “Spatially enabled data through the internet is another feature of this tool. All the data is linked. It’s not just 2D; it’s 3D and real engineering precision 3D,” he said.

Construction modelling allows users to construct simulations for road construction and Singh explained that all suppliers will be able to deliver materials as they are needed throughout the progress of a project for example. Connected projects meanwhile provide a single source of information. Singh said, “The open road concept lets our users explore concepts early on. Before, conceptual models have been a dead end. Now they can carry on into design.”

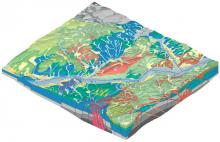

One of the recent acquisitions by Bentley Systems has been of the French firm, Acute 3D. This company has brought useful tools to the Bentley portfolio and the firm says it can take any kind of photos and make 3D models out of them. Photos can be shot with any kind of camera, from an iPhone up to 3D photogrammetry.

These images can be stitched together using a reality mesh and full 3D capture technology to make a 3D model. However Bentley says that this system comes in addition to point cloud technology, rather than as a replacement. Point clouds offer greater accuracy and are better suited to final design rather than the lower accuracy 3D models offered by photos that are appropriate for representations.

A major advance benefiting road construction projects comes from the new building information modelling (BIM) tools incorporated into Bentley’s latest version of the OpenRoads package, its CONNECT Edition. The OpenRoads software allows users to produce intelligent 3D models and share information within project teams.

However the new CONNECT Edition takes this further with modelling tools for roads, bridges, geotechnical information and overall site optimisation. Because the package allows teams greater access to project data, issues such as clashes or design changes can be dealt with more quickly and efficiently, reducing the time needed to resolve problems. The package also allows users to consider a variety of different options for a project, evaluating the respective engineering and cost implications and finding the best solution. Comprehensive analysis of design alternatives allows the project designer, contractor and client to collaborate on decision-making processes as a project evolves.

Finalists in the Bentley awards had all used the OpenRoads package in handling projects, with AECOM’s work to upgrade the E4 route in Sweden being a case in point. The project to widen the route to highway status was complex and involved the participation of 70 personnel across 15 sub-consultants in four different countries. The OpenRoads package was used to define the civil software standards across the design teams and improve communications between the separate participants. With 3D models, the team members were able to detect clashes early in the project cycle and resolve issues, reducing problems from errors in the field.

With the route extending for around 31.5km and including 28 bridges, there were many issues to resolve. Many of the bridges were too narrow to cope with the widened highway and were in need of replacement, while nine of the structures could remain. The designers were required to use as much of the existing carriageway as possible, so as to minimise the quantity of road construction, paving and materials required. There were also 34 areas containing archeological remains and a high voltage cable underground that the project designers had to ensure would remain undisturbed by the construction work. A key factor of the project was to minimise the impact to the environment for the project, which was highly complex. A member of the project team said, “It’s about how you manage the information.”

The project team split the work into assets and put the data into master models. Around 100GB of data from point clouds was downloaded to optimise the work. Overall, the team was able to save up to 100hours on the civils, and from this were able to utilise these new skills in optimising ramps and exit design and look at various options, resulting in further time savings.

The Bentley software has been used on the Herning-Holstebro road project in Denmark for the Danish Road Directorate. This has been used as a full-scale trial for the use of digital tools in road construction and also to help establish the digital standards that will allow BIM to be used for projects in the country. The work is underway at present and the contractor is employing machine control technology, using programming based on the digital models.

This 39km project involves the construction of eight interchanges and four railway crossings as well as five landscape bridges. Worth some US$580 million, the project has required participation with several other organisations, this process aided by the ease of file sharing. Because so many different groups are involved in the project, the decision was taken to share these digital models across the team and this approach has helped reduce design time and find any problems early on.

Bentley’s software has also been used on the A6 project in Manchester, involving widening the main route linking the city with its airport. Much of the design work is being carried out by8289 Grontmij, while other partners in the project are 2435 Carillion, Morgan Sindell and 1397 AECOM. The work is being carried out as a BIM project and the upgrading of the route should be complete in 2017. The designs are being checked before the federated 3D model is created, with the team using ProjectWise and storing all the data in one place.

To improve efficiency the team holds interdisciplinary meetings at regular intervals. Clash reports are relayed back to the team, which was able to resolve 3,800 clashes over the first year. The team uses a novel process with ‘soft’ clashes, allowing 200mm between features as this maximises the use of the whole working area. By eliminating the ‘hard’ clashes, the design team estimates that it saved over £1 million in construction costs, while also delivering a safer project. According to the partners, the use of the 3D models has allowed the designers a greater understanding of the construction work, and the contractor a better understanding of the design.

As Gronmij is a member of the8100 Highways England BIM Working Group, the progress made with this project will also allow BIM to be implemented on other road projects in the UK.

In choosing the winner from these three highly innovative projects, the jury faced a tough decision. However Grontmij’s innovation with the design of the A6 widening work was decided to have the edge over the other projects and it was awarded the winning place in the Innovation in Roads category.

A host of new tools and software developments from

He said that this is leading to greater complexity for construction projects. For technology specialists such as Bentley, this presents the opportunity in offering ways to reduce such complexity and also provide greater data security by merging information from different sources. “We’re talking about convergence of data and synchronisation. We believe the cloud is an enabler of this convergence.”

