John Deere Power Systems unveiled its solution for EU Stage IV emissions regulations at INTERMAT.

It saw the company introduce an SCR catalyst and diesel exhaust fluid dosing unit to its Stage IIIb engine platforms from 56-560kW. “SCR was not our preferred technology path but it has proved to be the best way for us to maintain particulate levels while reducing NOx to meet EU Stage IV emissions regulations,” explained Xavier Adam, market planning manager for John Deere Power Systems.

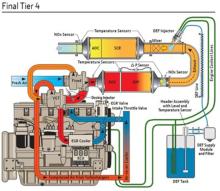

To meet Stage IV emissions, Deere has opted for an SCR solution

It saw the company introduce an SCR catalyst and diesel exhaust fluid dosing unit to its Stage IIIb engine platforms from 56-560kW.

“SCR was not our preferred technology path but it has proved to be the best way for us to maintain particulate levels while reducing NOx to meet EU Stage IV emissions regulations,” explained Xavier Adam, market planning manager for John Deere Power Systems.

Integrating existing cooled EGR engine technology, DOC and DPF components with diesel exhaust fluid and an SCR catalyst, Deere has reduced fuel consumption and maintained transient response times. And the engine’s ECU determines the most appropriate combination of these technologies according to engine loads.

“We have reduced fuel consumption from 1-3%, while injecting between 1-3% diesel exhaust fluid,” said Adam. “So customers will not have any overall change to their fluid costs.”

But there are increased maintenance requirements for the system. A diesel exhaust fluid filter needs periodic replacement and the DPF will still need its ash content removing. Though Deere’s experience suggests that 8,000hour ash cleaning intervals are now achievable with its DPFs.

%$Linker:

Hall: 5B Stand: L002