The system is said by GKD to have been developed to meet a need for incline monitoring in the construction and utility maintenance industries, particularly for smaller excavators, which carry a higher risk of overturning when operating on inclines.

Allowing the operator to work safely and with confidence within the defined incline limit for the machine, the Incline Alert gives an audible and visual warning on approach to the incline limit. The system is said to consist of a sensitive and accurate pitch and roll angle sensor mounted on the excavator or plant body. It also has a display at the operator station and, according to GKD, it’s easy to install and calibrate.

When the machine angle is beyond the defined limits, warnings from the Incline Alert are triggered and can be used to drive an external alarm or beacon, or to link to a third party device, such as a GPS Tracker, to give remote warning that the machine is being used beyond its defined incline limits.

Should the machine overturn [defined as being at a greater than 50° degrees incline], the Overturn Sentinel System activates, where a flashing red LED on the display is triggered, which can only be turned off by an authorised engineer. This feature is said by GKD to make it possible to tell at a glance whether or not the machine has overturned while in use.

Another product new to the market and being exhibited at Plantworx 2013 is Site Zone from

Site Zone is a proximity warning system using advanced RFID technology. It surrounds a vehicle with an invisible 360° detection zone. When this zone is breached by personnel wearing a Site Zone transponder, the driver is alerted to the risk via an audible and visual alarm. There is also an optional warning alert for pedestrians. Ongrade claims that Site Zone is not dependent on line of site and can detect transponders around blind corners and other obstacles.

Said to be deployable on almost any type of plant from forklift trucks and mini excavators through to wheeled loader, large excavators, bulldozers and even larger plant such as ADTs, Site Zone detection zones are customisable and the system has an adjustable range of up to 10m.

Not only is it said to be able to prevent accidents, Site Zone is also said to be able to change operator behaviour, partly due to its data logging feature. Each breach is recorded in the system memory which can be downloaded and used to identify individual training needs or areas requiring operational improvement.

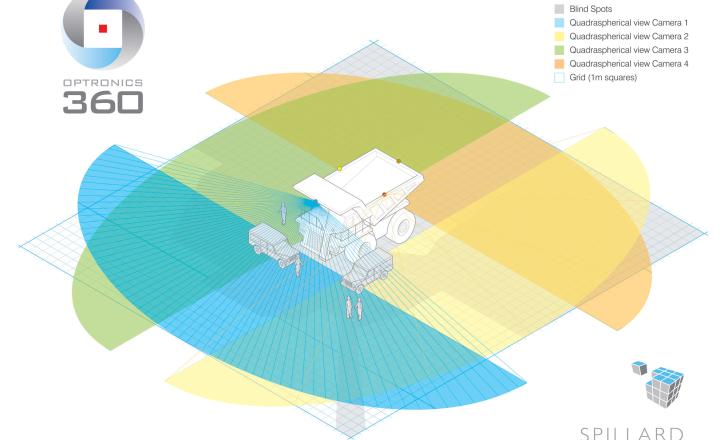

A third Plantworx 2013 featured safety solution will be Spillards’ new Optronics 360. The 360° surround view camera system for industrial and commercial vehicles is said to eliminate blind spots ensuring the driver can see all round the vehicle. Optronics 360 consists of a combination of a camera system, a monitor and a high performance programmable electronic control unit (ECU) using heavy duty signal processing to overcome distortion.

The system is currently in use in the high end passenger car market on the

Benefits of the Optronics 360 are said to extend beyond helping to prevent injuries to people; it is also said to reduce or eliminate collisions with other objects, such as site vehicles, and can minimise tyre damage, particularly when reversing, as it enables operators to see and avoid objects lying on the ground.

Optronics 360 can also be programmed from horizon to horizon as well as forward and rear.