Singh continued that the firm’s ProjectWise package is playing a key role in delivering a secure capability for sharing data and said, “We’ve taken ProjectWise and extended the benefit of that throughout the supply chain.”

Digital engineering models offer performance advantages and Singh said, “You’ll have data across multiple formats and across a long period of time. That’s what our platform does.”

Singh explained that the firm’s tools can provide effective content management, "We need to deliver consistency. Spatially enabled data through the internet is another feature of this tool.”

As all the data is lined, Singh said that this allows the users to navigate and edit through the same interface. “Spatially enabled data through the internet is another feature of this tool. All the data is linked. It’s not just 2D; it’s 3D and real engineering precision 3D,” he said.

Construction modelling allows users to construct simulations for road construction and Singh explained that all suppliers will be able to deliver materials as they are needed throughout the progress of a project for example. Connected projects meanwhile provide a single source of information. Singh said, “The open road concept lets our users explore concepts early on. Before, conceptual models have been a dead end. Now they can carry on into design.”

One of the recent acquisitions by Bentley Systems has been of the French firm, Acute 3D. This company has brought useful tools to the Bentley portfolio and the firm says it can take any kind of photos and make 3D models out of them. Photos can be shot with any kind of camera, from an iPhone up to 3D photogrammetry.

These images can be stitched together using a reality mesh and full 3D capture technology to make a 3D model. However Bentley says that this system comes in addition to point cloud technology, rather than as a replacement. Point clouds offer greater accuracy and are better suited to final design rather than the lower accuracy 3D models offered by photos that are appropriate for representations.

A major advance benefiting road construction projects comes from the new building information modelling (BIM) tools incorporated into Bentley’s latest version of the OpenRoads package, its CONNECT Edition. The OpenRoads software allows users to produce intelligent 3D models and share information within project teams.

However the new CONNECT Edition takes this further with modelling tools for roads, bridges, geotechnical information and overall site optimisation. Because the package allows teams greater access to project data, issues such as clashes or design changes can be dealt with more quickly and efficiently, reducing the time needed to resolve problems. The package also allows users to consider a variety of different options for a project, evaluating the respective engineering and cost implications and finding the best solution. Comprehensive analysis of design alternatives allows the project designer, contractor and client to collaborate on decision-making processes as a project evolves.

Finalists in the Bentley awards had all used the OpenRoads package in handling projects, with AECOM’s work to upgrade the E4 route in Sweden being a case in point. The project to widen the route to highway status was complex and involved the participation of 70 personnel across 15 sub-consultants in four different countries. The OpenRoads package was used to define the civil software standards across the design teams and improve communications between the separate participants. With 3D models, the team members were able to detect clashes early in the project cycle and resolve issues, reducing problems from errors in the field.

With the route extending for around 31.5km and including 28 bridges, there were many issues to resolve. Many of the bridges were too narrow to cope with the widened highway and were in need of replacement, while nine of the structures could remain. The designers were required to use as much of the existing carriageway as possible, so as to minimise the quantity of road construction, paving and materials required. There were also 34 areas containing archeological remains and a high voltage cable underground that the project designers had to ensure would remain undisturbed by the construction work. A key factor of the project was to minimise the impact to the environment for the project, which was highly complex. A member of the project team said, “It’s about how you manage the information.”

The project team split the work into assets and put the data into master models. Around 100GB of data from point clouds was downloaded to optimise the work. Overall, the team was able to save up to 100hours on the civils, and from this were able to utilise these new skills in optimising ramps and exit design and look at various options, resulting in further time savings.

The Bentley software has been used on the Herning-Holstebro road project in Denmark for the Danish Road Directorate. This has been used as a full-scale trial for the use of digital tools in road construction and also to help establish the digital standards that will allow BIM to be used for projects in the country. The work is underway at present and the contractor is employing machine control technology, using programming based on the digital models.

This 39km project involves the construction of eight interchanges and four railway crossings as well as five landscape bridges. Worth some US$580 million, the project has required participation with several other organisations, this process aided by the ease of file sharing. Because so many different groups are involved in the project, the decision was taken to share these digital models across the team and this approach has helped reduce design time and find any problems early on.

Bentley’s software has also been used on the A6 project in Manchester, involving widening the main route linking the city with its airport. Much of the design work is being carried out by

To improve efficiency the team holds interdisciplinary meetings at regular intervals. Clash reports are relayed back to the team, which was able to resolve 3,800 clashes over the first year. The team uses a novel process with ‘soft’ clashes, allowing 200mm between features as this maximises the use of the whole working area. By eliminating the ‘hard’ clashes, the design team estimates that it saved over £1 million in construction costs, while also delivering a safer project. According to the partners, the use of the 3D models has allowed the designers a greater understanding of the construction work, and the contractor a better understanding of the design.

As Gronmij is a member of the

In choosing the winner from these three highly innovative projects, the jury faced a tough decision. However Grontmij’s innovation with the design of the A6 widening work was decided to have the edge over the other projects and it was awarded the winning place in the Innovation in Roads category.