SaMoTer exhibition presents Cantiere Digitale

A new Ammann asphalt plant in Australia

Safer roads win awards

New Chinese expressway projects planned

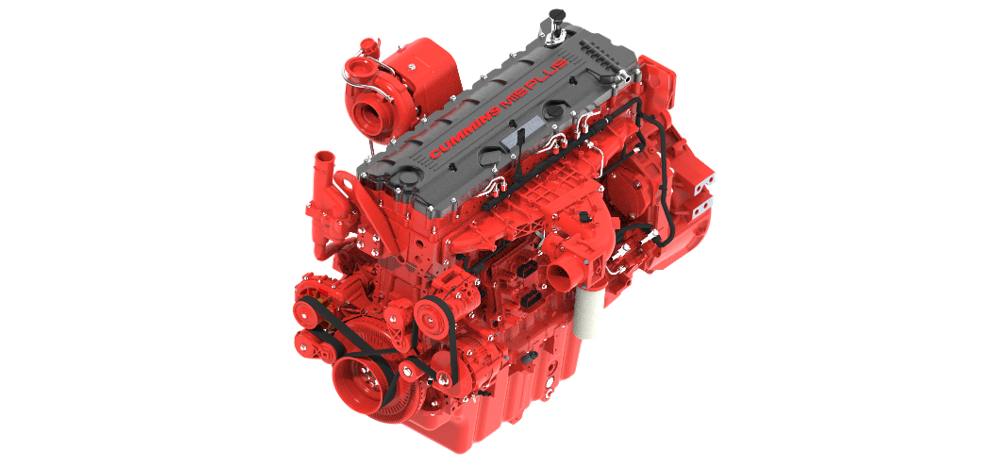

Cummins PLUS engines for China

India-China border roads programme

Svevia in Fjälkinge and Gualöv motorway deal

Drum steer compactors introduced

Messina Strait bridge study complete

Nordøyvegen project wins Norway civils award

Nira and Univrses in Swedish road data project

Ohio Turnpike upgrade works commencing

Chicago’s expressway upgrade underway

Bonjour bio-based binders

Liebherr’s record year – 2022

Bulgarian highway tenders opening

Zimbabwe highway bidding underway

Cat’s new AP 455 world paver will offer different screeds to suit the needs of each local market

Power for the tractor unit comes from a Cat C3.6 diesel rated at 90kW and which meets the Tier 4 Final/Stage V emissions requirements, with a new variable speed fan to help with cooling. The AV47 screed variants are made at the Caterpillar plant in Minnesota while the tractor unit is manufactured in the firm’s Chinese facility.

The machine is available with the SE47VT screed, a tamper bar model for the international market. Meanwhile, the SE47V screed is a vibration only unit aimed at customers in North America, though it will also suit market needs in Latin America and Australia. The firm also offers the SE47FM front mount screed as an alternative.

Users of the version for North America with the SE47V screed can set up the screed using improved controls mounted on either side. Meanwhile the version with the SE47VT tamper bar type integrates the controls in one unit. The version with the SE47VT screed also benefits from the firm’s PaveStart system, which retains the screed settings used for a job. This allows the machine to be restarted with the same screed settings after a break in working or a following day.

Full hydraulic screed extension for all the variants is 4.7m, which can be extended to 6m for the tamper bar variant for example. A proportional control is fitted for the screed extension and retraction and the machine is supplied ready for use with 3D controls.

An improved feature of the new AP 455 is an integrated generator delivering 25kW and which powers the 240V AC heating system. The improved screed heating system offers a fast heating up time, having the machine ready for use in just 20-25 minutes according to the firm.

Vaisala visibility sensors for Arizona

Uganda’s capital Kampala receiving road upgrade