The European Green Deal sets up a series of ambitious targets, such as climate neutrality by 2050, with an interim goal of reducing emissions by at least 55% by 2030. These objectives seriously impact different sectors, among which is the road infrastructure industry.

At the international level also, the road community has identified climate change adaptation and decarbonisation as key objectives. For example, PIARC - the World Road Association - has embedded them in its own strategic plan.

But sustainability is often easier to say than do and many stakeholders in the road industry and road administrations may wonder where to begin the voyage. Sometimes small things can produce big results. Other times, it takes a lot of strategic policy planning to get even small results.

During a UK case study on sustainability, it was found that to embed sustainability into a project, right from the start there needs to be a “sustainability culture” within a client’s procurement team. There should be a drive to publish a project’s carbon budget that has specially laid out targets for reducing carbon emissions, said Andrew Warrington, senior technical director with consultancy Arcadis.

To begin the sustainability voyage, it sometimes takes someone to think out of the box a little, as did Nejan Hatko, general manager of the Turkish barrier maker Hatko Sound Barriers. Two pollutions can make one solution, he said during his presentation and speaking on behalf of the European Noise Barrier Federation, of which his company is a member. Hatko explained how recycling material – in his company’s case, end-of-life road tyres – can begin a company’s journey to carbon neutrality.

The beauty, he said, is that the problem of used tyres going to landfill (or being burned in the worst case scenario) have been re-purposed. They are now being used to mitigate noise pollution, much of which they were making in their useful life. As part of sustainability programmes, barriers can be made pleasing to eye, even coloured green. This has been done in Turkey, on prestige projects including the Northern Marmara Motorway.

Tyres and noise were also the subject of a presentation by Ottavia Calamani, the former international business development manager at AISICO and, since this May, the company’s chief executive. The company, based near Rome, is a crash test specialist but also a research and laboratory for the road sector. It has started conducting mobile road noise detection studies – acoustic absorption of tyre rolling noise. Road noise comes in three types – propulsion noise from the engine, aerodynamic noise from as vehicle moving through the atmosphere and tyre noise from contact with the pavement – the worst emitter of noise pollution. Importantly, she said, tyre noise usually exceeds the maximum safe noise level for those people living close to highways.

Using the Close Proximity Method of noise measurement, AISICO has been driving around roads using a van fitted out with sensors and microphones inside and outside. It’s has been collecting data at various proximities to the pavement, as close as only a few centimetres from the road surface.

Kaan Kaptan, director of operation and maintenance for Istanbul’s Eurasia Tunnel, presented his project’s case for sustainability. The tunnel has completed a pilot project for the OECD (Organisation for Economic Cooperation and Development), for its Blue Dot Network sustainable certification for quality infrastructure. The Blue Dot Network is a multilateral organisation that promotes a certification framework for quality infrastructure projects. The initiative is a joint project of the governments of Australia, Czech Republic, Japan, Spain, Switzerland, UK and US. It supports investment in high-quality infrastructure projects, especially by the private sector.

To be certified, a project must promote sustainable and inclusive economic growth and development. It should promote market-driven and private sector led investment as well as support best-practice use of public funds. It should also support sound public financial management, debt transparency and project-level and country-level debt sustainability.

On the physical side, the project must be resilient to climate change, disasters and other risks, and aligned with the pathways towards 2050 net-zero emissions. It should ensure value-for-money over an asset's life-cycle cost and advance inclusion for women, people with disabilities and underrepresented and marginalised groups.

Istanbul’s Eurasia Tunnel meets these criteria, said Kaptan. He pointed to the facilities own solar power plant, its use by staff of electric and hybrid vehicles and its carbon neutral certification with ISO 14064 for 2021 to 2023. Meanwhile, its use of high-tech lighting such as pacemaker in the tunnel keeps traffic moving, thereby reducing congestion and vehicle emissions. Tunnel ventilation is also optimised, meaning it works according to the traffic requirements and so saves on operating costs.

Meanwhile, Murat Gucuyener, chief technical officer for the Eurasia Tunnel, praised the use of public-private partnerships, such as for the project. However, he noted that for incorporation of sustainability principles there is still a gap in the current PPP procurement process. The criteria for evaluation and selection of a bid needs to be improved. Nonetheless, PPPs remain one of the most powerful tools for ensuring a project’s total sustainability certification.

When it comes to choosing material for road infrastructure, such as a barrier system, Claudio Cofano, application development manager of ArcelorMittal Global R&D, said low-carbon steel is proving it can help a manufacturer reach its sustainability goals. Steelmaking is going through a de-carbonisation revolution where it is stronger and lighter than normal blast furnace-produced steel. Furthermore, the weight reduction can result in up to 14% less transportation cost for the product.

Around 90% of a steel product’s emissions are produced during the normal iron-making stage – the blast furnace stage – said Cofano. ArcelorMittal’s XCarb offers between 60% and 70% CO₂ reduction. Alongside the new XCarb brand, the company has launched three XCarb initiatives: the XCarb innovation fund, XCarb green steel certificates and XCarb recycled and renewably produced for products made using the electric arc furnace route using scrap.

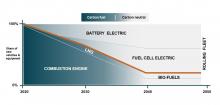

While not a major issue at the moment, road designers will likely have to consider more land beside the highway to set up electric vehicle charging stations. Just how big will these EV parking lots need to be, asked Jan Pettersson, director for the electric road programme at the Swedish Transport Administration. The answer to this is not very big if in-road charging can be developed.

On-the-move charging can be by induction – through non-contact coil-to-coil interaction – or conduction where a vehicle has a conductor make contact with a buried rail along the road. There is also the cantenary system of overhead cables onto which a large truck would make contact. All systems would run for several kilometres along a road. Charging like this can boost a driver’s confidence about reaching destinations further afield. Distance anxiety is relieved, said Pettersson, and land use spared.