The new Loadrite 360° management system has been designed to boost efficiency in quarries by integrating communication across all stages of an order for faster turnarounds and maximised payloads. Loadrite said that the system improves communication throughout the load-out operations. It is aimed at providing quarry managers with the tools they need to get the most from both staff and equipment. Benefits include lower costs per tonne and optimised truck utilisation, said the company.

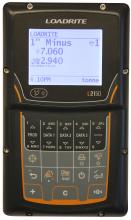

The new 5004 Loadrite 360° management system has been designed to boost efficiency in quarries by integrating communication across all stages of an order for faster turnarounds and maximised payloads.

Loadrite said that the system improves communication throughout the load-out operations. It is aimed at providing quarry managers with the tools they need to get the most from both staff and equipment. Benefits include lower costs per tonne and optimised truck utilisation, said the company.

Loadrite 360° integrates with the existing ticketing system and there is an automated communication link between the weighbridge and the loaders. It handles every step, right from the customer placing the order and it being entered into the system. The system also provides real-time visibility of traffic on the site and feedback on the accuracy of loads. It can also be used to study historical analysis and produce reporting of key performance indicators.

2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Loadrite said that the system improves communication throughout the load-out operations. It is aimed at providing quarry managers with the tools they need to get the most from both staff and equipment. Benefits include lower costs per tonne and optimised truck utilisation, said the company.

Loadrite 360° integrates with the existing ticketing system and there is an automated communication link between the weighbridge and the loaders. It handles every step, right from the customer placing the order and it being entered into the system. The system also provides real-time visibility of traffic on the site and feedback on the accuracy of loads. It can also be used to study historical analysis and produce reporting of key performance indicators.

Stand: C2.121

%$Linker:

%$Linker: