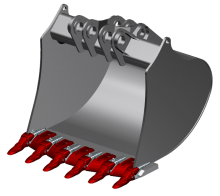

The pre-assembled lips come with the adapter already welded, with the teeth and lockings assembled. Pre-assembly makes it easier for users to repair or replace lips in excavator buckets and will facilitate stock management, while reducing the downtime of machines when replacing or repairing worn excavator-bucket lips, says Alfonso Quezada, product manager for MTG.

The current range includes lips for 20 to 120 ton buckets, as well as alternatives for heavy duty applications with welded shrouds and bottom leg adapter shrouds.

MTG's pre-assembled lips are already available for the North American market and the company is planning to extend the range to other regional markets over the coming months, says Quezada.

Also at CONEXP-CONN/AGG, MTG showed its new range of ProMet wing and blade shrouds that are designed for increased wear life and improved bucket performance in 30 to 85 ton excavator and loader buckets.