Highway degradation and surface water pollution in an environmentally sensitive area of the Scottish Cairngorms Mountains, famous for its whisky production, are said to have been tackled with an innovative SuDS Solution from Hydro International. Poor drainage, flooding and freezing weather had led to a landslip and extreme surface degradation along a section of the narrow A95 that descends on a 10% gradient with tight bends to the beautiful village of Craigellachie on the River Spey, near Elgin. Situated im

Highway degradation and surface water pollution in an environmentally sensitive area of the Scottish Cairngorms Mountains, famous for its whisky production, are said to have been tackled with an innovative SuDS Solution from Hydro International.

Poor drainage, flooding and freezing weather had led to a landslip and extreme surface degradation along a section of the narrow A95 that descends on a 10% gradient with tight bends to the beautiful village of Craigellachie on the River Spey, near Elgin.Situated immediately above the River Fiddich, a tributary of the River Spey and a Special Area of Conservation, the area is also world-renowned for the production of single malt whisky and is an important salmon fishery. Control of any surface water runoff would therefore have to include measures which maintained the clarity and purity of the water.

After working with

Investigations as part of Transport Scotland’s upgrade of this section of the A95 Aviemore to Keith Trunk Road, revealed that surface water flowing down the steep hillside had been infiltrating the road foundation structure along the 0.9km stretch near Craigellachie. The water flow had been washing away the aggregate layers and causing a loss of load bearing capacity, leading to premature wear, edge deterioration, and in one location a landslide that resulted in a retaining wall being constructed.

“Just addressing the road reconstruction without considering the water flow would have resulted in the erosion problem recurring in a few years’ time,” said Darren McLennan, senior engineer at BEAR. “We also couldn’t afford to have the water flowing over or under the road structure which could create icing problems in the winter or the risk of further landslips.”

Under the Water Environment (Controlled Activities)(Scotland) Regulations 2011, the drainage from major roads must be subject to control of any diffuse pollution to help meet the objectives of the EU Water Framework Directive. There were also concerns on the potential of the reconstruction work affecting the water environment, so care was needed to prevent any accidental pollution.

Other restrictions, under the General Binding Rule 10 of The Scottish Environment Protection Agency (SEPA), stipulate that any road construction must be drained by a SuDS scheme to ensure flow and pollution control. SEPA Pollution Prevention Guidelines 5 and 8 look for at least two forms of treatment to the surface water runoff.

“The road is cut very tightly into the hillside, which limits the construction space along much of the stretch of road although there is a small lay-by set into the hillside around the middle of the scheme. There are also a minor road and farm entrance which complicate the road drainage solutions,” added McLennan.

Simply improving the ditch volume and water retention with a conventional approach such as cast concrete channels was not considered an option due to space within the highway boundary. Also, the lack of flow control would risk additional sediment being washed into the river.

“Hydro was able to design a minimal maintenance SuDS solution providing the required levels of treatment and combining effective flow control with efficient removal of sediments and any hydrocarbon contaminants,” said McLennan.

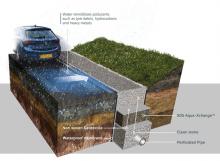

The basis of the scheme, undertaken by contractor, the Coffey Group, was to excavate and deepen the existing ditches. These were lined with heavy-duty polyethylene to prevent seepage into the road structure then filled with carefully graded filter drain aggregate. Flow through the new channels is limited by a series of check dams before eventually discharging into a new pipeline constructed under the road.

The water flow in the pipeline is controlled by a series of three Hydro-Brake Flow Control devices, located at 300m intervals in weir wall concrete chambers under the road. The controlled discharge of the maximum design flow of the Hydro-Brake units also enables the pipeline to be used as a temporary storage chamber to help mitigate storm events.

The last of the three Hydro-Brake units is located at the downslope end of the pipeline, in front of the Hydro Downstream Defender. This device ensures high sediment retention even during storm events, with no re-entrainment, while controlling floatables and providing hydrocarbon separation. The Downstream Defender discharges over a reinforced rip rap face set into the embankment to control erosion, and then to the river.

“The result is an elegant solution which meets both the environmental concerns and the serious structural problem,” concluded McLennan.